Annular radiation type blazed grating

A blazed grating, radiation-type technology, applied in diffraction grating and other directions, to achieve high diffraction efficiency, extensive social benefits, and good market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

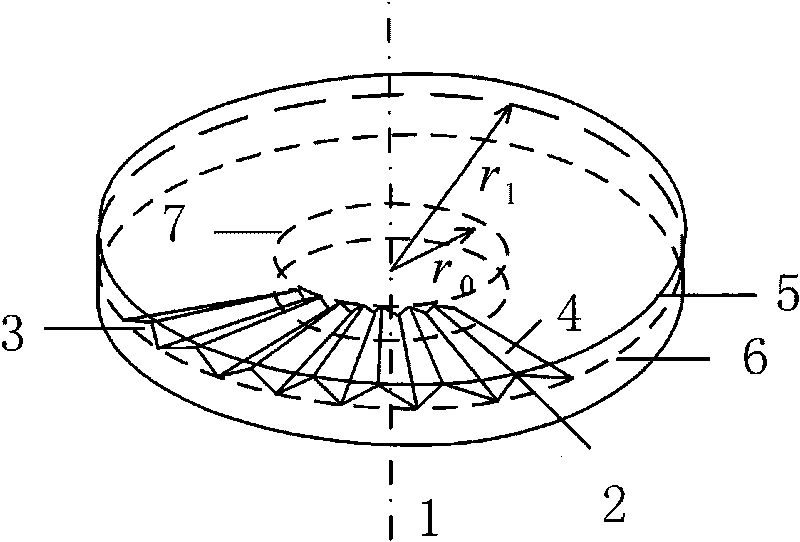

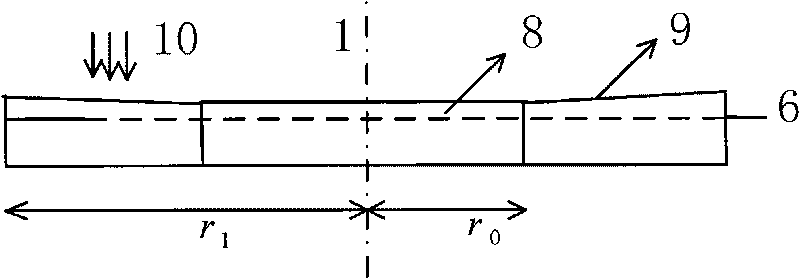

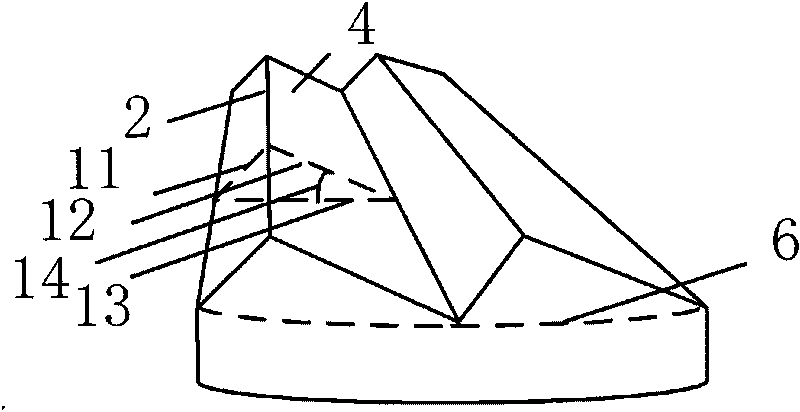

[0018] The realization principle of the technical solution of the present invention is: etching M blazed grating groove teeth on an annular grating substrate, each grating groove tooth has the same parameter, and is periodically arranged at 2π / M rad on the circumference. The projection of each grating tooth on the upper surface is a radian of 2π / M rad, and the radius is from r 0 to r 1 fan-shaped. Each grating tooth on the inner and outer circumference r 0 、r 1 The end face of is a circumferential surface or a plane, because the beam is mainly at r 0 to r 1 Incident on the radius of , so the requirements for the boundary are not high. By designing the blaze angle of the grating, the desired beam deflection angle can be obtained. The contour of the upper surface of the substrate after etching is a conical surface, and the conical surface is in contact with the top of each grating tooth.

[0019] The methods for realizing the grating include ion beam milling, photolithogr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com