Hollow silicon dioxide microsphere with different surface configurations and preparation method thereof

A technology of silicon dioxide and surface morphology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of many restrictive conditions, difficult hollow microspheres with different surface smoothness, long reaction time, etc., to achieve simple control methods and control methods. Simple and easy to implement, the effect of short reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

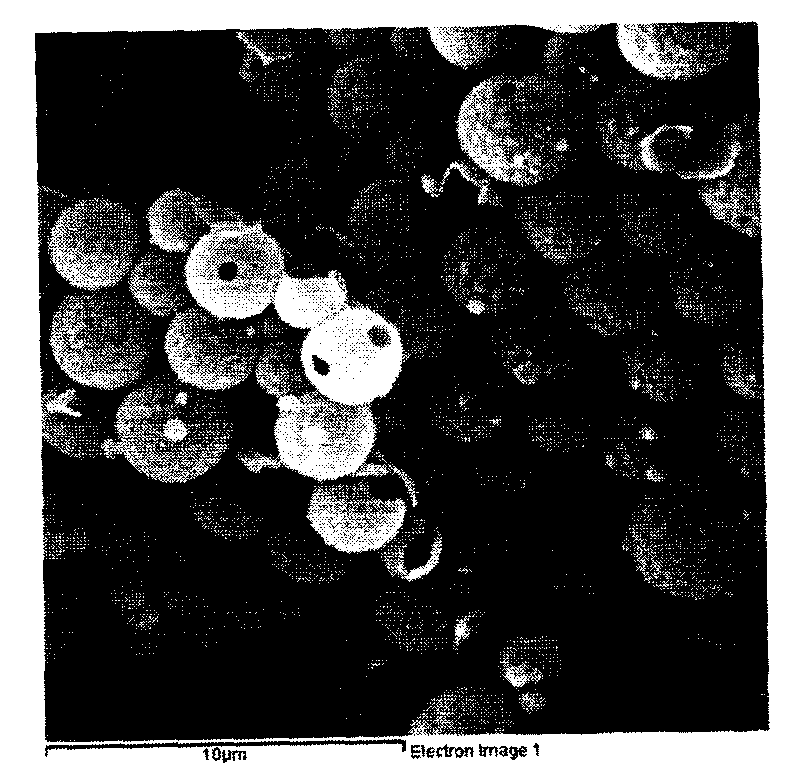

[0034] according to figure 1 (5000 times SEM), hollow silica microspheres: diameter 1-3.5 μm, shell thickness 75nm, silica nanoparticles constituting the spherical shell are closely connected, and the surface of the microspheres is rough (5000 times).

[0035] Preparation method of hollow silica microspheres with high roughness:

[0036] 1) Take 4g polystyrene microspheres (PS) microspheres in a beaker, add 0.64mol methanol and 1.25molH 2 O middle;

[0037] 2) After stirring for 30 minutes, add 0.055mol / L cetyltrimethylammonium bromide (CTAB);

[0038] 3) After continuing to stir for 30 minutes, add 0.011mol tetraethyl orthosilicate (TEOS) and 11mol NH 3 ·H 2 O;

[0039] 4) Stirring and reacting for 1 hour; the silicon dioxide nanoparticles generated by hydrolysis of TEOS are connected and coated on the surface of polystyrene microspheres (PS) as templates;

[0040] 5) Suction filtration, washing until the clear liquid after suction filtration has no foam;

[0041] 6) Dry...

Embodiment 2

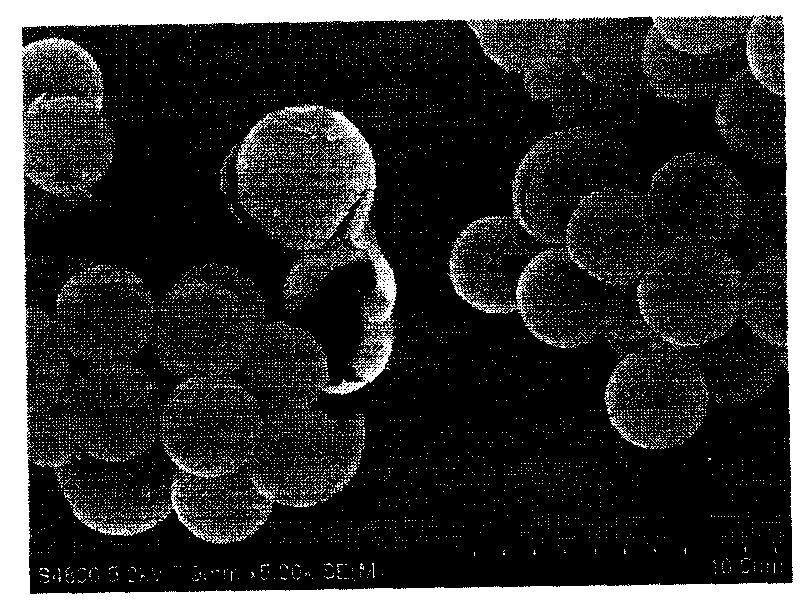

[0043] according to Figure 2a (5,000 times SEM), b (50,000 times SEM), hollow silica microspheres: diameter 1-3μm, shell thickness 67nm, specific surface area 461m2 / g, pore volume 0.3216ml / g, the carbon dioxide that constitutes the spherical shell There are nanopores in the silicon nanoparticles, the pore diameter is 2.24nm, and the surface roughness of the microspheres is relatively high.

[0044] Preparation method of hollow silica microspheres with higher surface roughness:

[0045] 1) Take 8g polystyrene microspheres (PS) microspheres in a beaker, add 0.64mol ethanol and 1.25molH 2 O middle;

[0046] 2) After stirring for 30 minutes, add 0.018mol / L cetyltrimethylammonium bromide (CTAB);

[0047] 3) After continuing to stir for 30 minutes, add 0.011mol tetraethyl orthosilicate (TEOS) and 0.22mol NH 3 ·H 2 O;

[0048] 4) Stir the reaction for 1 hour; the silica nanoparticles generated by hydrolysis of TEOS are connected and coated on the surface of polystyrene microsp...

Embodiment 3

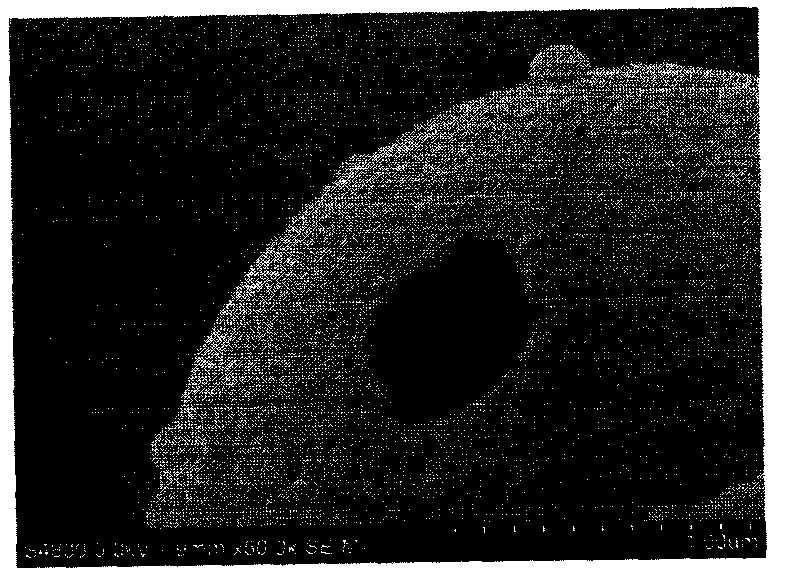

[0052] According to the smooth surface hollow silica microspheres shown in Figure 3, the diameter is 500nm-3μm, and the shell thickness is 89nm. The spherical shell is composed of silica nanoparticles closely packed and connected, and there are nano Pore, pore diameter 2.3nm, specific surface area 1100m 2 / g, the pore volume is 0.7365ml / g, and the surface of the microsphere is smooth.

[0053] The preparation method of hollow silica microspheres with smooth surface:

[0054] 1) Take 6g polystyrene microspheres (PS) microspheres in a beaker, add 0.64mol ethanol and 1.25molH 2 O middle;

[0055] 2) After stirring for 30 minutes, add 0.055mol / L cetyltrimethylammonium bromide (CTAB);

[0056] 3) After continuing to stir for 30 minutes, add 0.011mol tetraethyl orthosilicate (TEOS) and 0.22mol NH 3 ·H 2 O;

[0057] 4) Stir the reaction for 1 hour; the silica nanoparticles generated by hydrolysis of TEOS are connected and coated on the surface of polystyrene microspheres (PS) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com