Gravity inductive type axis-counting device and method for detecting state of tract district using same

A technology of gravity sensing and axle counting equipment, which is applied in the direction of vehicle route interaction equipment, railway car body parts, railway signal and safety, etc., can solve problems such as poor track circuit shunting, and achieve poor shunting, good insulation performance, The effect of a wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

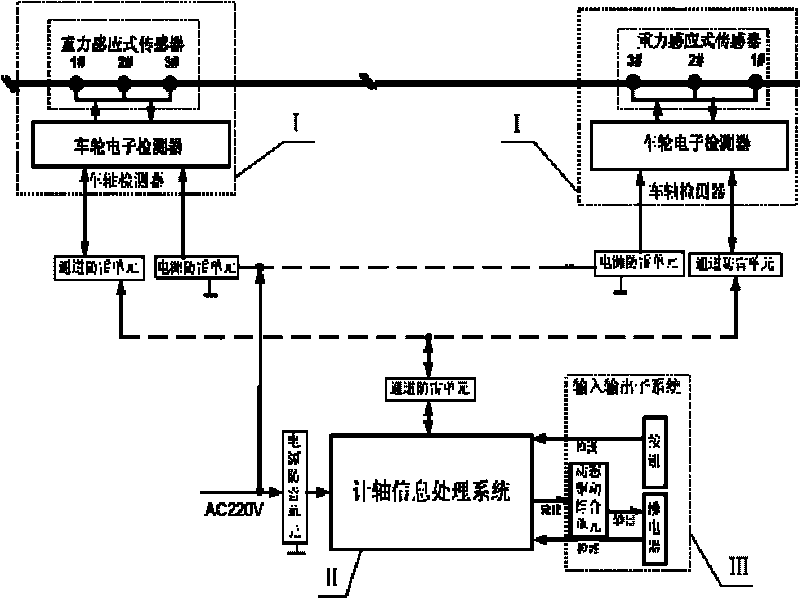

[0047] Embodiment 1: Gravity-inductive axle counting equipment in the station

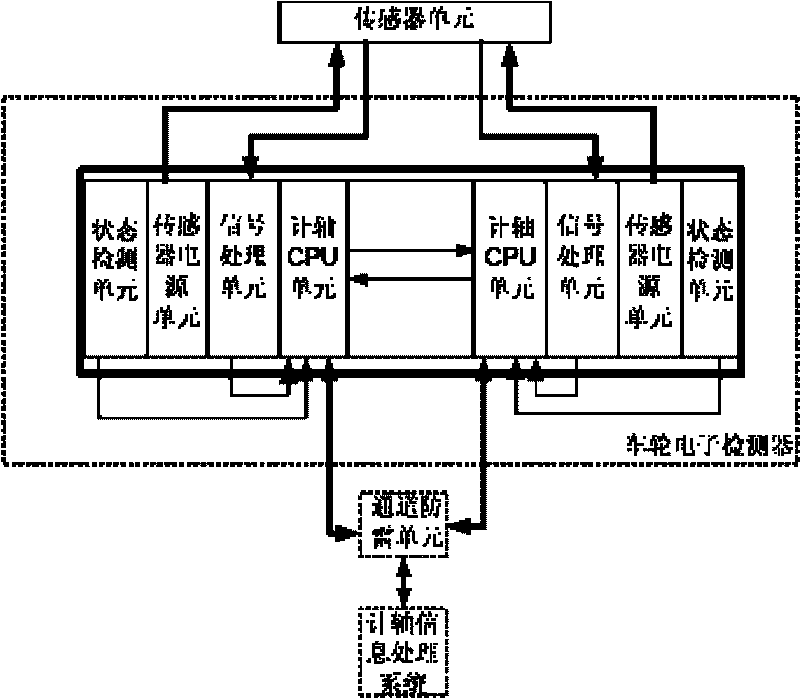

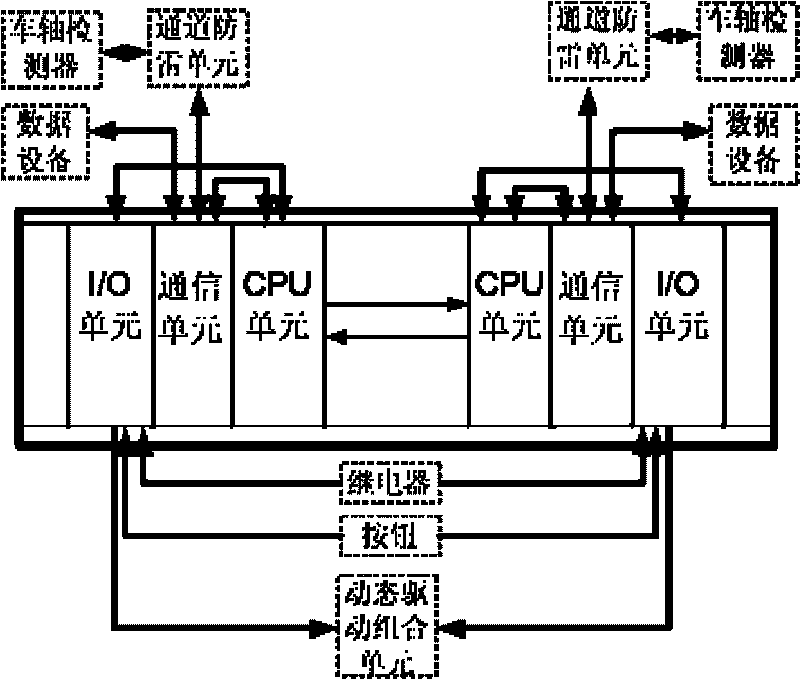

[0048] A gravity induction axle counting device in a station (such as figure 1 shown), including axle detector I located on the line, a set of axle counting information processing system II located indoors, a set of input and output subsystem III, axle counting information processing system and axle detectors located indoors and on the line respectively Data communication subsystem and power supply, power supply lightning protection unit; described axle detector 1 is made up of the sensor unit installed on the waist of line unilateral rail, the wheel electronic detector installed in the equipment box, wherein, each meter A sensor unit is arranged at the axis point, and each sensor unit is a gravity inductive sensor unit composed of 1#, 2#, and 3# gravity inductive sensors; The electronic detector is composed of an axle counting CPU unit, a signal processing unit, a sensor power supply unit and a ...

Embodiment 2

[0066] Embodiment 2: Inter-station gravity induction axle counting equipment

[0067] A gravity induction axle counting device between stations (such as Figure 4 shown), its basic structure is the same as that of Embodiment 1, including an axle detector I located on the line, an indoor axle counting information processing system II, an input and output subsystem III, and an axle counting information processing system located indoors and on the line respectively The difference between the system and the axle detector data communication subsystem, power supply, and power supply lightning protection unit is that the system also includes an inter-station communication transmission subsystem IV, which is mainly composed of a remote communication unit , a communication lightning protection unit and an inter-station communication transmission line, the remote communication unit is connected through the inter-station communication transmission line and the communication lightning pro...

Embodiment 3

[0073] Embodiment 3: A method for detecting section status in a station by using gravity-inductive axle counting equipment in the station

[0074] A method for detecting the state of a section in a station using gravity-inductive axle counting equipment in a station. The method is to install a sensor unit composed of 3 to 7 gravity-inductive sensors on the rail at each axle counting point of the line to sense the gravity of the rail itself under the wheel gravity. The elastic stress changes under the load, and the wheel signal corresponding to the elastic stress change is generated. The wheel signal is transmitted to the signal processing unit of the wheel electronic detector for processing, and then converted into a pulse waveform, which is then transmitted to the Axle counting CPU unit; the axle counting CPU unit of the wheel electronic detector collects and counts the pulse waveform, compares the data information and calculates the train running information, and then sends t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com