Device and method for biological processing with pulsed multi-frequency ultrasonic waves in sweep-frequency mode and use thereof

A bioprocessing and ultrasonic technology, applied in the pulsed multi-frequency ultrasonic bioprocessing device and the application field of the deep processing of agricultural products, can solve the problems of not reaching resonance, contaminating the extract solution, difficult to excite the resonance frequency of the processing system, etc. Avoid the generation of standing waves, promote chemical reactions, and enhance the effect of destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

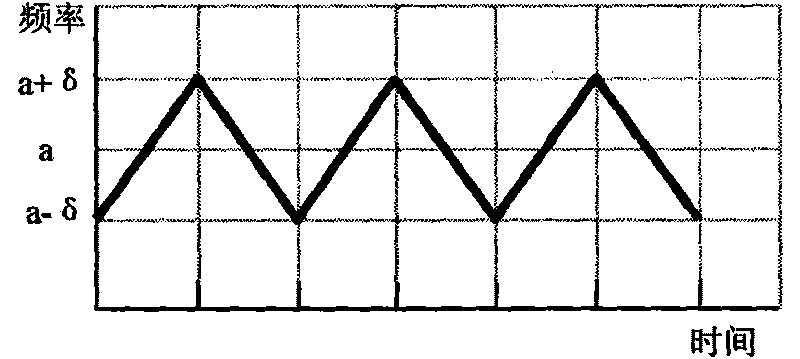

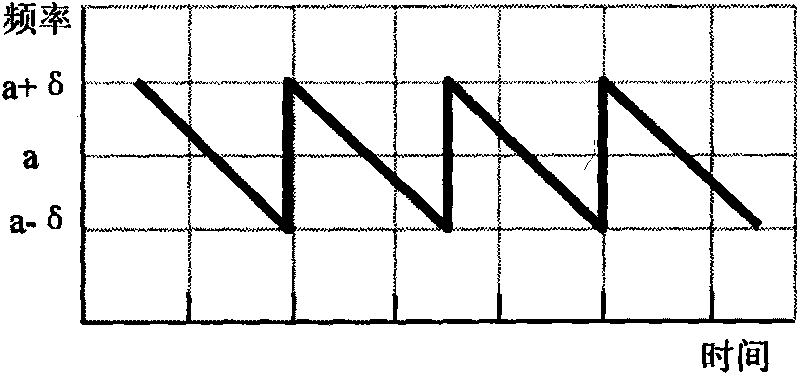

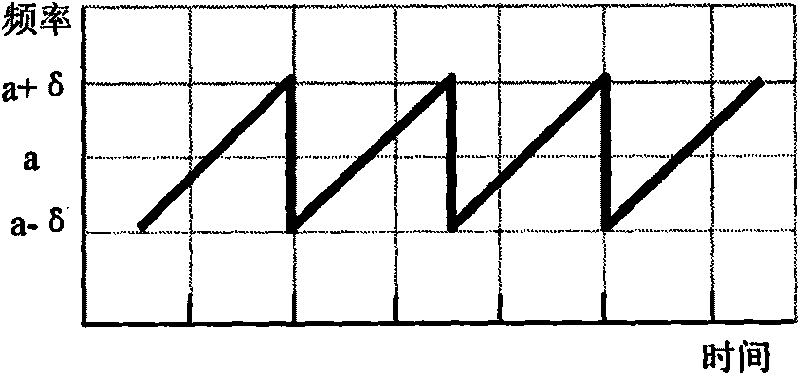

[0046] Application of the present invention in the extraction of effective components of natural products—ultrasound-assisted extraction of Porphyra zebra protein. 1 kg of dry laver (containing 41.3% protein) was pulverized to 60 mesh, mixed with 40 L of water, and added to an ultrasonic treatment tank. Put two transducers with a frequency of 28kHz at the bottom of the treatment tank, and place two transducers with a frequency of 20kHz close to the liquid surface (about 20cm apart). The input power of each transducer is set to 600W (total power of 4 transducers is 2400W), the sweep period is 20ms, the sweep width is ±2kHz, the ultrasonic time of pulse ultrasound is 100s, the rest time is 3s, and the cycle pump is set by the computer. The flow rate is 5L / min, and the initial temperature of the extract is 45°C. Ultrasound-assisted extraction was stopped after 80 min. The extract was centrifuged at 3000 r / min for 10 min, and the supernatant was taken to measure the protein cont...

Embodiment 2

[0049] Application of the present invention in the extraction of active ingredients of natural products—ultrasound-assisted extraction of rapeseed protein. 1.8 kg of rapeseed meal crude protein (containing 48% protein) was pulverized to 90 mesh and mixed with 30 L of water, then added to an ultrasonic treatment tank, and the pH was adjusted to 9.8. Put two transducers with a frequency of 28kHz at the bottom of the treatment tank, and place two transducers of 24kHz close to the liquid surface (about 15cm apart). The input power of each transducer is set to 600W (total power of 4 transducers is 2400W), the sweep period is 18ms, the sweep width is ±2kHz, the ultrasonic time of pulse ultrasound is 50s, the rest time is 5s, and the cycle pump is set by the computer. The flow rate is 16L / min, and the initial temperature of the extract is 30°C. Ultrasound-assisted extraction was stopped after 30 min. The extract was centrifuged at 3200 r / min for 10 min, and the supernatant was take...

Embodiment 3

[0052]The application of the present invention in the extraction of effective components of natural products—ultrasound-assisted synchronous extraction of rice bran protein and polysaccharides. Mix 200g of defatted rice bran and 20L of water and add them into the ultrasonic treatment tank. Two transducers with frequencies of 24kHz and 64kHz are placed in the bottom of the treatment tank. The input power of each transducer is set to 600W, the sweep period is 36ms, the sweep width is ±2kHz, the ultrasonic time of pulse ultrasound is 200s, the rest time is 5s, the flow rate of the circulating pump is 2L / min, and the extraction liquid is set by the computer. The initial temperature was 45°C. Ultrasound-assisted extraction was stopped after 80 min. The extract was centrifuged at 3000 r / min for 10 min, and the supernatant was taken to measure the protein content, and the total extraction rate of protein and polysaccharide was calculated to be 86.2%.

[0053] Controlled experiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com