Preparation method of Co-covered nickel hydroxide anode material with surface covered by rare earth compound

A technology of rare earth compounds and rare earth hydroxides, applied in the field of materials, can solve the problems of thick coating layer detachment, insufficient high temperature characteristics, battery specific capacity, specific power electrochemical performance reduction, etc., to achieve excellent high temperature characteristics, high current charging The effect of excellent discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

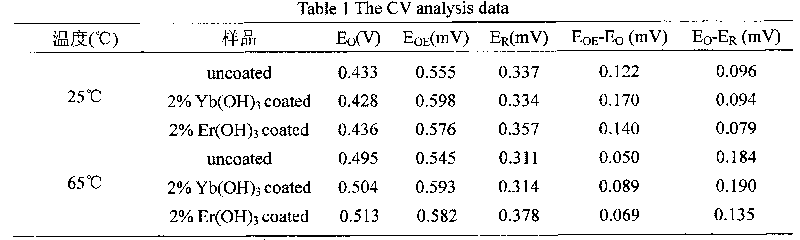

Embodiment 1

[0033] Take 2400g of Co2.0% spherical Ni(OH), add 2.88L of deionized water to form a 3L solution, stir evenly and add to the reactor, the mother liquor is continuously stirred in the reactor for 12h, and the temperature is controlled at 30°C; at 65L / h Add NaOH solution with a concentration of 7.95mol L-1 to the mother liquor, control the pH value in the reactor to 12, and control the reaction temperature at 50±2°C; add 0.05mol L-1 at a flow rate of 1400L / h 1YbCl3, continuously adjust the flow rate of the feed liquid, increase the flow rate by 2l / min, and control the pH value in the reactor to 12 at the same time to form a "gradient coating"; The complete feed liquid was released, aged for more than 12 hours, filtered, washed with deionized water until neutral, and dried at 80°C for 3 hours to obtain a Co-coated nickel hydroxide positive electrode material coated with Yb(OH)3 on the surface.

Embodiment 2

[0035] Take Co2.0% spherical Ni(OH)2 400g, add 2.88L of deionized water to form a 3L solution, stir evenly and add to the reactor, the mother liquor is continuously stirred in the reactor for 12h, and the temperature is controlled at 30°C; Add the prepared 7.95mol L-1NaOH solution into the mother liquor at a flow rate of h, control the pH value in the reactor to 12, and control the reaction temperature at 50±2°C; add 0.05mol L-1ErCl3 at a flow rate of 13001 / h , constantly adjust the flow rate of the feed liquid, increase the flow rate by 2l / min, and control the pH value in the reactor to 12 at the same time to form a "gradient coating". The feed liquid was released, aged for more than 12 hours, filtered, washed with deionized water until neutral, and dried at 80°C for 3 hours to obtain a Co-coated nickel hydroxide positive electrode material coated with Er(OH)3 on the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com