Grinding liquid for wire sawing

A technology of grinding liquid and wire saw, which is applied in the field of grinding liquid, can solve the problems of poor quality of GaAs wafers and achieve the effect of simple price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

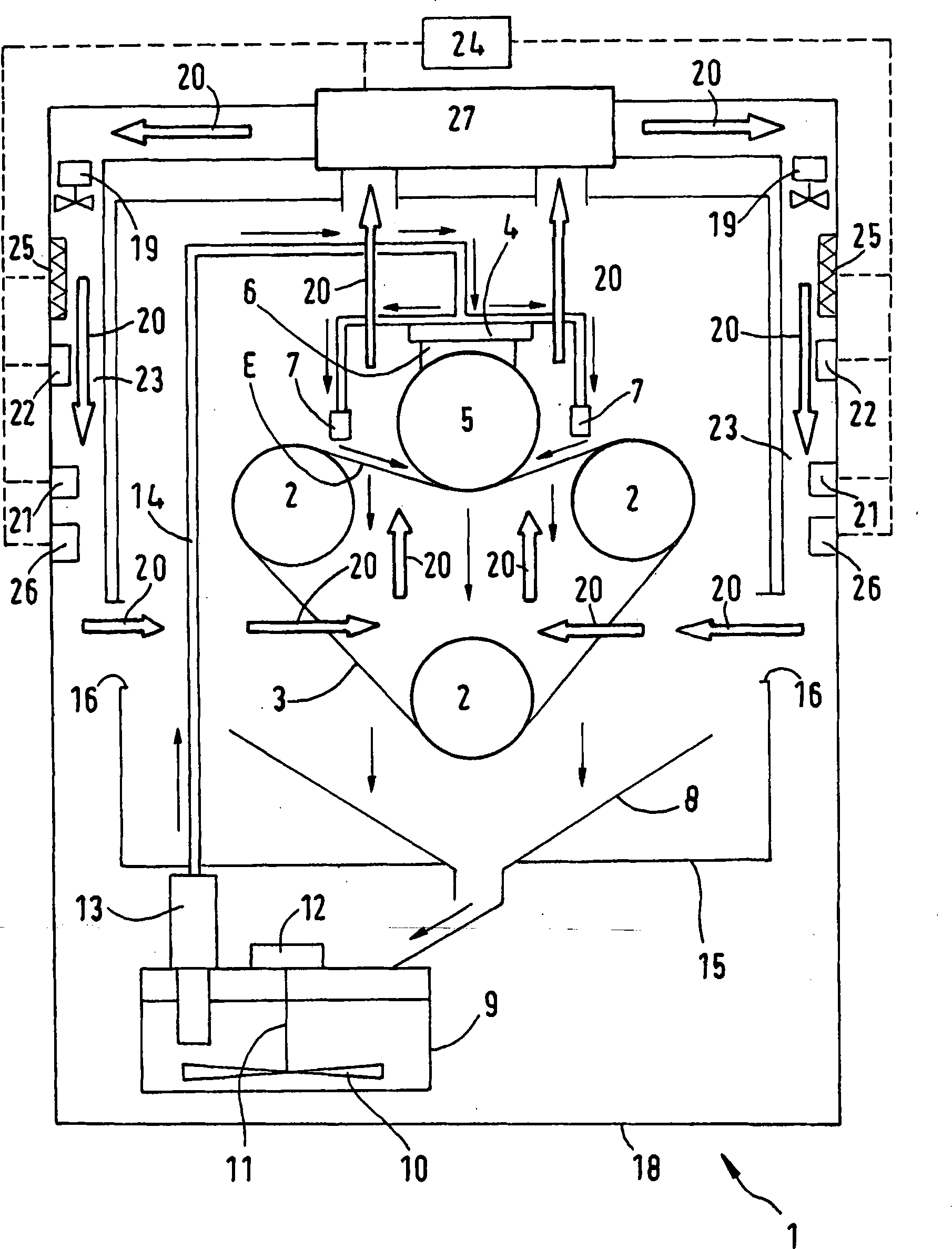

[0038] figure 1 A first exemplary embodiment of a wire saw 1 according to the invention is shown.

[0039] The wire saw 1 has several wire guide rollers 2 arranged parallel to each other, and the wire is guided multiple times around said guide rollers 2 in order to tighten a wire area E comprising several parallel wire segments perpendicular to figure 1 The plane of the paper. A feed device 4 is also provided, on which the workpiece 5 can be fixed with a saw blade 6 . The workpiece 5 fixed thereon can be moved through the wire area E in a direction perpendicular to the wire area E by means of the feed device 4 . The wire guide roller 2 is connected to a rotating device, not shown, which rotates the wire guide roller 2 in order to move the wire along its longitudinal axis.

[0040] Two abrasive liquid nozzles 7 are arranged above the steel wire plane, and the abrasive liquid can be coated on the steel wire area E through the nozzles 7 . In this case, the abrasive liquid noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com