Positive plate reinforced lead-acid accumulator

A technology for lead-acid batteries and positive plates, applied in the direction of lead-acid batteries, lead-acid battery electrodes, etc., can solve the problems of reduced binding force between active material particles, increased porosity, and battery failure, so as to improve service life and prevent The effect of battery failure, delaying the growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

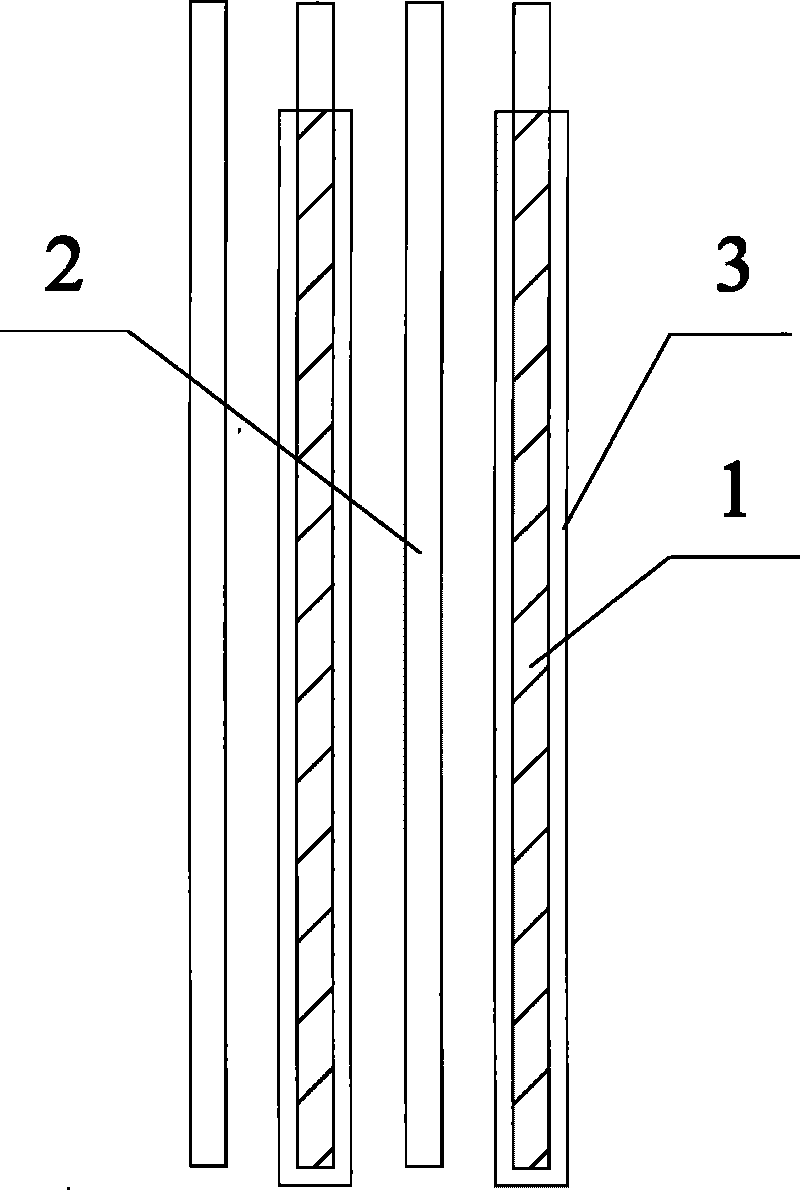

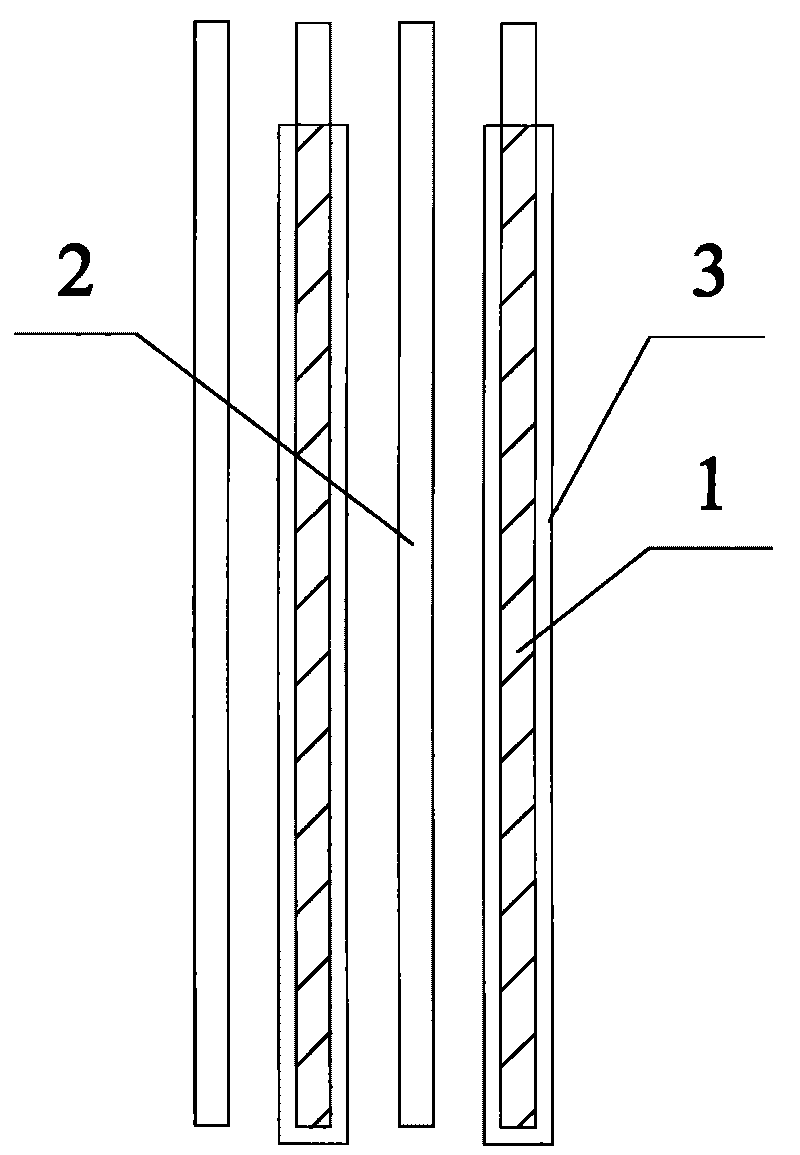

[0028] Example: Combine figure 1As shown, the positive plate-reinforced lead-acid battery provided in this embodiment includes several positive plates 1 and negative plates 2 arranged at intervals, wherein the active material surface of the positive plate 1 is coated with a carbon fiber composite coating 3. The carbon fiber composite coating 3 is made of a mixture of carbon fiber 35%, graphite fiber 35%, carboxymethyl cellulose 12%, and fluororubber 18% by weight to coat the active material on the positive plate 1. The surface is then dried and cured. And in this embodiment, the total weight of the above mixture accounts for 0.002% of the weight of lead in the lead paste formula of the positive plate 1 .

[0029] The carbon fibers and graphite fibers used in this example are commercial carbon fibers and graphite fibers with a strength of 2000 MPa and a modulus of 250 GPa.

[0030] In this embodiment, the drying temperature is preferably 35° C., and the drying time is 1 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com