Lithium-ion secondary battery

A secondary battery and lithium-ion technology, applied in secondary batteries, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of brittle separators, complicated procedures, and complicated processes, so as to inhibit damage and improve safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

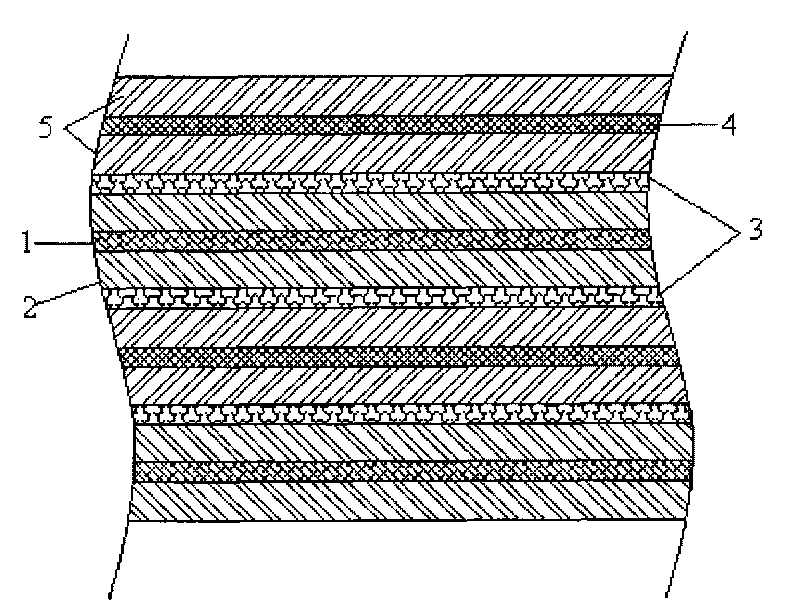

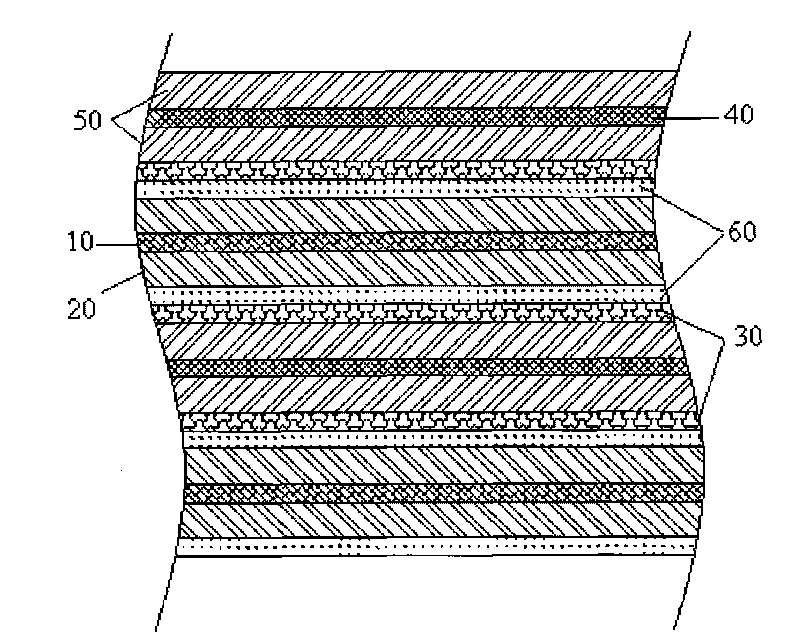

Method used

Image

Examples

Embodiment 1

[0035] Preparation of positive electrode sheet: lithium cobalt oxide (LiCoO 2 ), conductive carbon black (Super-P), polyvinylidene fluoride (PVDF) mixed with N, N-dimethylpyrrolidone (NMP) in a weight ratio of 93:3:4, and stirred evenly to obtain a slurry coated with a positive electrode sheet The viscosity can be adjusted by NMP during the stirring process; then, the slurry coated with the positive electrode sheet is evenly coated on both sides of the 12 μm thick positive electrode current collector (aluminum foil) according to a certain width, and the positive electrode sheet coated with only one side is made at the same time ; Finally, through cold pressing, slicing (that is, cutting the pole piece and cutting it into the required size) to make the positive pole piece.

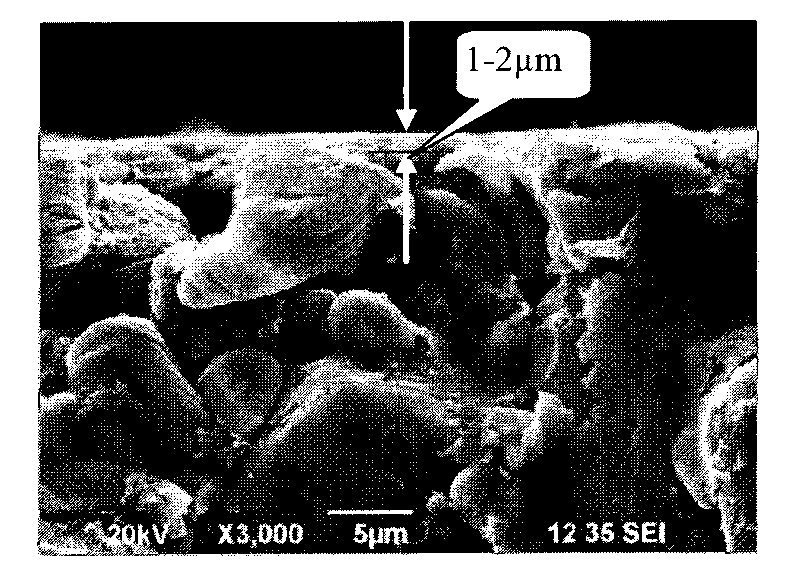

[0036] Preparation of the oxide layer: SiO with a particle size of 20nm 2 Disperse in acetone, add vinylidene fluoride-hexafluoropropylene copolymer (PVDF-HFP) as a binder, spread it through a stirring tan...

Embodiment 2

[0041] Preparation of the positive electrode sheet: lithium cobalt nickel manganese oxide (LiNiCoMnO 2 ), conductive carbon black (Super-P), polyvinylidene fluoride (PVDF) mixed with N, N-dimethylpyrrolidone (NMP) in a weight ratio of 95:2:3, and stirred evenly to obtain a slurry coated with a positive electrode sheet Material, the viscosity can be adjusted by NMP during the stirring process; then, the slurry coated with the positive electrode sheet is evenly coated on both sides of the 12 μm thick positive electrode current collector (aluminum foil) according to a certain width, and the positive electrode sheet coated with only one side is produced at the same time; Finally, cold pressing and slicing (that is, cutting and cutting the pole piece into the required size) are used to prepare the positive pole piece.

[0042] Preparation of the oxide layer: Al with a particle size of about 1 μm 2 o 3 Disperse in acetone, add SBR as a binder, disperse evenly through a stirring ta...

Embodiment 3

[0047] Preparation of the positive electrode sheet: lithium cobalt nickel manganese oxide (LiNiCoMnO 2 ), conductive carbon black (Super-P), polyvinylidene fluoride (PVDF) mixed with N, N-dimethylpyrrolidone (NMP) in a weight ratio of 95:2:3, and stirred evenly to obtain a slurry coated with a positive electrode sheet Material, the viscosity can be adjusted by NMP during the stirring process; then, the slurry coated with the positive electrode sheet is evenly coated on both sides of the 12 μm thick positive electrode current collector (aluminum foil) according to a certain width, and the positive electrode sheet coated with only one side is produced at the same time; Finally, cold pressing and slicing (that is, cutting and cutting the pole piece into the required size) are used to prepare the positive pole piece.

[0048] Preparation of the oxide layer: Sb with a particle size of 200nm 2 o 5 Disperse in water, add acrylic acid (PAA) as a binder, disperse evenly through a sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com