Composite graphite negative electrode material, lithium ion secondary battery, preparation method and application

A negative electrode material and composite graphite technology, which is applied in the field of composite graphite negative electrode materials, can solve the problems of large expansion, poor circulation, and low discharge capacity of composite graphite negative electrode materials, and achieve reduced specific surface area, improved discharge efficiency, and high-current charge and discharge performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

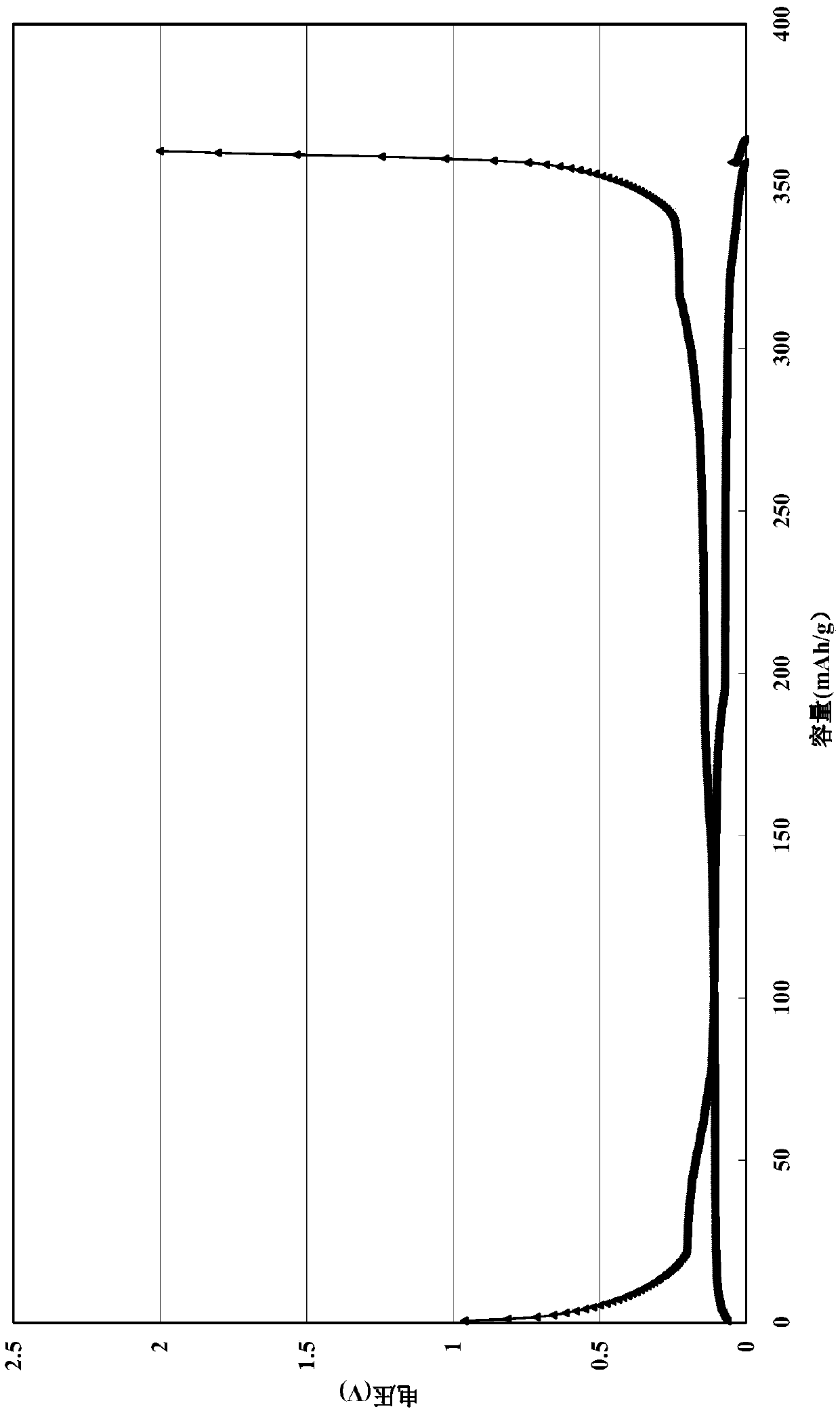

Image

Examples

Embodiment 2

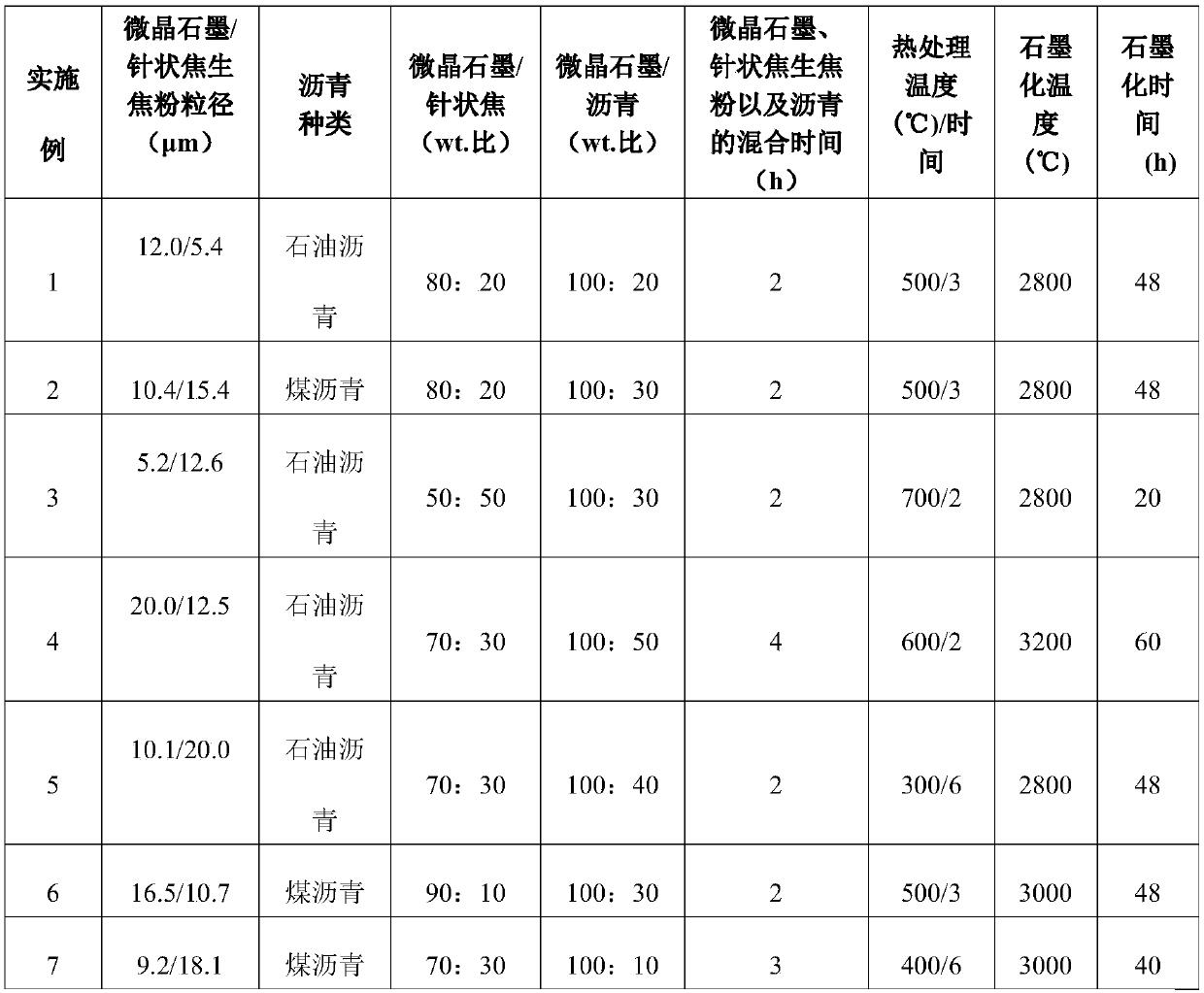

[0054] Add 80kg of microcrystalline graphite (D50 is 10.4μm), 20kg of needle coke raw coke powder (D50 is 15.4μm) and 30kg of coal tar pitch into the mixer and mix for 2 hours. Under the protection of nitrogen, heat treatment is carried out, and the final temperature is 500 ℃, after finishing, carry out graphitization high-temperature treatment (2800 ℃, 48 hours) after reaction product is cooled to room temperature, make composite graphite anode material of the present invention, half cell capacity 368.5mAh / g, initial efficiency 92.6%, discharge rate ( 10C / 0.2C) 93.1%.

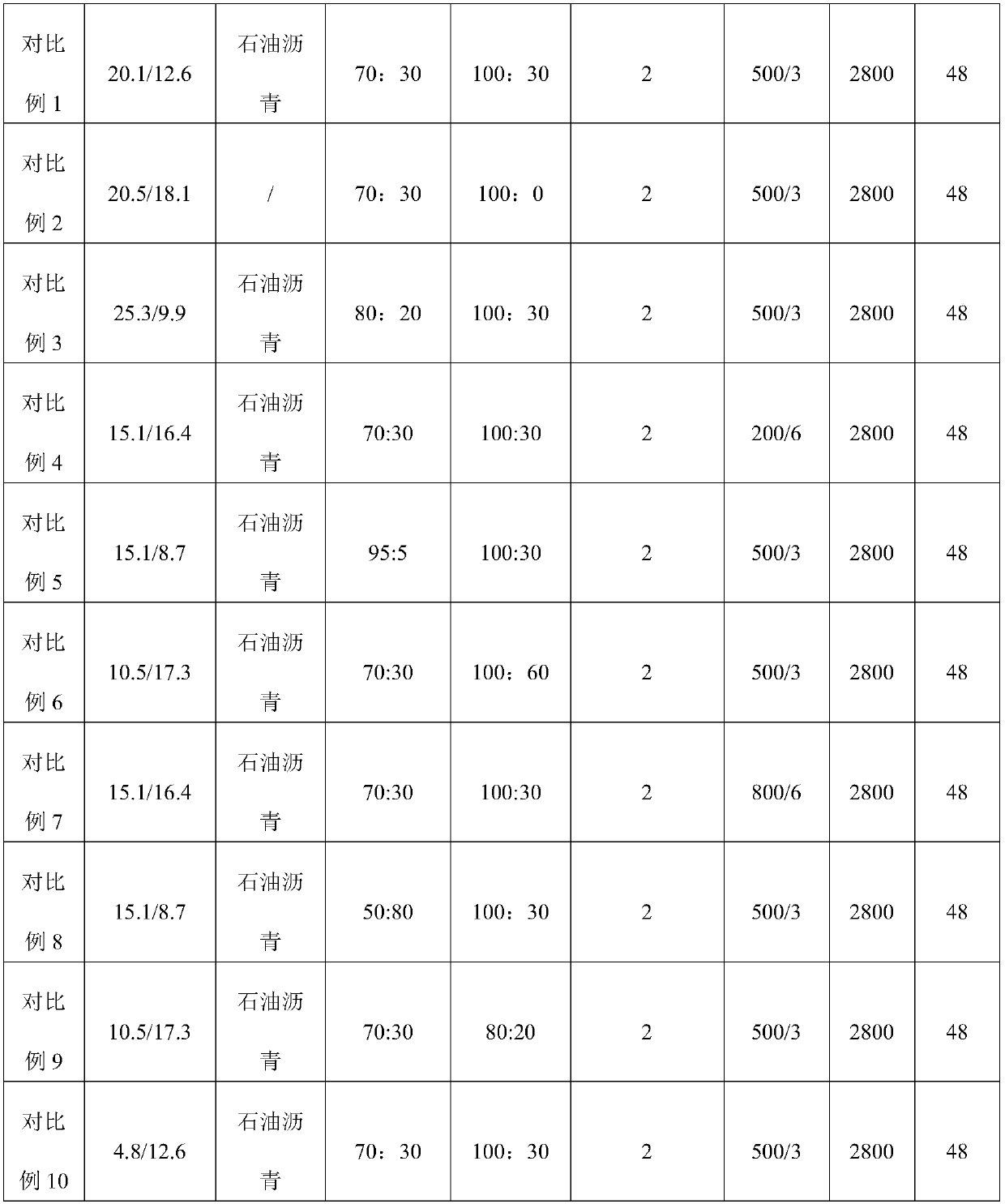

[0055] The performance parameters of each embodiment and comparative examples are shown in table 3 below:

[0056] table 3

[0057]

[0058] As can be seen from the above data: the discharge capacity and charge-discharge efficiency in the comparative example are low, wherein,

[0059] The particle size of microcrystalline graphite in Comparative Examples 1 and 3 is too large (D50 is 20.1 μm and 25.3 μm re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com