Process for fully dehydrating coal under hydraulic coal mining well

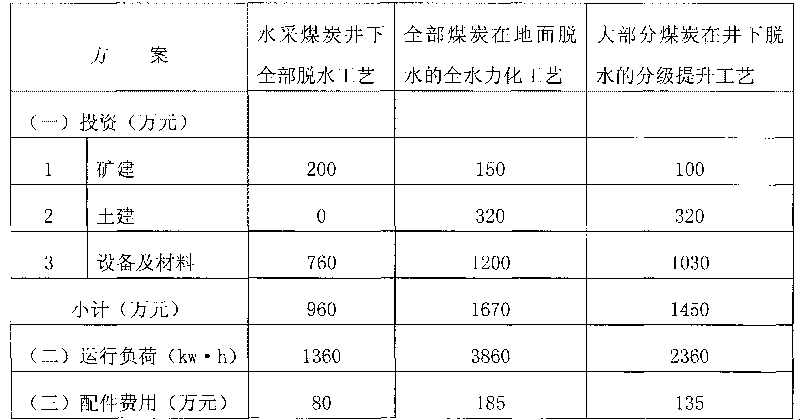

A process and coal technology, which is applied in the field of dehydration of coal in hydraulic coal mining wells, can solve the problems of high maintenance costs, system blockage accidents, short life and other problems, and achieve significant economic benefits, low investment costs, and low accessories costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

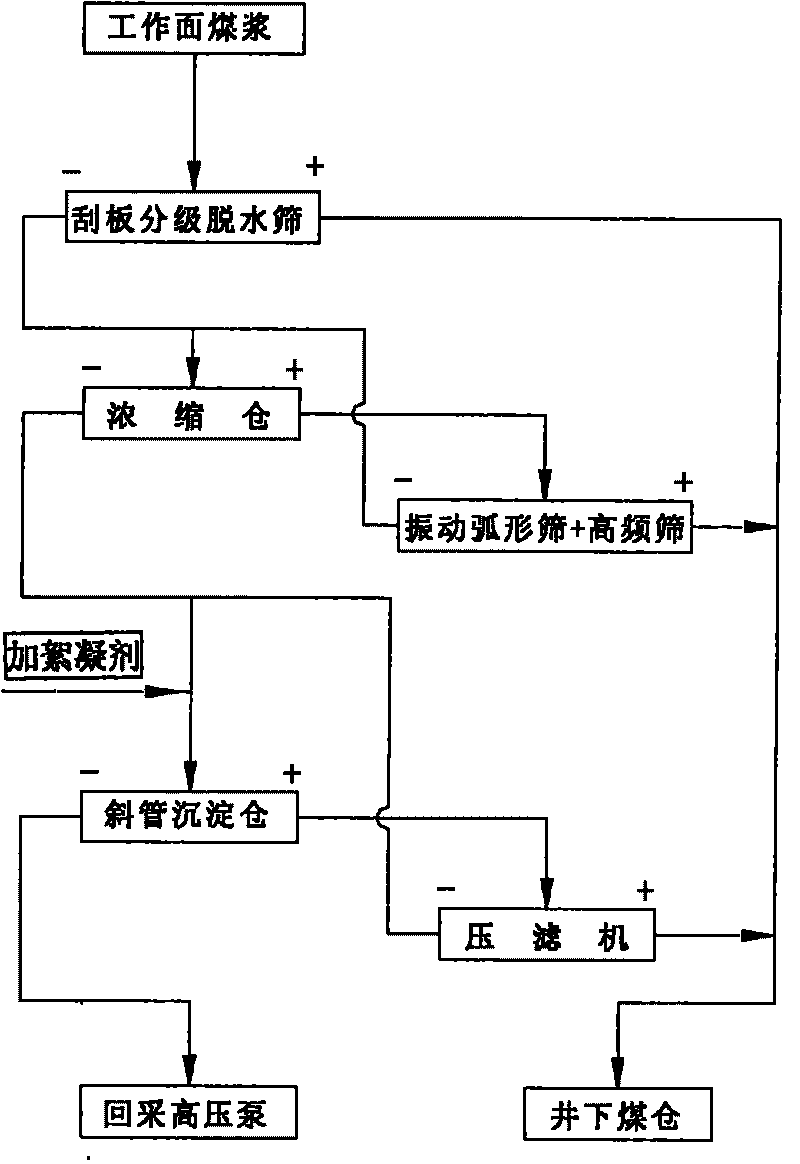

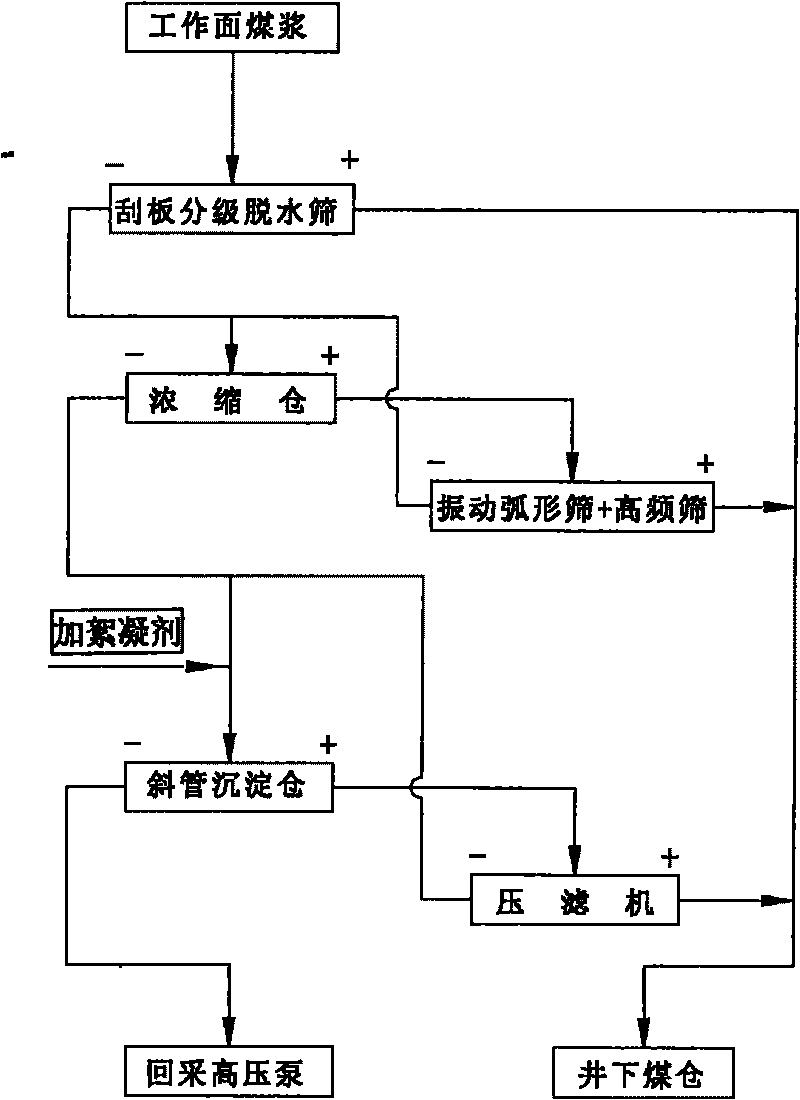

Method used

Image

Examples

example 1

[0018] Example 1: A coal mine mines the No. 3 coal seam, the coal quality is lean coal, and the pH value of the water quality is 7.8. First, add a flocculant polyaluminum, and the addition amount is 30g / m 3 ; The other is a non-ionic polyacrylamide flocculant with a molecular weight of 5.1 million and an addition amount of 3g / m 3 .

example 2

[0019] Example 2: The coal quality of a coal mine is coking coal, and the pH value of the water quality is 6.5. It only needs to add flocculant non-ionic polyacrylamide to meet the water quality requirements. The molecular weight is 8 million, and the addition amount is 5g / m 3 .

example 3

[0020] Example 3: The coal quality of a coal preparation plant is coking coal, and the PH value of the coal mining water is 8.5. First, add flocculant polyaluminium, and the addition amount is 45g / m 3 ; Then add non-ionic polyacrylamide, the molecular weight is 5.1 million, and the addition amount is 4g / m 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com