Composite material tower and manufacturing process thereof

A composite material and tower technology, applied in the field of insulating composite material towers and insulating support components, can solve the problems of poor anti-ultraviolet ability, no insulation effect of power towers, and high cost of carbon fiber, so as to improve the anti-ultraviolet ability and improve the overall insulation level , not easy to aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0028] A composite material pole tower disclosed by the present invention can be applied to various products such as street light poles, traffic light poles, electronic monitoring poles, whole towers, tower heads, tower poles and crossarms of power transmission and distribution power systems. In this embodiment, the The pole tower is illustrated as an example, but the present invention is not limited thereto, and the scope of protection of the present invention is subject to the scope of protection of the claims.

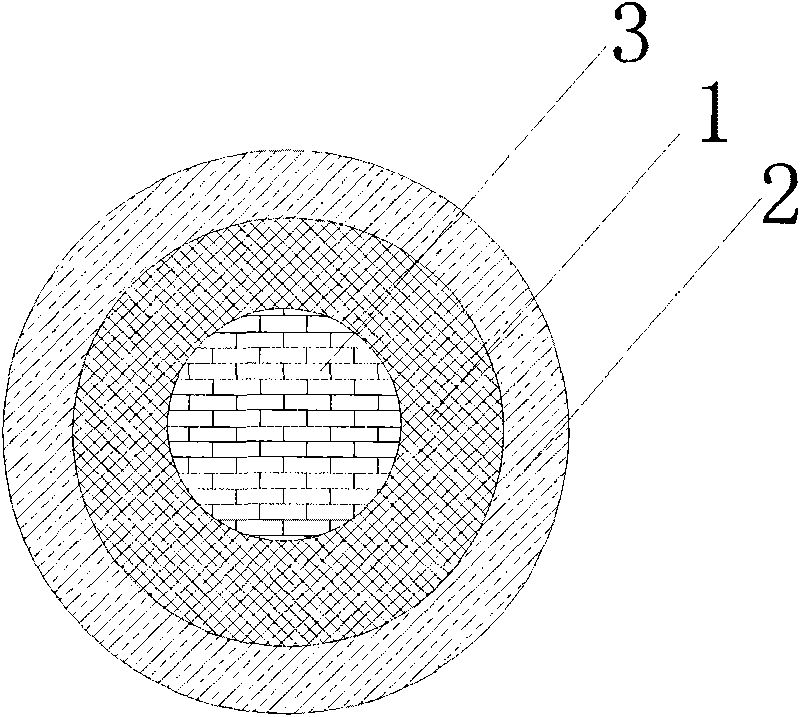

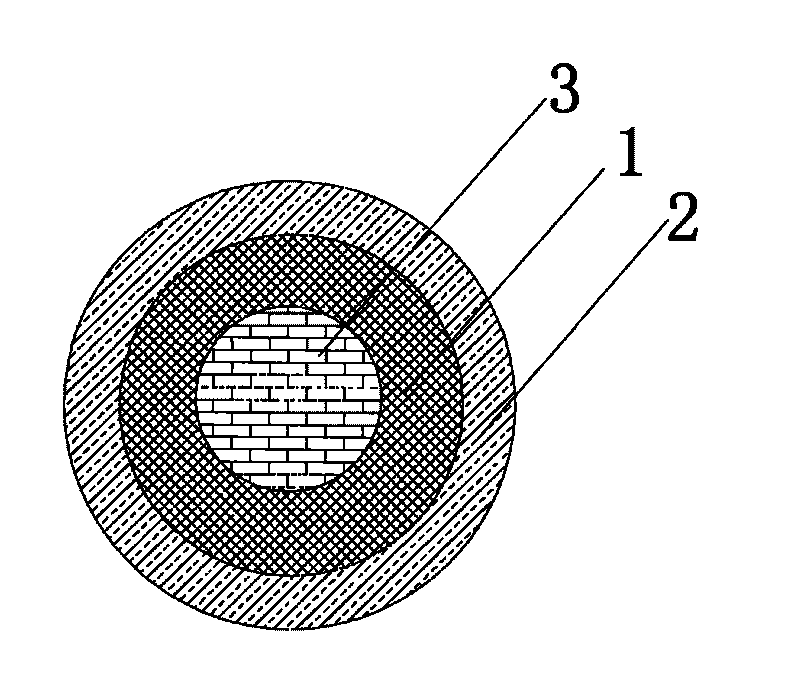

[0029] Such as figure 1 As shown, the cross-section of the composite pole tower in this embodiment is circular, but the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com