Lithium iron phosphate positive pole material

A cathode material, lithium iron phosphate technology, used in phosphorus compounds, battery electrodes, inorganic chemistry, etc., can solve the problem of low conductivity, and achieve the effect of good high current charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

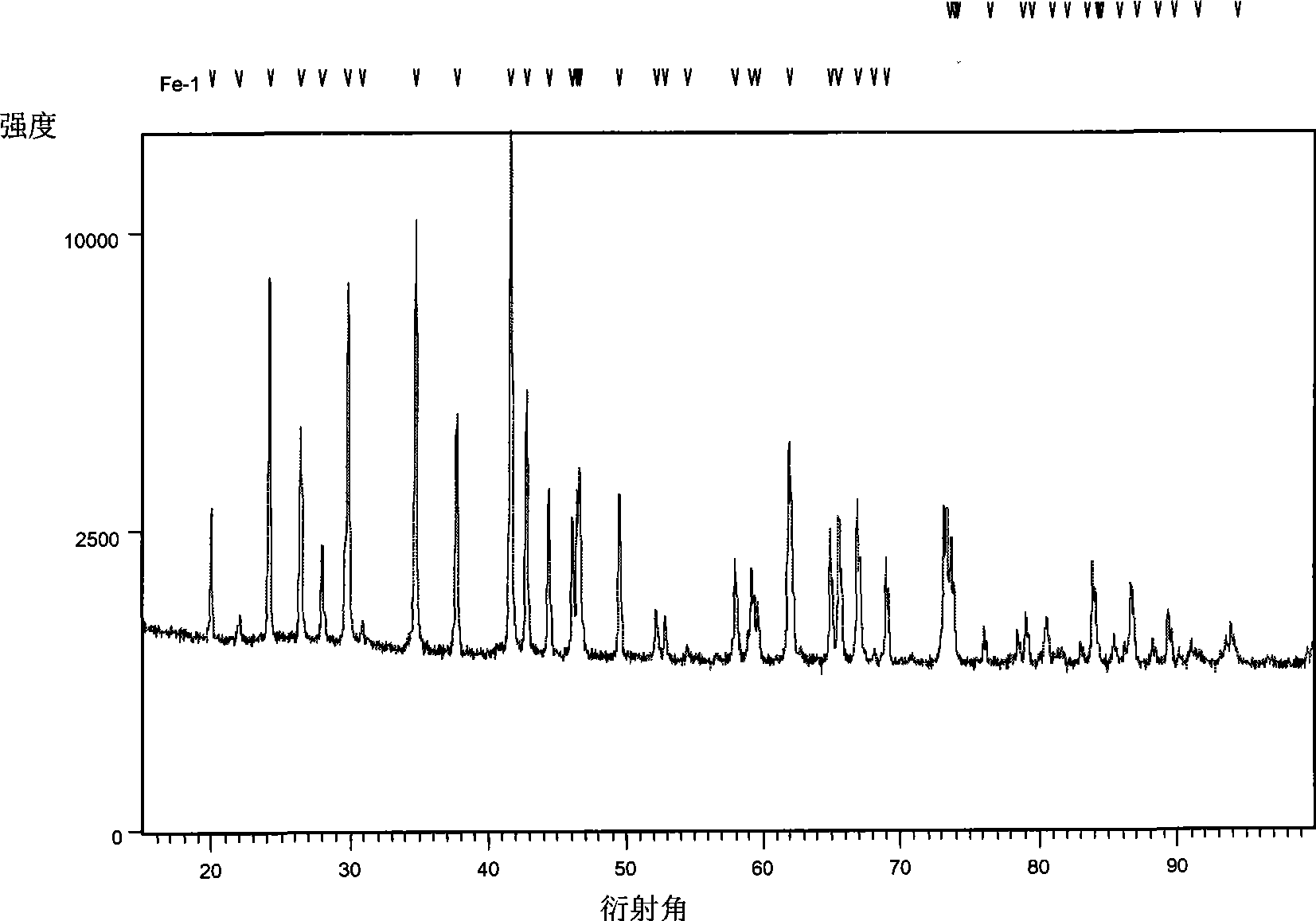

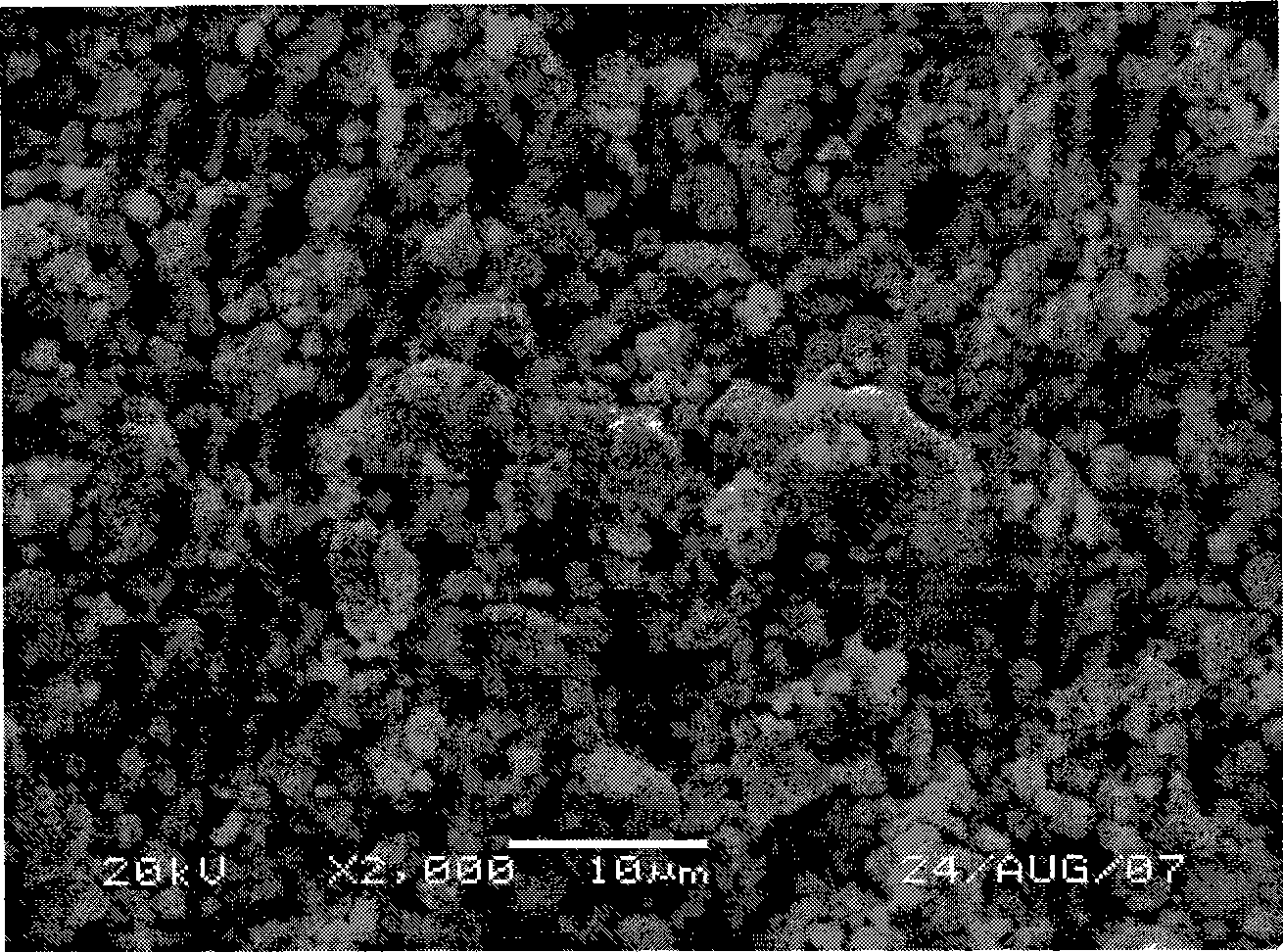

[0018] The carbon source is acetylene black, and the lithium source is Li 2 CO 3 , the iron source is FeC 2 o 4 2H 2 O, magnesium source is Mg(OH) 2 , the phosphorus source is NH 4 h 2 PO 4 , molar ratio FeC 2 o 4 2H 2 O: NH 4 h 2 PO 4 : Li 2 CO 3 :Mg(OH) 2 =1:1:0.96:0.02, the amount of acetylene black added is FeC 2 o 4 2H 2 O, NH 4 h 2 PO 4 , Li 2 CO 3 and Mg(OH) 2 12wt% of the sum of the amount used, disperse the above-mentioned components in acetone evenly, put them into a ball mill to grind, heat to evaporate the acetone, put the mixed and ground materials into a nitrogen atmosphere tube furnace, heat at 300°C for 12h, cold cut After grinding, pressing into blocks, calcining at 650°C for 24h in a nitrogen atmosphere tube test furnace, cold cutting, and grinding to obtain the Li 0.96 Mg 0.02 FePO 4 / C cathode material.

[0019] With Li 0.96 Mg 0.02 FePO 4 / C is the positive electrode active material, conductive carbon black is the conductive ...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is that the carbon source is tar, and the lithium source is LiOH·H 2 O, iron source is FeO, magnesium source is MgO, phosphorus source is (NH4) 3 PO 4 , molar ratio FeO:(NH4) 3 PO 4 :LiOH·H 2 O:MgO=1:1:0.98:0.01, tar addition is FeO, (N H 4) 3 PO 4 , LiOH·H 2 8wt% of the sum of the amount of O and MgO. The cathode material of this embodiment is Li 0.98 Mg 0.01 FePO 4 / C.

[0024] The 18650 type experimental battery was manufactured according to the same recipe and process as in Example 1.

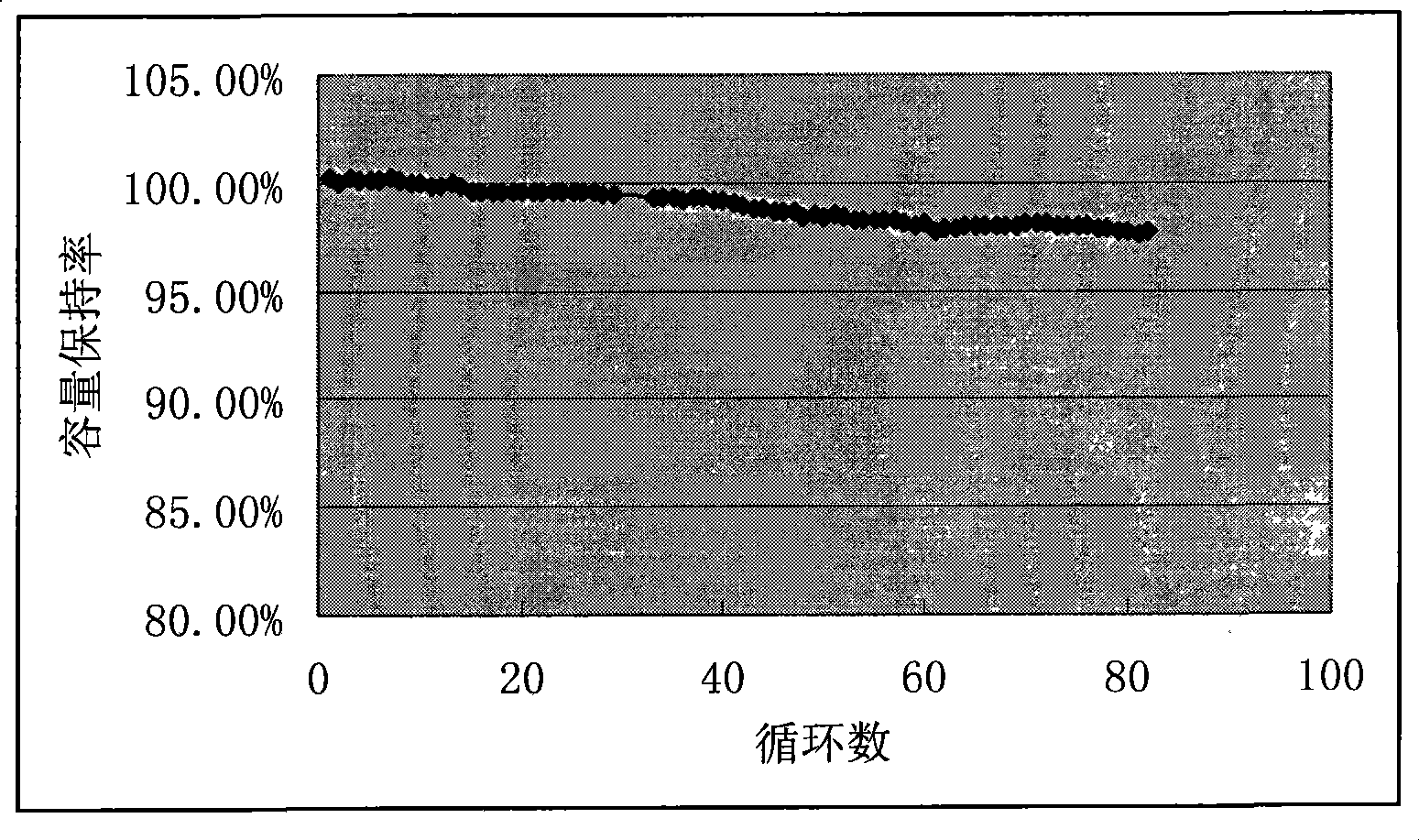

[0025] Carry out a cycle test of 5A charge / 15A discharge on the experimental battery, such as Figure 4 As shown, the capacity retention rate after 80 cycles is 97.81%. The initial discharge capacity of the sample battery reached 138.93mAh / g at room temperature.

Embodiment 3

[0027] The difference between this embodiment and embodiment one is: the carbon source is sucrose, and the iron source is Fe 2 o 3 , the magnesium source is Mg(H 2 PO 4 ) 2 2H 2 O, the phosphorus source is (NH 4 ) 2 HPO 4 , molar ratio Fe 2 o 3 :(NH 4 ) 2 HPO 4 : Li 2 CO 3 :Mg(H 2 PO 4 ) 2 2H 2 O=1:1:0.92:0.04, the amount of sucrose added is Fe 2 o 3 , (NH 4 ) 2 HPO 4 , Li 2 CO 3 and Mg(H 2 PO 4 ) 2 2H 2 15wt% of the sum of the amount of O used. The cathode material of this embodiment is Li 0.92 Mg 0.04 FePO 4 / C.

[0028] The 18650 type experimental battery was manufactured according to the same recipe and process as in Example 1.

[0029] Carry out a cycle test of 5A charge / 15A discharge on the experimental battery, such as Figure 4 As shown, the capacity retention rate after 80 cycles is 97.05%. The initial discharge capacity of the sample battery reached 139.46mAh / g at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com