Synthesizing method, partial intermediate products and final products of chiral beta-alkamine derivative

A technology for amino alcohols and a synthetic method is applied in the field of synthesis of chiral beta-amino alcohol derivatives, and can solve the problems of being unsuitable for large-scale production, difficult to obtain raw materials, difficult to control reaction conditions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

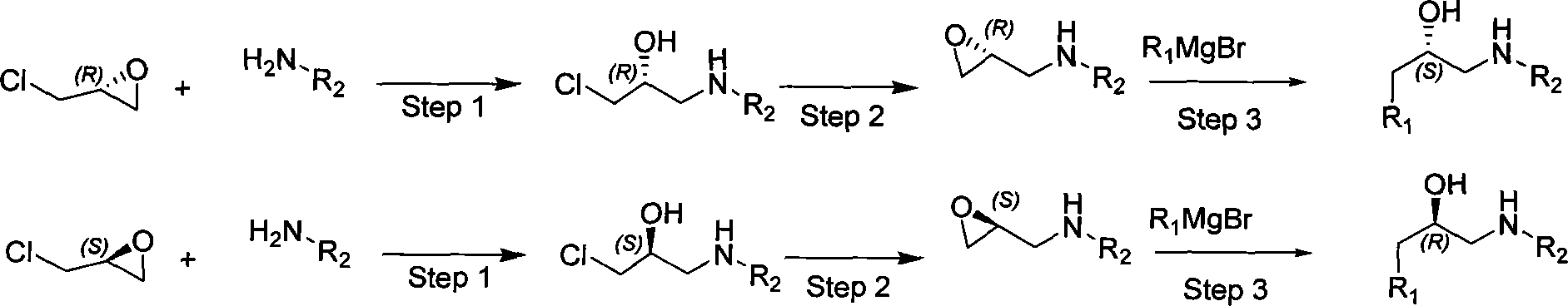

Method used

Image

Examples

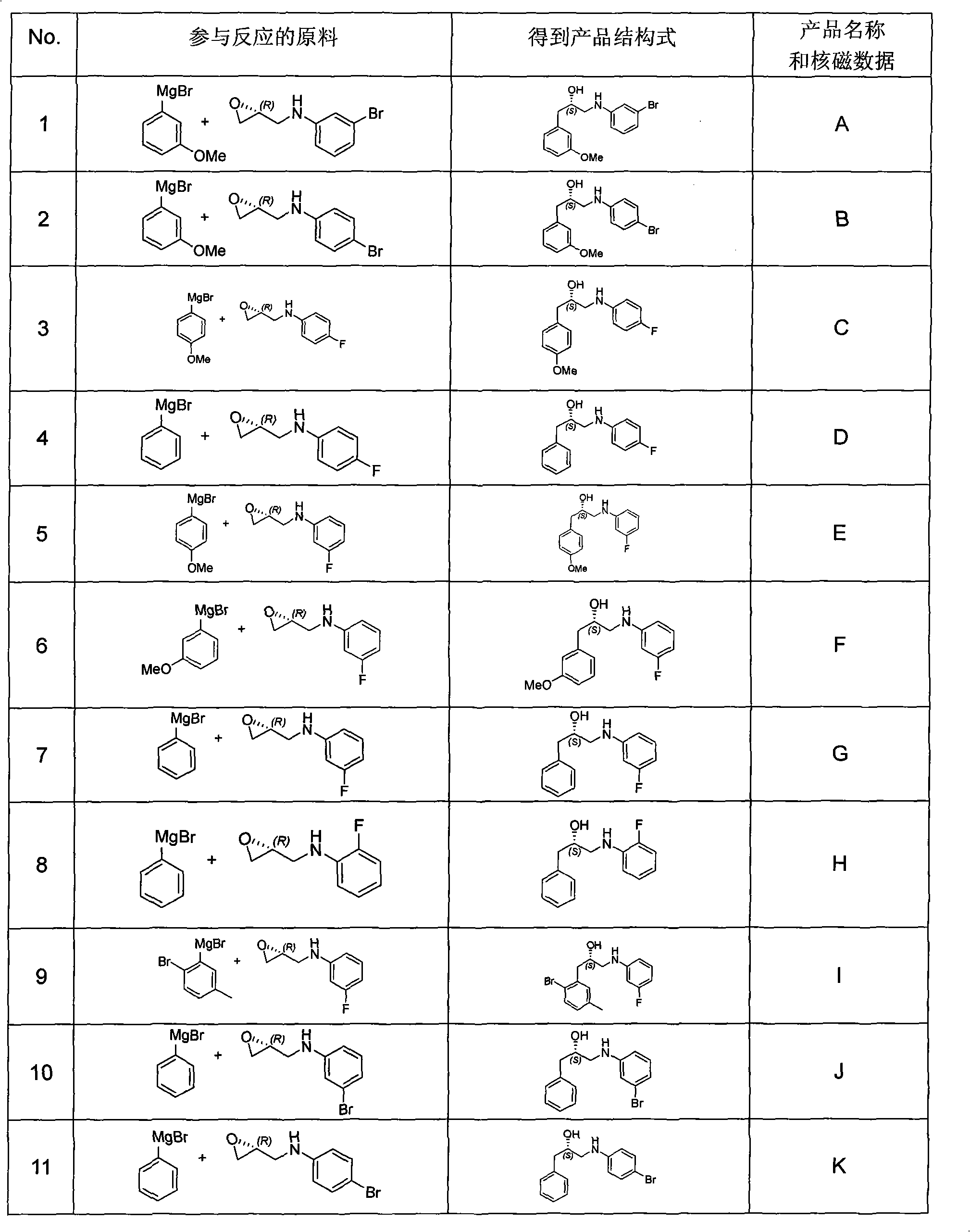

Embodiment 1

[0032] (1) Preparation of R-1-(3-bromoanilino)-3-chloro-propan-2-alcohol,

[0033] Add 100g (R) epichlorohydrin (1eq), 204.6g m-bromoaniline (1.1eq) to a 1L four-necked bottle, add 12.1g stannous chloride dihydrate (SnCl 2 .2H 2 O) (0.05eq), the addition is complete, stirred at 25±1°C, followed by GC until the end of the reaction, 400mL of water was added to terminate the reaction, the system was extracted with 600mL of methyl tert-butyl ether, the organic phase was washed with 150mL of saturated brine, and the The organic phase was dried to obtain 185.9 g of the product, the yield was 65%, the enantiomeric purity (ee): 99.8%, and the gas phase purity (GC): 94%.

[0034] H-NMR: (300MHz, DMSO-d 6 ), δ2.991-3.058 (dd, CH2NH, 1H), δ3.138-3.198 (dd, CH2NH, 1H), δ3.553-3.608 (dd, CH2Cl, 1H), δ3.648-3.699 (dd, CH2Cl , 1H), δ3.800-3.836(m, CH, 1H), δ5.390(b, NH, 1H), δ5.971(b, OH, 1H), δ6.587(d, Ph-H, 1H ), δ6.615 (d, Ph-H, 1H), δ6.772 (s, Ph-H, 1H), δ6.995 (t, Ph-H, 1H).

[0...

Embodiment 2

[0042] (1) Preparation of R-1-(4-fluoroanilino)-3-chloro-propan-2-alcohol,

[0043] Add 150g (R) epichlorohydrin (1eq), 189g p-fluoroaniline (1.05eq) to a 1L four-necked bottle, add 21.9g stannous chloride dihydrate (SnCl 2 .2H 2 O) (0.06eq), the addition is complete, stirred at 26±1°C, followed by GC until the end of the reaction, 400mL of water was added to terminate the reaction, the system was extracted with 800mL of methyl tert-butyl ether, the organic phase was washed with 200mL of saturated brine, and the Dry the organic phase to obtain 358g of crude product, methyl tert-butyl ether:petroleum ether=1:3 recrystallization, obtain product 210g, yield 63.6%, enantiomeric purity (ee): 99.6%, gas phase purity (GC): 96%.

[0044] H-NMR: (300MHz, DMSO-d 6), δ3.032-3.075 (dd, CH2NH, 1H), δ3.158-3.218 (dd, CH2NH, 1H), δ3.576-3.630 (dd, CH2Cl, 1H), δ3.670-3.719 (dd, CH2Cl , 1H), δ3.810-3.846(m, CH, 1H), δ5.503(b, NH, 1H), δ5.998(b, OH, 1H), δ6.501(m, Ph-H, 2H ), δ6.790 (m, ...

Embodiment 3

[0053] (1) Preparation of R-1-(4-bromoanilino)-3-chloro-propan-2-alcohol,

[0054] Add 50g (R) epichlorohydrin and 106.9g 4-bromoaniline (1.15eq) into a 500mL four-necked bottle, add 7.05g lithium bromide (0.15eq) to the system in two batches, after the addition is complete, stir at 27±1°C, GC tracking to the end of the reaction, 300mL of water was added to terminate the reaction, the system was extracted with 600mL of methyl tert-butyl ether, the organic phase was washed with 150mL of saturated brine, and the organic phase was dried to obtain 71g of the product with a yield of 50%. Enantiomer Purity (ee): 99.7%, gas phase purity (GC): 95%.

[0055] H-NMR: (300MHz, DMSO-d 6 ), δ2.701-3.078 (dd, CH2NH, 1H), δ3.158-3.218 (dd, CH2NH, 1H), δ3.532-3.587 (dd, CH2Cl, 1H), δ3.627-3.678 (dd, CH2Cl , 1H), δ3.806-3.847(m, CH, 1H), δ5.270(b, NH, 1H), δ5.983(b, OH, 1H), δ6.560(d, Ph-H, 1H ), δ6.651 (d, Ph-H, 1H), δ6.790 (d, Ph-H, 1H), δ6.974 (d, Ph-H, 1H).

[0056] (2) Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com