Method and device for transmitting data between main board and spray nozzle panel of ink-jet printer

A technology of inkjet printers and transmission devices, applied in printing devices, printing, etc., can solve the problems of easy breakage of optical fiber transmission lines, poor electromagnetic compatibility, and slow transmission speed, and achieve good compatibility, fast transmission speed, and fewer transmission lines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

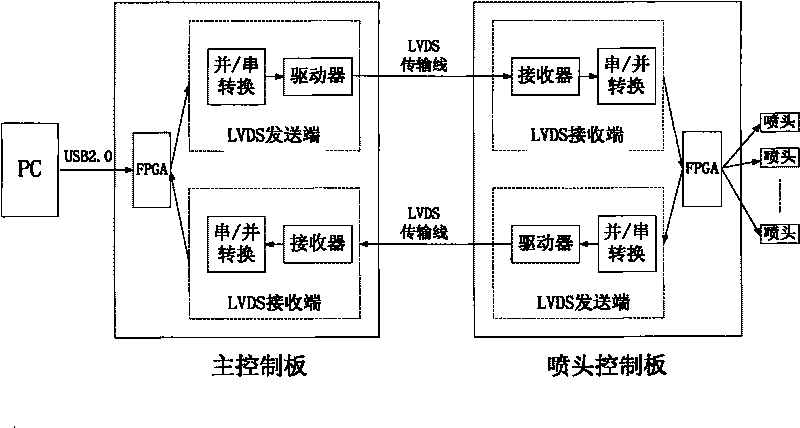

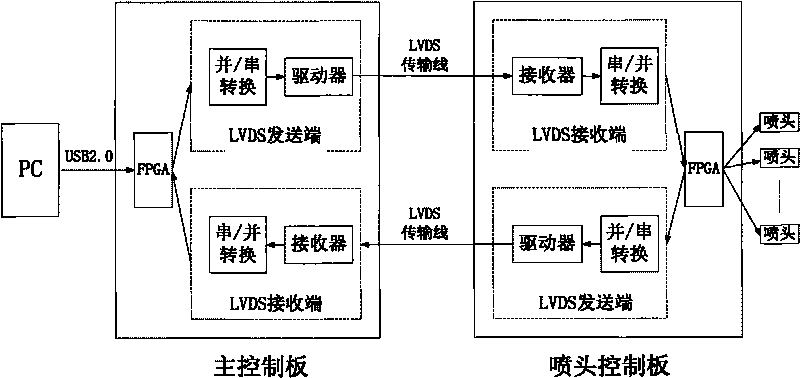

[0016] The data transmission device between the inkjet printer main board and the nozzle board of the present invention includes an LVDS differential transmission control unit and an LVDS transmission line. The LVDS differential transmission control unit includes an FPGA control unit and an LVDS differential transmission drive unit, and the FPGA control unit is a conventional FPGA. Or CPLD and equipped with an interface circuit are respectively set on the main control board of the inkjet printer and the nozzle control board; the LVDS differential transmission drive unit is mainly composed of an LVDS differential transmission driver chip, which is also respectively set on the main control board of the printer and the nozzle control board; The LVDS transmission line is used for data transmission between the main control board and the sprinkler control board. The LVDS differential transmission control unit composed of the LVDS differential transmission driver chip and the FPGA con...

Embodiment 2

[0018] As shown in the figure, the specific steps of the data transmission method between the inkjet printer main board and the nozzle board of the present invention are as follows: when sending data, the PC transmits the data to the buffer memory of the FPGA of the main control board through the USB interface, and the FPGA will The processed data is sent to the LVDS sending module SN65LVDS93 on the main control board of the printer. The LVDS sending module SN65LVDS93 includes a parallel / serial conversion module and a driver, and the TTL signal such as printing data passes through the parallel / serial conversion module to realize the process of parallel to serial conversion , and then form a LVDS differential signal through the driver, and transmit it to the LVDS receiving module SN65LVDS94 on the print head control board through a 20-core shielded twisted pair cable. The LVDS receiving module SN65LVDS94 includes a receiver and a serial / parallel conversion module. The receiver wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com