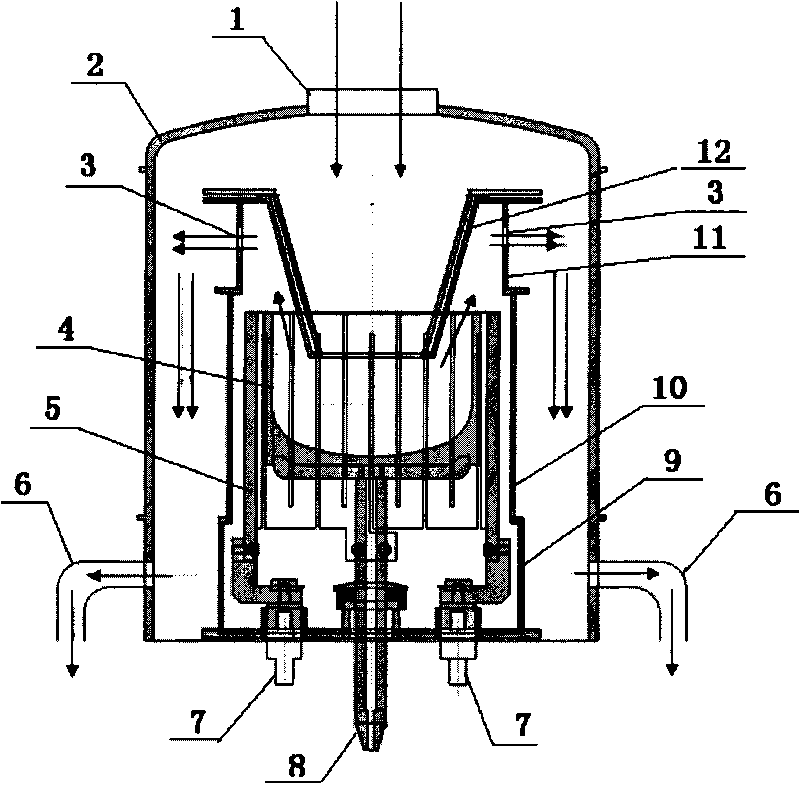

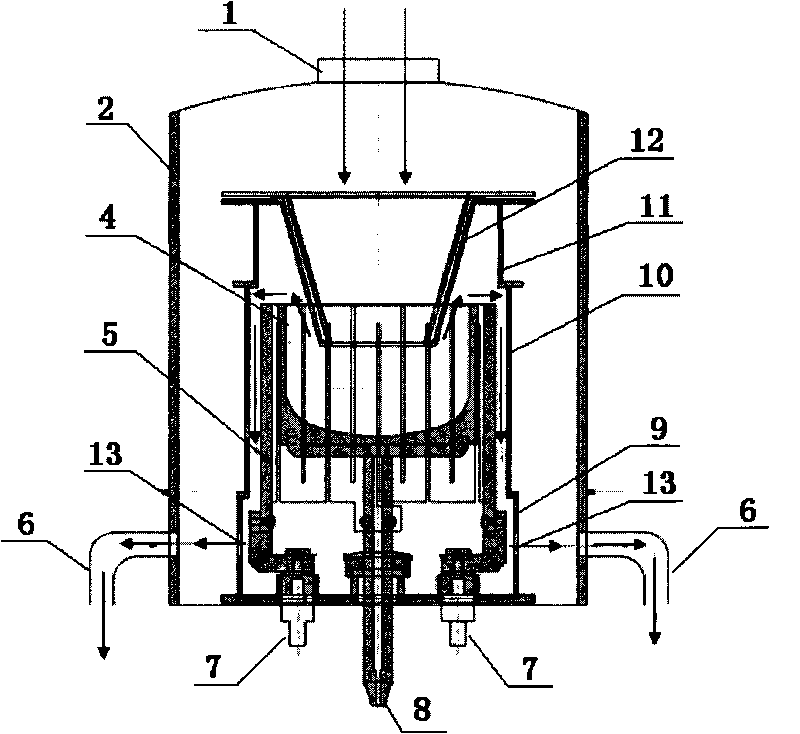

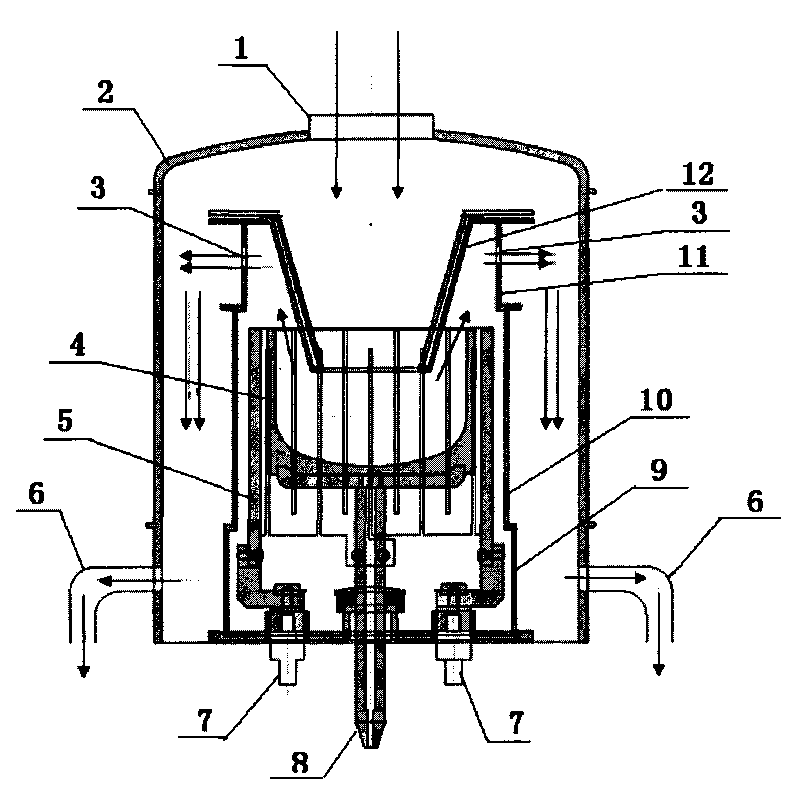

Exhaust method and device of thermal field of single crystal furnace

A technology of an exhaust device and an exhaust method, which is applied in the directions of single crystal growth, chemical instruments and methods, crystal growth, etc., can solve the problems of difficult cleaning of the pipe wall, increase the flow rate and flow rate of cooling water, and thermal field damage, etc. Solve the effect of heat loss, increase thermal insulation materials, and flexible disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0023] Before the exhaust port was changed, the 18-inch thermal field, the feeding amount was 65KG, the length of the six-inch single crystal growth was 1250mm, the production power was 70KW / hour, and the average use times of the graphite crucible was 18 furnaces. After using the design of the exhaust port, the feeding amount 76KG, can produce six-inch single crystal length 1550mm, production power 58 to 62KW / hour, the average number of times of use of graphite crucible with the same mechanism size increased to 35 furnaces.

Embodiment example 2

[0025] Before the exhaust port was changed, the thermal field was 20 inches, the feeding amount was 80KG, the length of the six-inch single crystal was 1650mm, the production power was 75KW / hour, and the graphite crucible was used for an average of 20 furnaces. After using this design of the exhaust port, the feeding amount 100KG, can produce six-inch single crystal length 2100mm, production power 62 to 66KW / hour, the average use times of graphite crucible with the same mechanism size increased to 40 furnaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com