Method for producing dehydroepiandros-sterone

A technology of dehydroepiandrosterone and production steps, which is applied in the field of production of dehydroepiandrosterone, can solve the problems of long production cycle, polluted environment by waste liquid, and high cost of dehydroepiandrosterone, and achieves the effect of reducing the usage amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

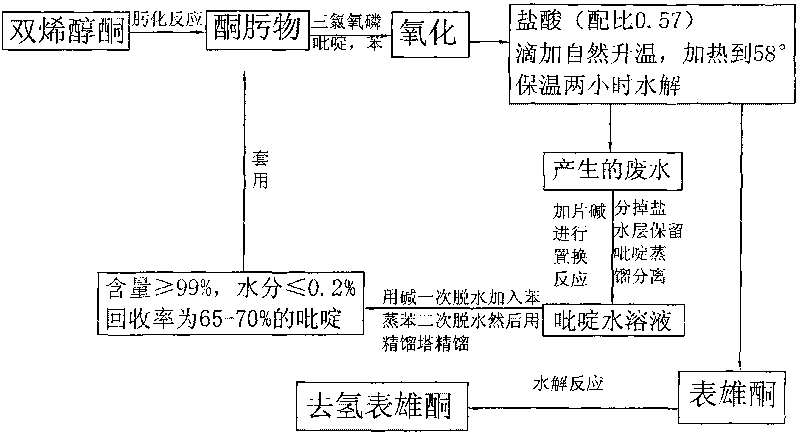

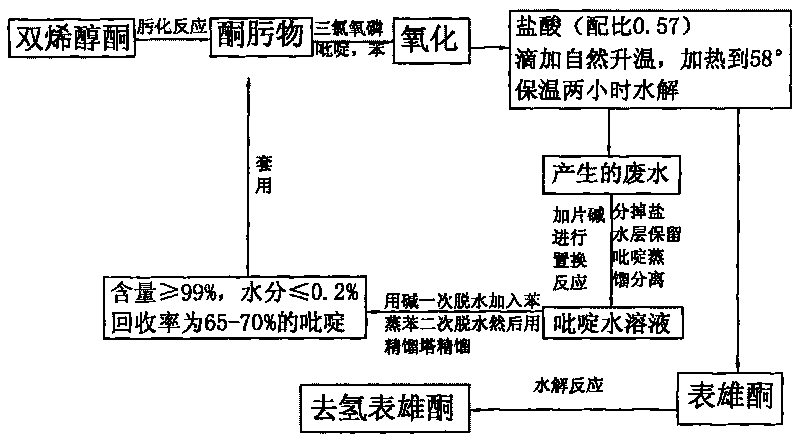

[0017] like figure 1 as shown,

[0018] First, in the reaction tank, 120kg of ketoximes obtained by the oximation reaction of dienes, dried with a water content of ≤0.5%, were added to 780kg of benzene dehydrated by edible salt, and heated and dissolved. After the ketoximes were completely dissolved, the temperature was lowered to 38 ℃±2℃, then add 57.6kg of pyridine, the content of pyridine is ≥98%, and the water content is less than 0.2%;

[0019] Next, in the jacket of the reaction tank, pass salt water to lower the temperature by 5-8°C, add dropwise a mixed solution of 58kg phosphorus oxychloride and 98kg benzene, the content of phosphorus oxychloride is ≥ 98%, and the dropwise temperature is controlled within 15°C. After adding the mixed solution of phosphorus oxychloride and benzene dropwise, keep the reaction at 16°C-18°C;

[0020] Next, quickly add 227kg of dilute hydrogen chloride acid water to the solution after reacting for 3 hours, the content of hydrogen chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com