Method for manufacturing oxide layer capable of reducing gradient of side wall

A manufacturing method and oxide layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting device performance, etc., achieve the effect of increasing the etching speed and reducing the slope of the side wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

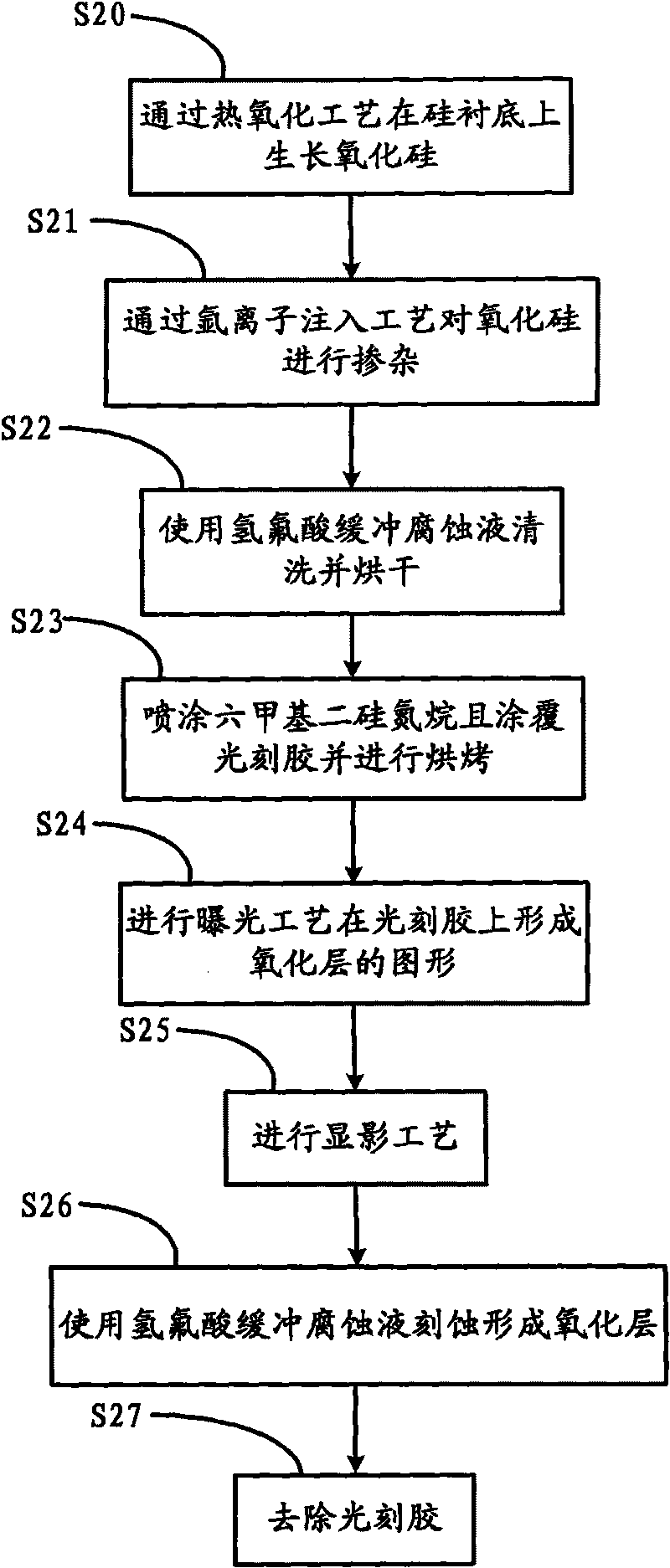

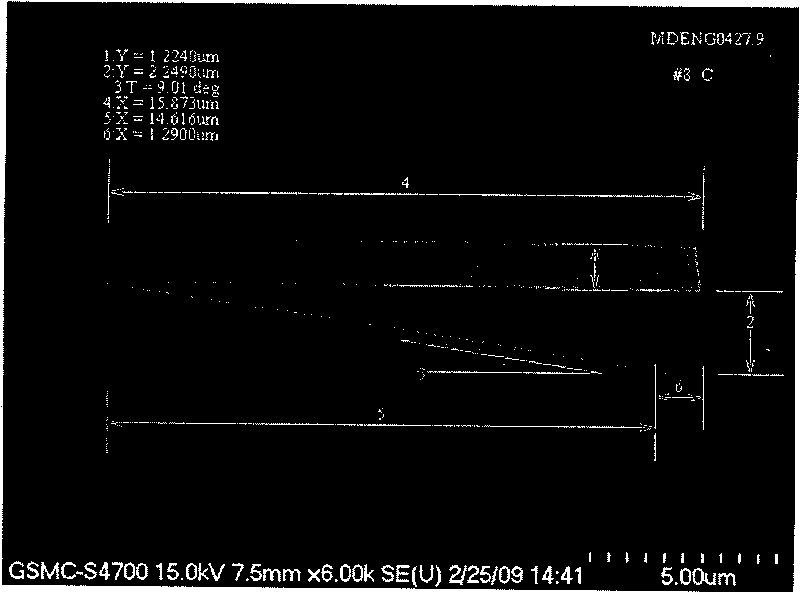

[0022] The oxide layer manufacturing method capable of reducing the slope of the sidewall of the present invention will be further described in detail below.

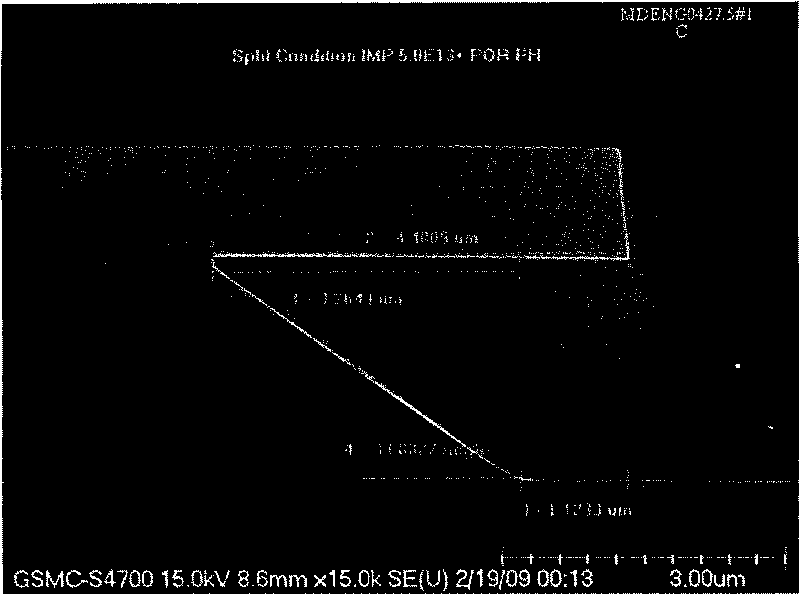

[0023] see figure 2 , which shows the process flow of the oxide layer manufacturing method capable of reducing the slope of the sidewall of the present invention, as shown in the figure, the method of manufacturing the oxide layer capable of reducing the slope of the sidewall of the present invention firstly performs step S20, through the thermal oxidation process in Silicon oxide is grown on the silicon substrate, and the oxidation temperature of the thermal oxidation process is 900 to 1000 degrees Celsius.

[0024] In this embodiment, the oxide layer is a field oxide layer, and its thickness ranges from 2 to 3 microns.

[0025] Then continue to step S21, doping silicon oxide by argon ion implantation process. In this embodiment, the implantation energy of the argon ion implantation process is 80keV, and the dose is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com