A kind of lithium-ion battery composite graphite negative electrode material and preparation method thereof

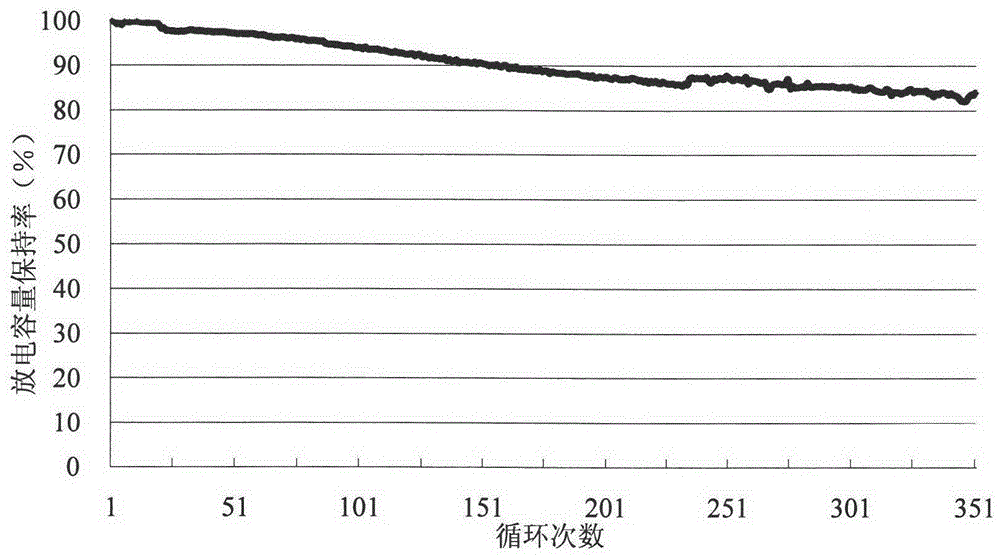

A lithium-ion battery, composite graphite technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low discharge capacity and poor cycle performance, and achieve good charge-discharge performance, high retention rate, and good electrochemical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. the volume average particle diameter D50 is 14kg of natural graphite of 19.3 μ m, the volume average particle diameter D50 is 6 kg of mesophase graphite and graphitization catalyst (SiC) 1.2 kg added in the cantilever double-helix conical mixer and mixed for 2 hours, To obtain the mixture; ② under stirring, alternately add 20kg of the mixture and 12kg of petroleum asphalt into the kneading pot, carry out kneading treatment at 160°C for 1 hour, after the kneading is completed, press it into a 2-5mm sheet in a tablet machine, and crush it into Powder with a particle size of 0.1mm or less is formed into briquettes; ③Under the protection of nitrogen, carbonize at 1100°C for 2 hours, then cool the reaction product to room temperature, and then carry out catalytic graphitization high-temperature treatment at 2800°C for 36 hours ; ④Use a jaw crusher for coarse crushing, and the particle size is controlled below 30mm; use a hammer crusher for medium crushing, and the particle...

Embodiment 2

[0040] 1. 10 kg of natural graphite with a volume average particle diameter D50 of 17.8 μm, 10 kg of mesophase graphite and graphitization catalyst (SiC) 1.2 kg with a volume average particle diameter D50 of 20.5 μm were added to a cantilever double-helix conical mixer and mixed for 2 hours, Obtain the mixture; ② under stirring, alternately add 20kg of the mixture and 3kg of petroleum asphalt into the kneading pot, carry out kneading treatment at 160°C for 1 hour, after the kneading is completed, press it into a 2-5mm sheet in a tablet machine, and crush it into Powder with a particle size of less than 0.1mm is formed into a compact; ③Under the protection of nitrogen, carbonize at 800°C for 6 hours, then cool the reaction product to room temperature, and then carry out catalytic graphitization at 3000°C for 48 hours Processing; ④Use a jaw crusher for coarse crushing, and the particle size is controlled below 30mm; use a hammer crusher for medium crushing, and the particle size ...

Embodiment 3

[0042] 1. the volume average particle diameter D50 is 15kg of natural graphite of 12.1 μ m, the volume average particle diameter D50 is 29.8 μ m of mesophase graphite 5 kg and graphitization catalyst (SiC) 1.2 kg is added in the cantilever double-helix conical mixer and mixed for 2 hours, Obtain the mixture; ② under stirring, alternately add 20kg of the mixture and 4kg of petroleum asphalt into the kneading pot, carry out kneading treatment at 100°C for 10 hours, after the kneading is completed, press it into a 2-5mm sheet in a tablet machine, and crush it into Powder with a particle size of 0.1mm or less is formed into a compact; ③Under the protection of nitrogen, carbonize at 1500°C for 3 hours, then cool the reaction product to room temperature, and then carry out catalytic graphitization at 3200°C for 48 hours Processing; ④Use a jaw crusher for coarse crushing, and the particle size is controlled below 30mm; use a hammer crusher for medium crushing, and the particle size is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com