Anti-fatigue conductive shoes

A conductive shoe, anti-fatigue technology, applied in footwear, soles, clothing and other directions, can solve problems such as inability to use in places with high requirements for fire protection and electrical conductivity, insoles without anti-fatigue function, and shoes without electrical conductivity, etc., to achieve stability. Good performance and strength, good shape function, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

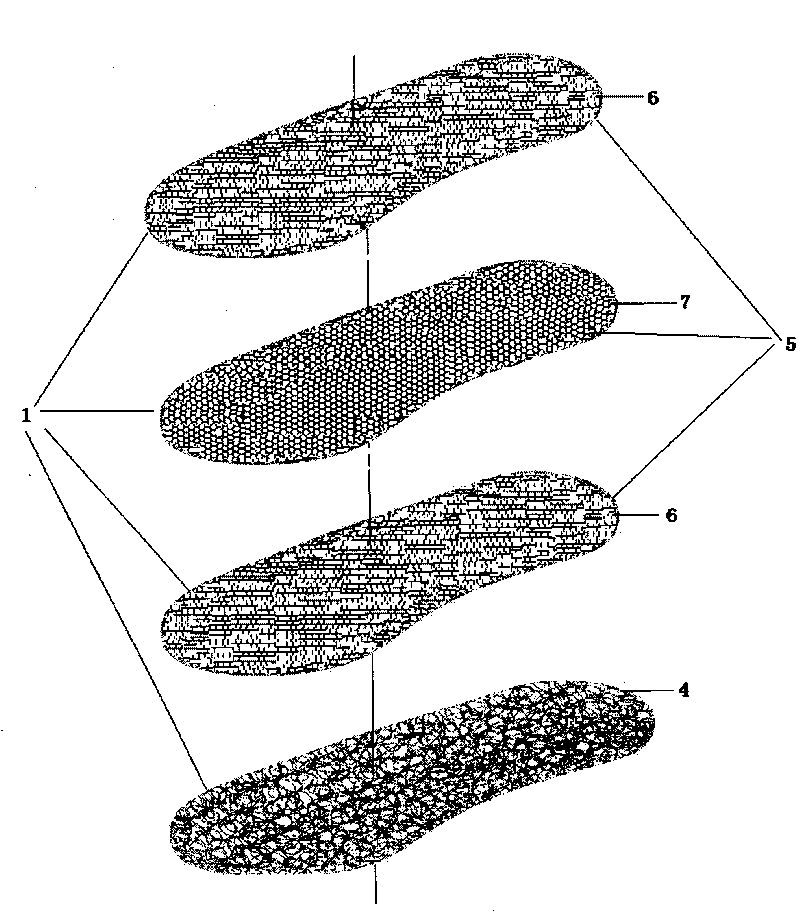

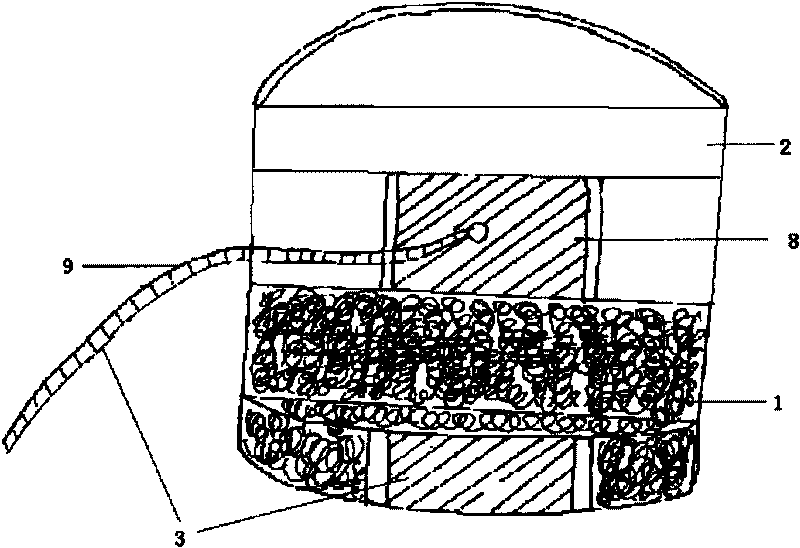

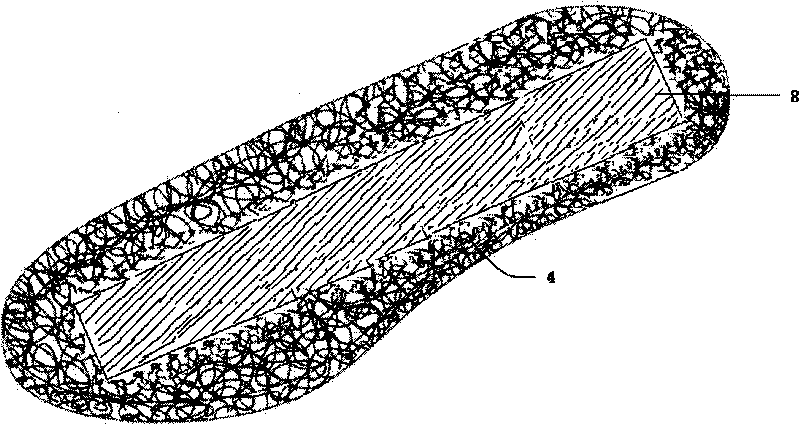

[0020] like Figure 1 to Figure 3 As shown, a kind of anti-fatigue conductive shoe of the present invention, it comprises sole 1, vamp 2, conductive device 3, and described sole 1 comprises undersole 4 and the upper sole 5 that is glued on the undersole 4, The upper layer 5 of the sole is made up of the upper and lower two-layer sandwich net 6 and the ethylene-vinyl acetate copolymer layer 7 glued between the upper and lower two-layer sandwich net 6, and the conductive device 3 is arranged on the lower layer 4 of the sole. The electrostatic guide block 8 and the conductive rope 9 that is arranged on the heel of the vamp 2 and is connected with the electrostatic guide block 8 are formed.

[0021] The lower layer 4 of the sole is made of a thermoplastic wire loop, such as polyvinyl chloride material, which has the advantages of environmental protection and non-toxicity, and good corrosion resistance; because the plastic wire loop has a large pore structure, and the soft and hard...

Embodiment 2

[0025] An anti-fatigue conductive shoe according to the present invention includes a sole 1, a vamp 2, and a conductive device 3. The sole 1 includes an undersole 4 and an upper sole 5 adhered to the undersole 4. The described The upper layer 5 of the sole is composed of the upper and lower two-layer sandwich net 6 and the ethylene-vinyl acetate copolymer layer 7 bonded between the upper and lower two-layer sandwich net 6. Block 8 and the conductive rope 9 that is located on the heel of the vamp 2 and is connected with the electrostatic guide block 8 form.

[0026] The lower layer 4 of the sole is made of a thermoplastic wire loop, such as ethylene-vinyl acetate copolymer material, which has the advantages of environmental protection and non-toxicity, and good corrosion resistance; because the plastic wire loop has a large pore structure, and the wire loop layer The softness and hardness are moderate. When the human body puts pressure on the plastic wire loop, the wire loop wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com