Double-wing type combined trajectory energy dissipation structure

An energy dissipator and double-fin technology, which is applied in the field of flood discharge and energy dissipation facilities, can solve the problems of increasing project investment and construction period, increasing the amount of protection works, and difficulty in returning water to the trough, so as to save project investment and construction period, and reduce construction difficulty. The effect of small, excavation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

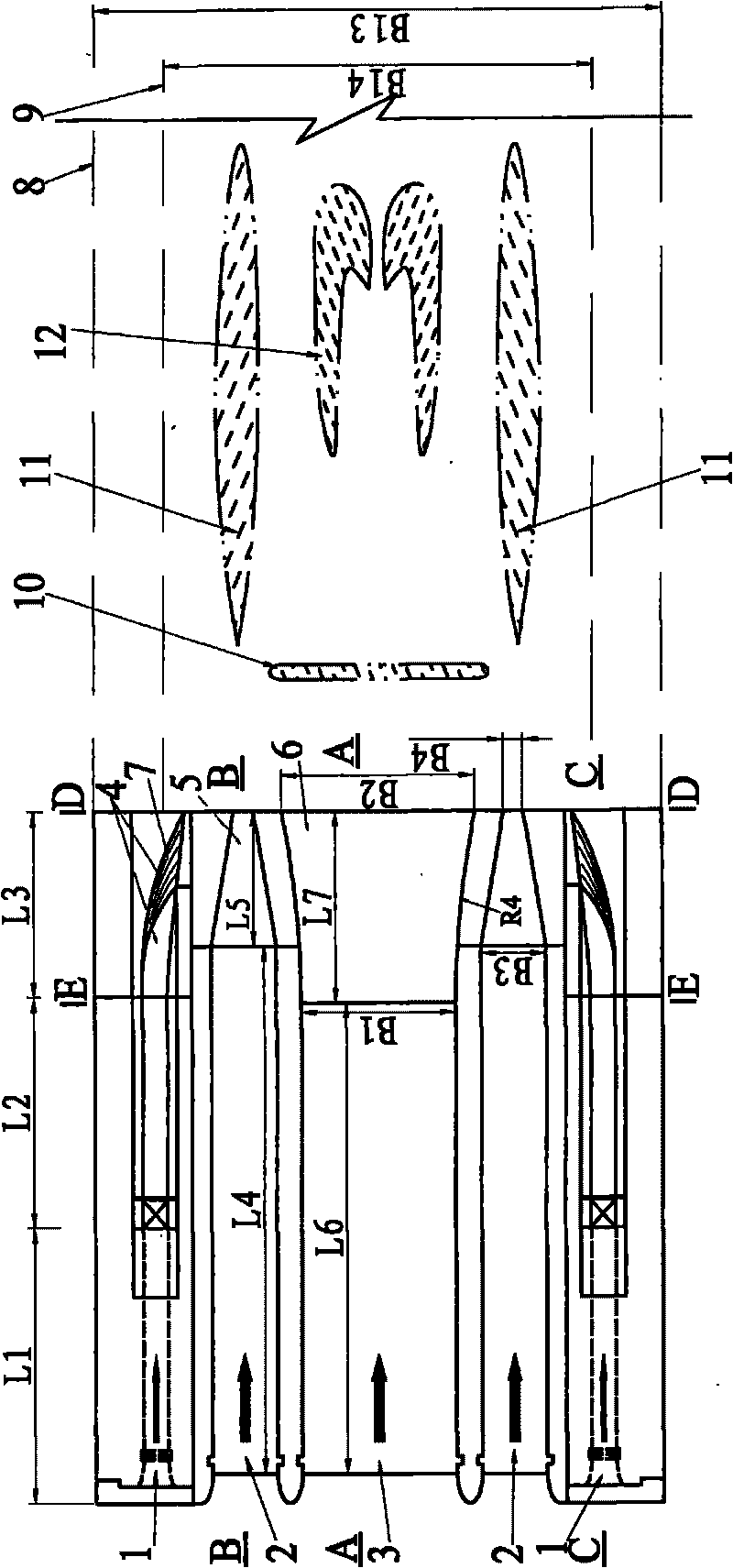

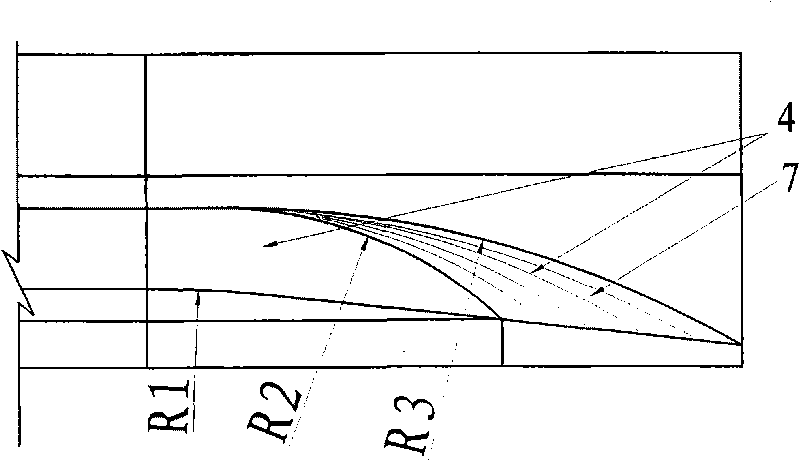

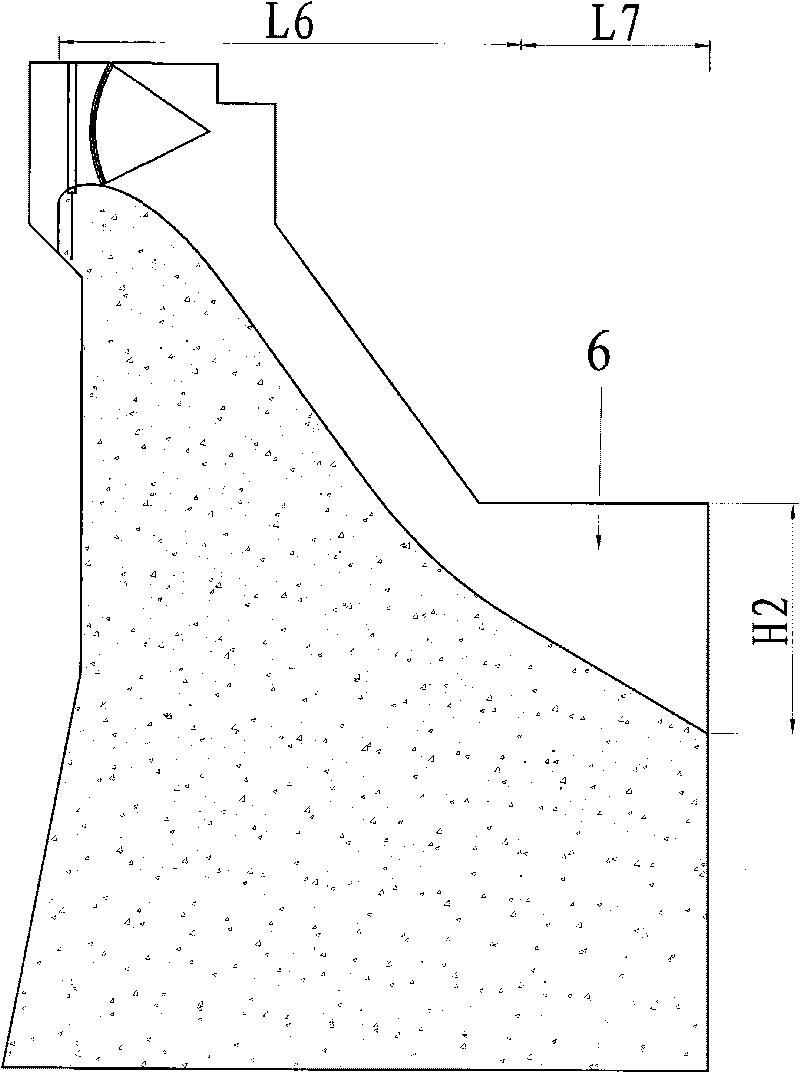

[0021] The structure of the double-fin combined jet energy dissipater of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] The double-wing type combined jet energy dissipater in this embodiment is based on the design of a hydropower station's pivotal project. The power station is located in a narrow river valley section with steep slopes on both banks. The downstream of the hydropower station is connected to a cushion pond. 23 degree corner.

[0023] The structure of the double-fin combined jet energy dissipater in this embodiment is as follows figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, it includes a central overflow groove 3, a structure located on both sides of the central overflow groove, two overflow side grooves of the same size 2, a structure respectively located outside the two overflow side grooves, and two discharge bottom holes 1 of the same size. . The outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com