Method and device for detecting position of rotor of brushless motor

A rotor position, brushless motor technology, applied in the direction of electronic commutator, etc., can solve the problems of no fault tolerance function, brushless motor rotor position detection method is difficult to meet, reliability is difficult to guarantee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0045] Implementation example of the device of the present invention:

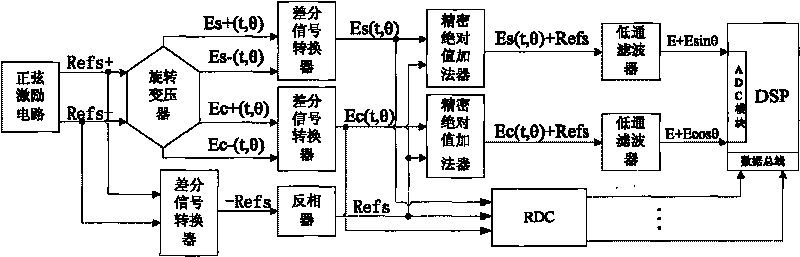

[0046] The detection device is divided into two parts: a resolver installed coaxially with the rotor of the brushless motor under test and a resolver signal conditioning circuit. The resolver signal conditioning circuit includes a sinusoidal excitation circuit as a resolver signal source and self-monitoring and fault-tolerant algorithm signal conditioning. circuit (contains differential signal converter, precision absolute value adder, inverter, and low-pass filter).

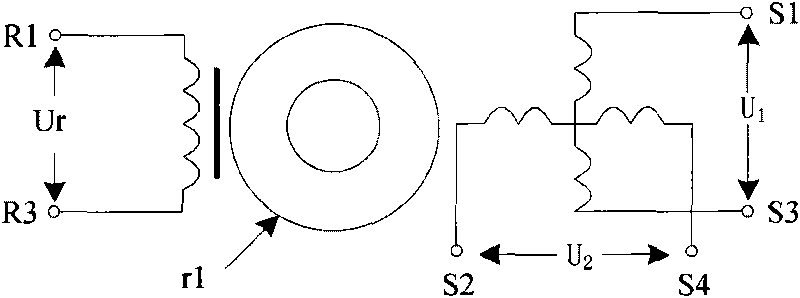

[0047] Schematic diagram of the rotary transformer figure 2 As shown, the resolver rotor r1 is installed coaxially with the motor rotor, Ur is the input end of the excitation signal, U1 and U2 are the output ends of the sine signal and cosine signal respectively.

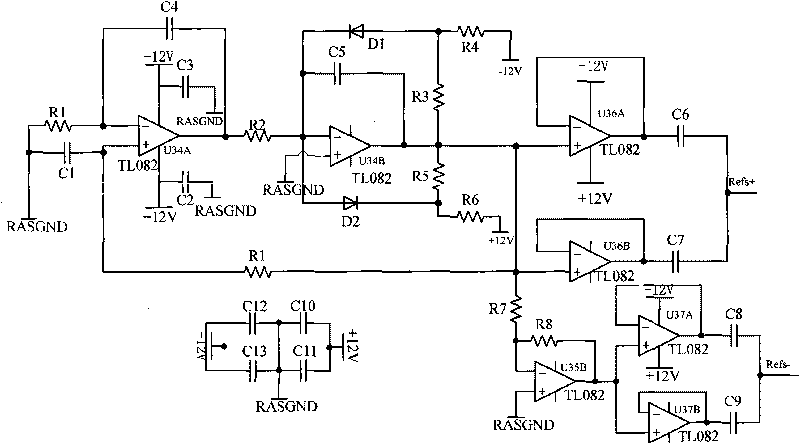

[0048] The sinusoidal excitation circuit uses a modified Wie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com