Method for comprehensively recovering indium and gallium from distilled waste acid containing indium and gallium

A technology of indium gallium and hydrochloric acid, which is applied in photography technology, equipment, photography auxiliary technology, etc., and can solve problems such as waste of valuable metals and pollution of the factory environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below through specific examples.

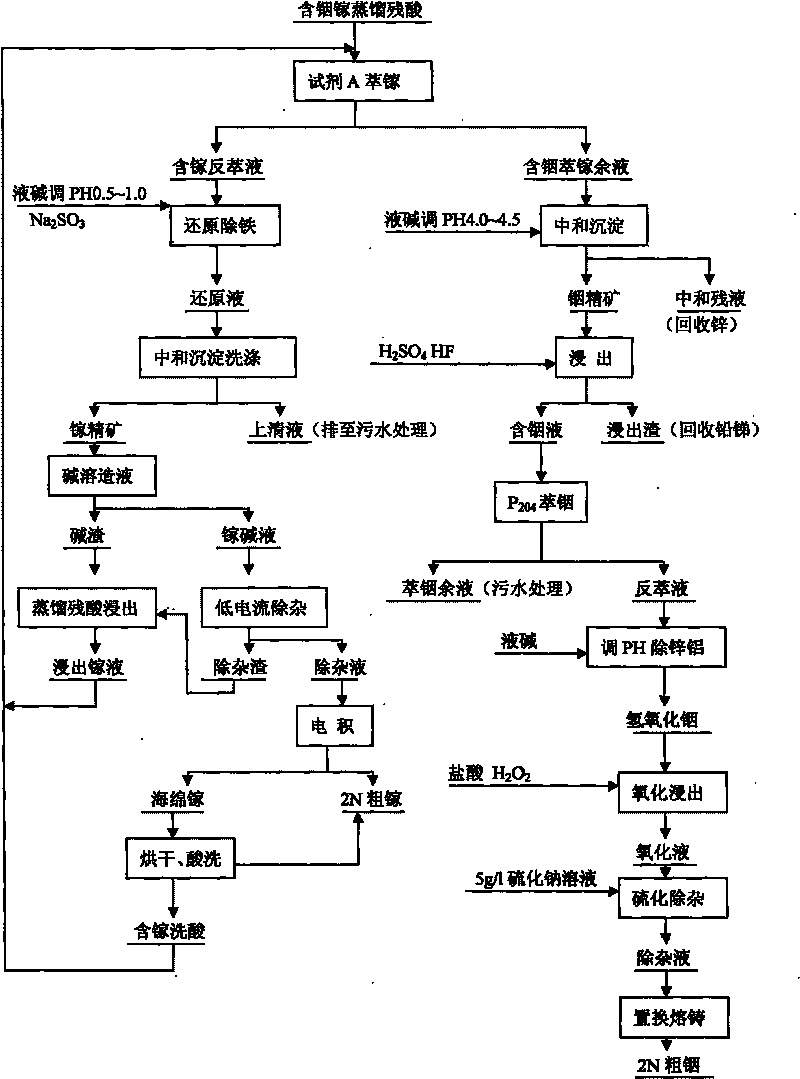

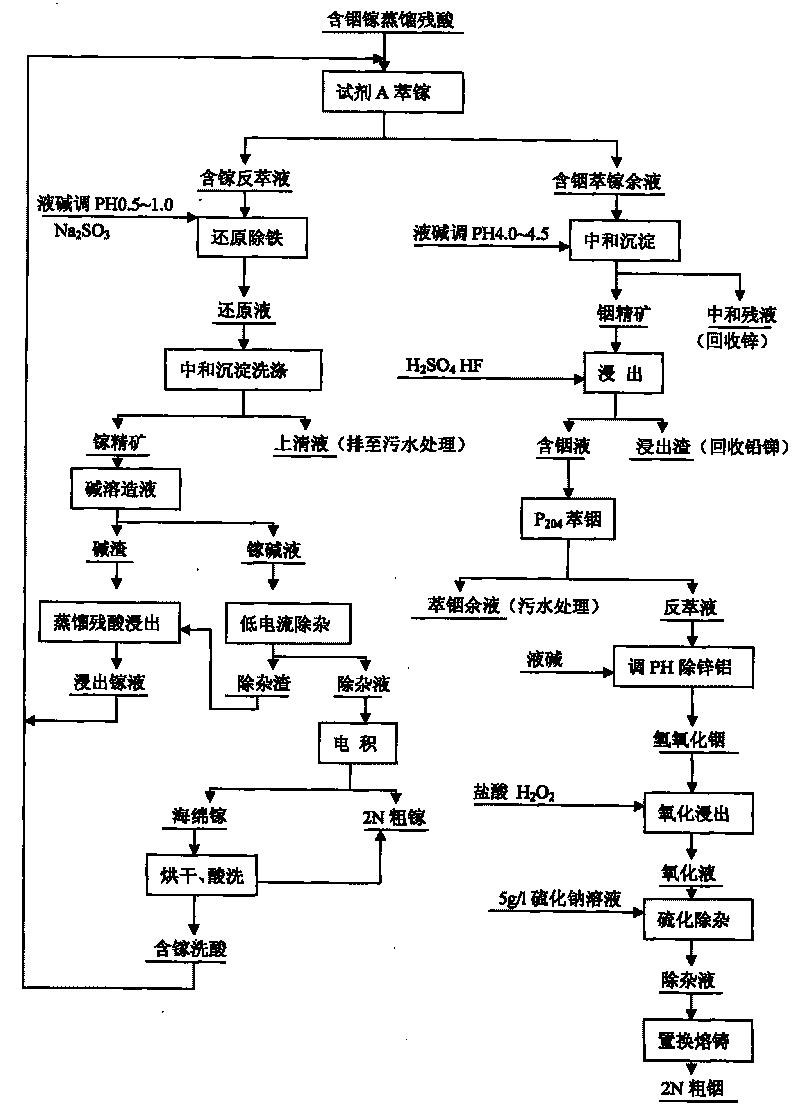

[0023] Such as figure 1 As shown, it is a process flow chart of recovering indium gallium from distillation raffinate according to an embodiment of the present invention.

[0024] 1. Recovery of Ga in distillation raffinate

[0025] Considering that the acidity of distillation waste acid is generally >7-8N, the extraction reagent with good extraction performance in high acidity solution is the first choice. Gallium is extracted and recovered from hydrochloric acid solution, and ethyl acetate is selected as a reagent with better separation performance between primary and heterometallic metals.

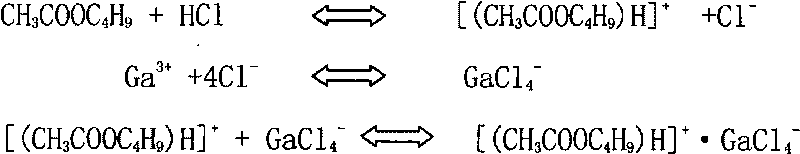

[0026] 1.1 Extraction mechanism

[0027] In the highly acidic hydrochloric acid solution, the oxygen atoms in the extractant release lone pairs of electrons, protonate to form cations, and Ga generates complex anions GaCl 4 - , the two are exchanged and ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com