Multistage monocrystalline silicon square rod surface grinding device

A technology for surface grinding and silicon square, which is applied in the field of multi-station single crystal silicon square rod surface grinding device, can solve the problems of low efficiency, unreasonable structure setting, unsuitability for precision, high efficiency, and mass processing, etc., and achieves Effects of rapid installation, improvement of machining accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

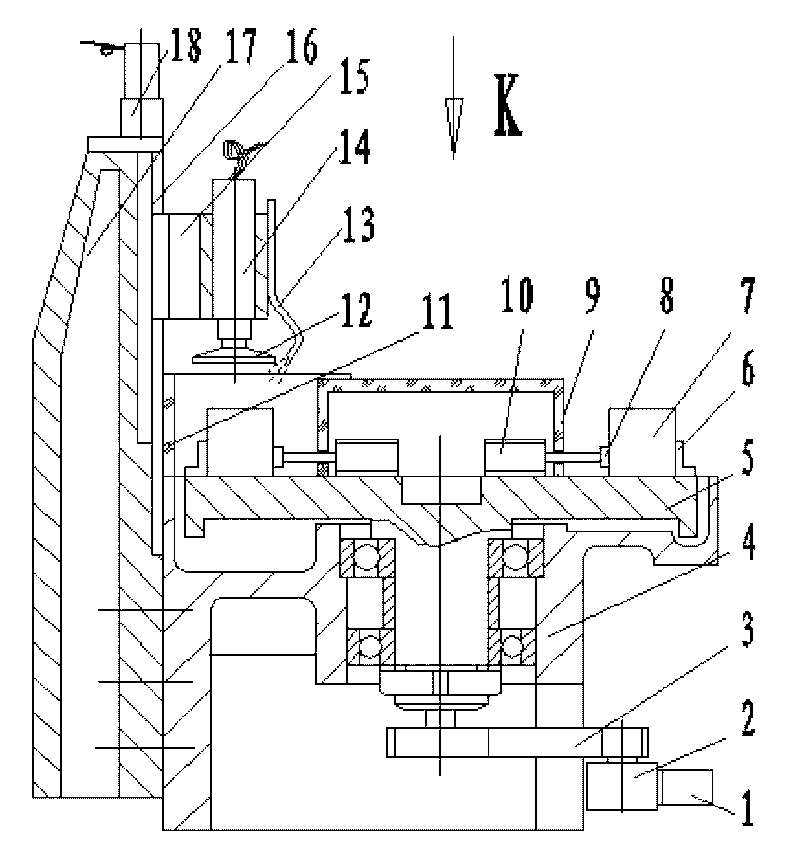

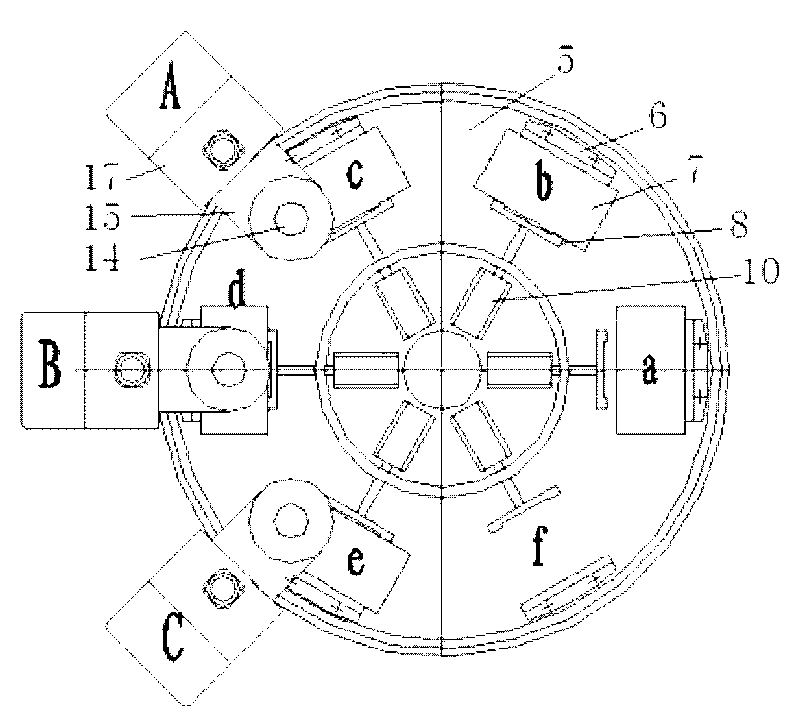

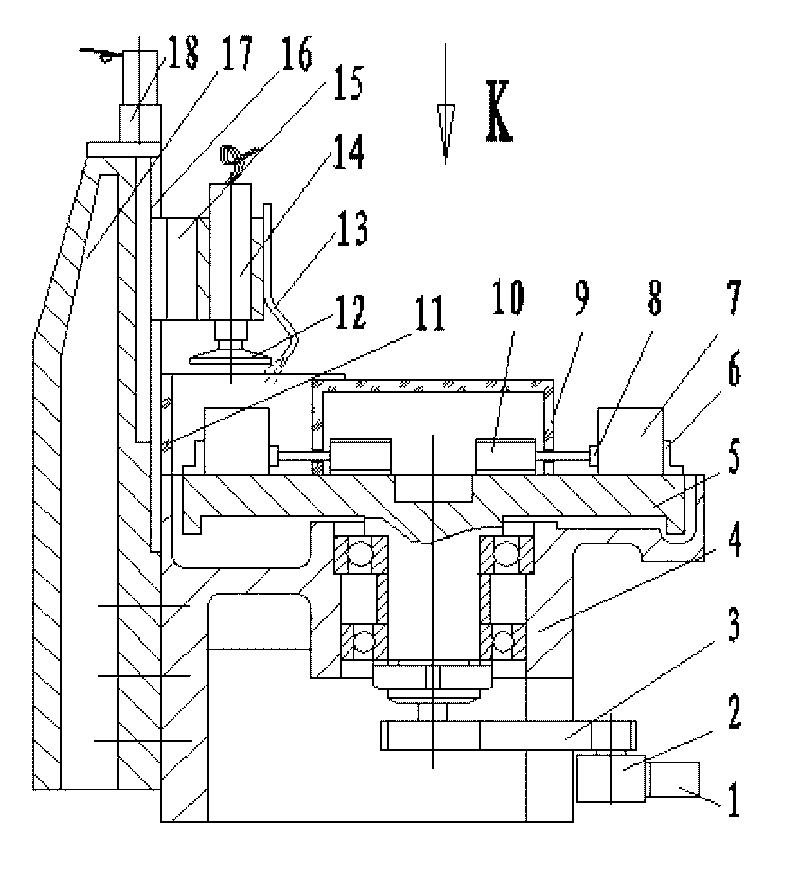

[0016] like figure 1 As shown, the multi-station monocrystalline silicon square rod surface grinding device of the present invention includes a machine base 4, on which a horizontal working turntable 5 is installed through a vertical bearing, and the rotating shaft pulley of the working turntable 5 passes through The belt 3 is sequentially connected with the reducer 2 and the motor 1 to realize the uniform rotation of the working turntable 5, thereby realizing the multi-station continuous processing of silicon rods; a set of silicon rod positioning units are installed on the six equal parts of the upper surface of the working turntable 5 .

[0017] Three grinding units of the same structure are fixedly connected to the side of the machine base 4, each grinding unit includes a column 17, and a sliding seat 15 is connected to the column 17 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com