Bio-based compatilizer, preparation method and application thereof

A compatibilizer and bio-based technology, which is applied in the field of bio-based compatibilizer preparation, can solve problems such as the influence of hydrogen bond force by ambient temperature, easy migration or precipitation of phenolic compounds, and difficulty in controlling the degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

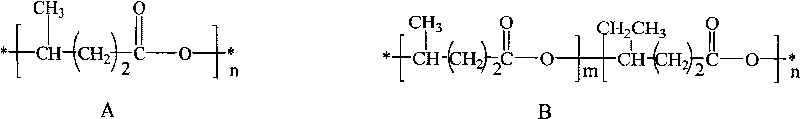

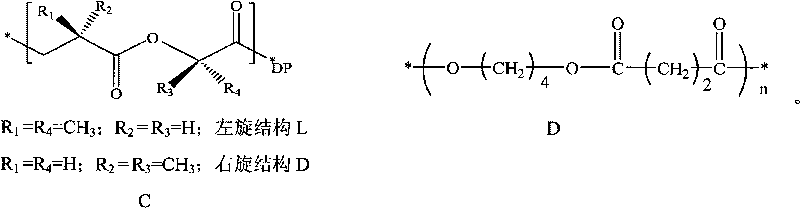

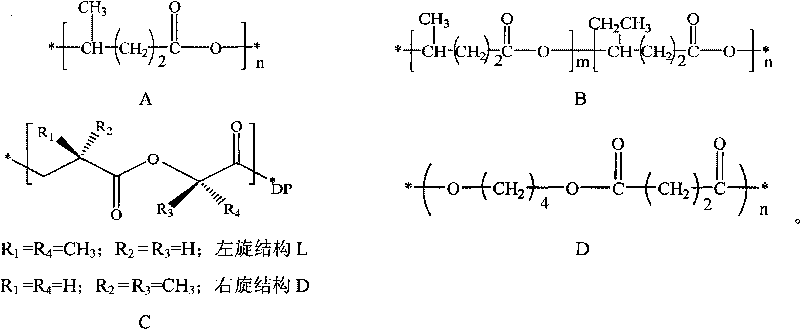

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1: the alcohol depolymerization of PHB

[0083] Weigh 50.0-1000.0g PHB resin (weight average molecular weight: 90,000), 0.5-8.0g p-toluenesulfonic acid, measure 0.5-5L ethylene glycol, pour the above materials into a three-necked flask or a reaction kettle, and nitrogen Protect. Heating in an oil bath with the temperature controlled at 170°C, stirring and reacting for 10 to 70 minutes, cooling at room temperature, and then using a sand core funnel to suction filter the degradation product (the filtrate can be recycled and reused), rinse with cold absolute ethanol several times, and put Vacuum-dry in a vacuum oven at 60°C for 6 hours to obtain white granular products with different molecular weights. Then take PHB with different weight average molecular weights (50,000, 80,000 and 140,000) to repeat the above test, and obtain the data in Table 1 below.

[0084] Table 1 The weight-average molecular weight (Mw) of phb in different reaction times

[0085]

Embodiment 2

[0086] Example 2: Alcohol depolymerization of PHBV

[0087] Weigh 50.0-1000.0g PHBV resin (weight average molecular weight is 120,000, HV% is 5%), 0.5-6.0g p-toluenesulfonic acid, measure 0.5-5L ethanol, pour the above materials into a three-necked flask or a reaction kettle , Nitrogen protection throughout the reaction. Heating in an oil bath with the temperature controlled at 175°C, stirring and reacting for 10 to 70 minutes, then cooling at room temperature, and then using a sand core funnel to suction filter the degradation product (the filtrate can be recycled and reused), rinse it with cold absolute ethanol several times, and put Vacuum-dry in a vacuum oven at 60°C for 6 hours to obtain white granular products with different molecular weights. Then take PHBV with different weight-average molecular weights (60,000, 90,000 and 150,000, HV% are 12%, 20% and 8% respectively) to repeat the above test, and obtain the following data in Table 2.

[0088] The weight-average mol...

Embodiment 3

[0090] Embodiment 3: the alcohol depolymerization of PLA

[0091]Weigh 50.0-1000.0g PLA resin (weight average molecular weight is 40,000, L% is 45%), 1.2-8.0g p-toluenesulfonic acid, measure 0.5-5L isopropanol, pour the above materials into a three-necked flask or react In the kettle, nitrogen protection was used throughout the reaction. Heating in an oil bath with the temperature controlled at 190°C, stirring and reacting for 10 to 70 minutes, cooling at room temperature, and then suction filtering the degradation product with a sand core funnel (the filtrate can be recycled and reused), rinsed several times with cold absolute ethanol, and put Vacuum-dry in a vacuum oven at 60°C for 6 hours to obtain white granular products with different molecular weights. Then take PLA with different weight-average molecular weights (60,000, 80,000 and 90,000, and the L% is 98%, 30% and 66% respectively) and repeat the above test to obtain the data in Table 3 below.

[0092] The weight-av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com