Magnetic co-sedimentation biological filtering tank process and device

A biological filter and co-sedimentation technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Reduced area, guaranteed stable operation, good impact resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

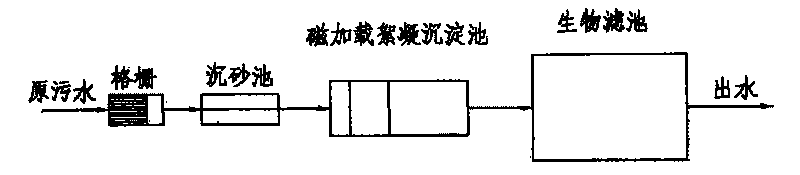

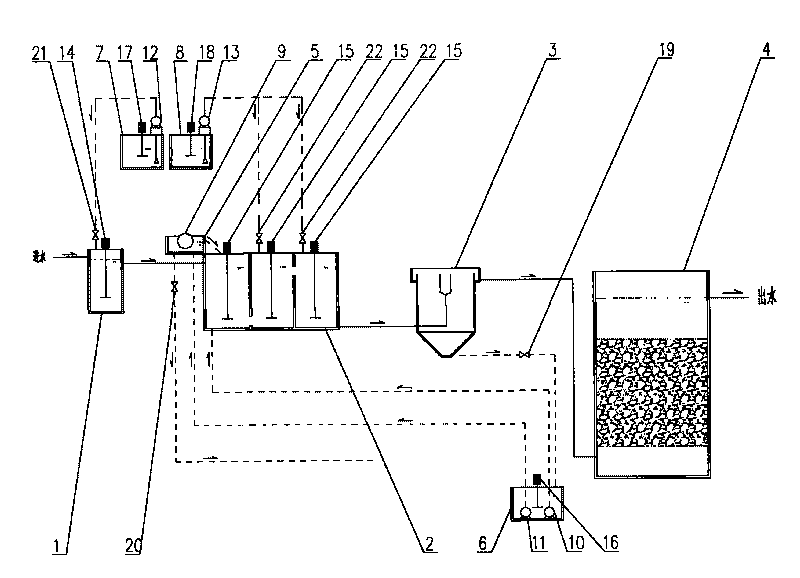

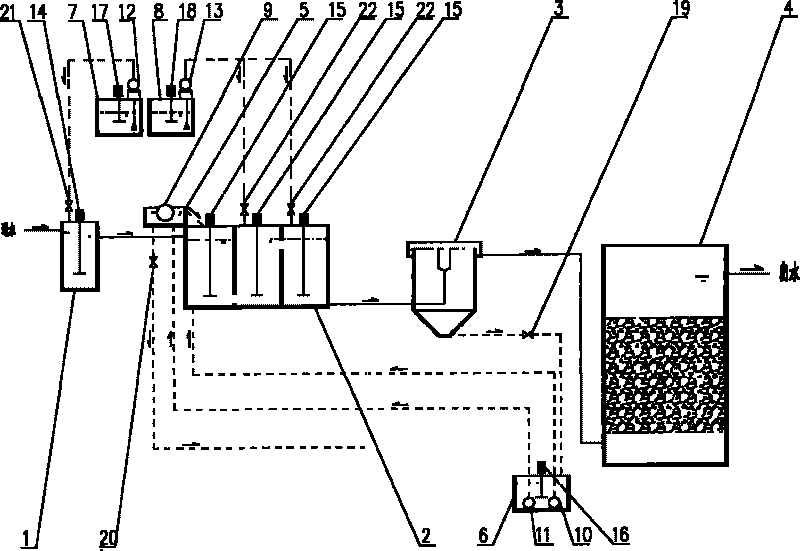

[0009] The present invention combines magnetic loading flocculation sedimentation technology with biological filter technology to form a new process for sewage treatment, that is, Coagulation Magnetic Biological Aerated Filter Technology (CMBAF process for short). The magnetic loading flocculation sedimentation technology achieves a better treatment effect than the first-level strengthening by adding coagulant to the mixing tank, magnetic loading and coagulant aid to the flocculation tank, and then combined with the subsequent biological filter process, so that Sewage treatment meets the requirements of national discharge standards. Technical process of the present invention sees figure 1 , The magnetic loading flocculation sedimentation tank is used to replace the primary sedimentation tank or coagulation sedimentation tank of the biological filter pretreatment process system. After the effluent of the grit chamber of the sewage treatment plant is connected to the magnetic l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com