Bridge bearing platform composite material collision post

A technology of composite materials and fiber composite materials, which is applied in the field of anti-collision columns made of composite materials for bridge caps, can solve the problems of easy damage to the hull, high cost of steel casings, and high maintenance costs, and achieve easy maintenance and repair, convenient construction, and Reliable effect of anti-collision function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

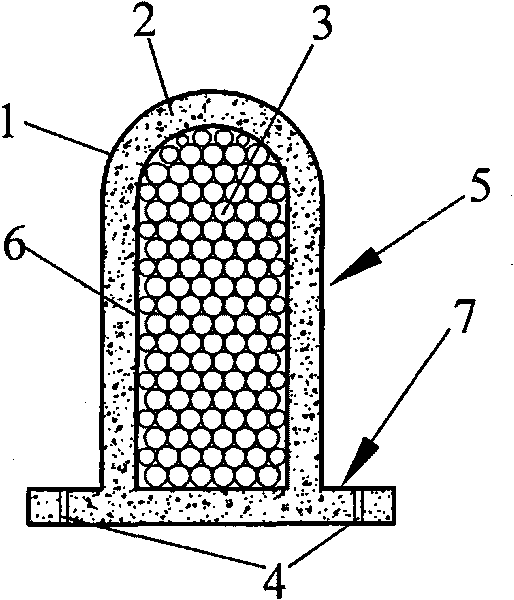

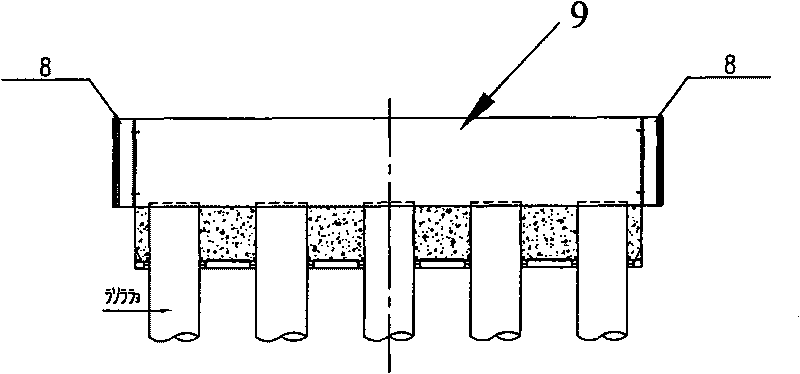

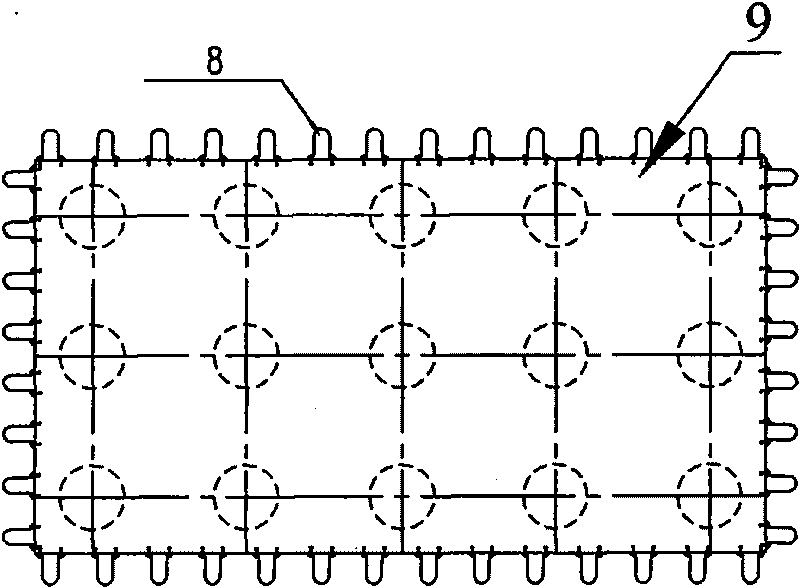

[0032] In the composite material bridge anti-collision column of the present invention, the shell is a composite material surface layer 1 formed by curing glass fiber and vinyl resin, and adopts Paulownia wood core material 2 to form a composite material sandwich structure shell, and the cross section of the shell is semicircular D-shaped. Prepared by vacuum introduction process, using flanges and bolts 4 to combine the D-shaped shell and the flat shell to form a closed composite shell; the interior of the composite shell is filled with moso bamboo 3 arranged horizontally; the anti-collision columns are spaced at a certain distance around the rectangular cross-section pier fixed.

example 2

[0034] The composite material bridge anti-collision column of the present invention, the outer shell is a composite material surface layer 1 cured by basalt fiber and epoxy resin, which constitutes a composite material laminate shell, the cross section of the shell is box-shaped, and chamfering is provided, and a vacuum introduction process is adopted For preparation, use flanges and bolts 4 to combine the box-shaped shell and the flat shell to form a closed composite shell; the interior of the composite shell is filled with polyurethane foam 3, and the anti-collision column is fixed on the shore of the dock.

example 3

[0036] The composite material bridge anti-collision column of the present invention, the shell is a composite material surface layer 1 formed by curing glass fiber and unsaturated polyester resin, and adopts Paulownia wood core material 2 to form a composite material sandwich structure shell; the interior of the composite material shell is filled and recycled The rubber particles 3 constitute the anti-collision column, and the anti-collision column is fixed around the offshore oil production platform.

[0037] The manufacture method of composite bridge anti-collision column of the present invention is as follows:

[0038] a. First prepare a set of large-scale wood or fiberglass molds, and adopt a vacuum introduction process on the mold to prepare the glass fiber / vinyl resin 1 composite anti-collision system shell 5 with Paulownia wood as the sandwich material 2;

[0039] b. Arranging moso bamboo 3 closely and horizontally inside the composite material shell 5, and filling the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com