Catalyst for m-toluidine prepared from m-nitrotoluene through gas phase hydrogenation, preparation method and regeneration method thereof

A technology of nitrotoluene and catalyst, which is applied in the field of catalyst for preparing m-toluidine by gas-phase hydrogenation of m-nitrotoluene and its preparation field, which can solve problems such as high equipment operation and maintenance costs, difficulties in continuous production, and non-existence of regeneration methods , to achieve the effects of long service life, simple preparation process and regeneration process, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

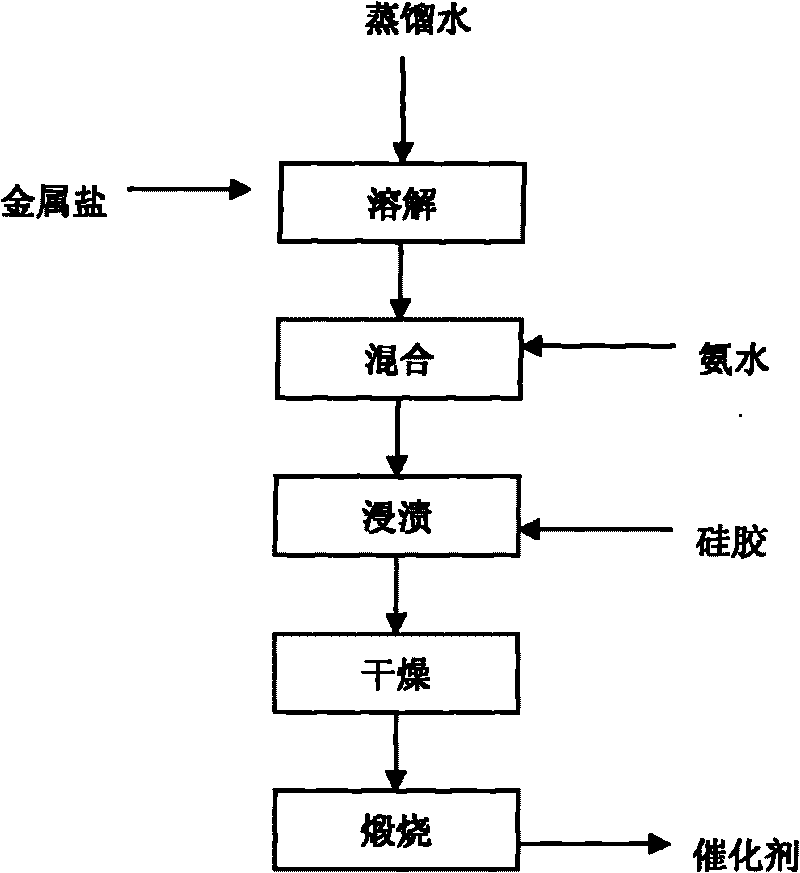

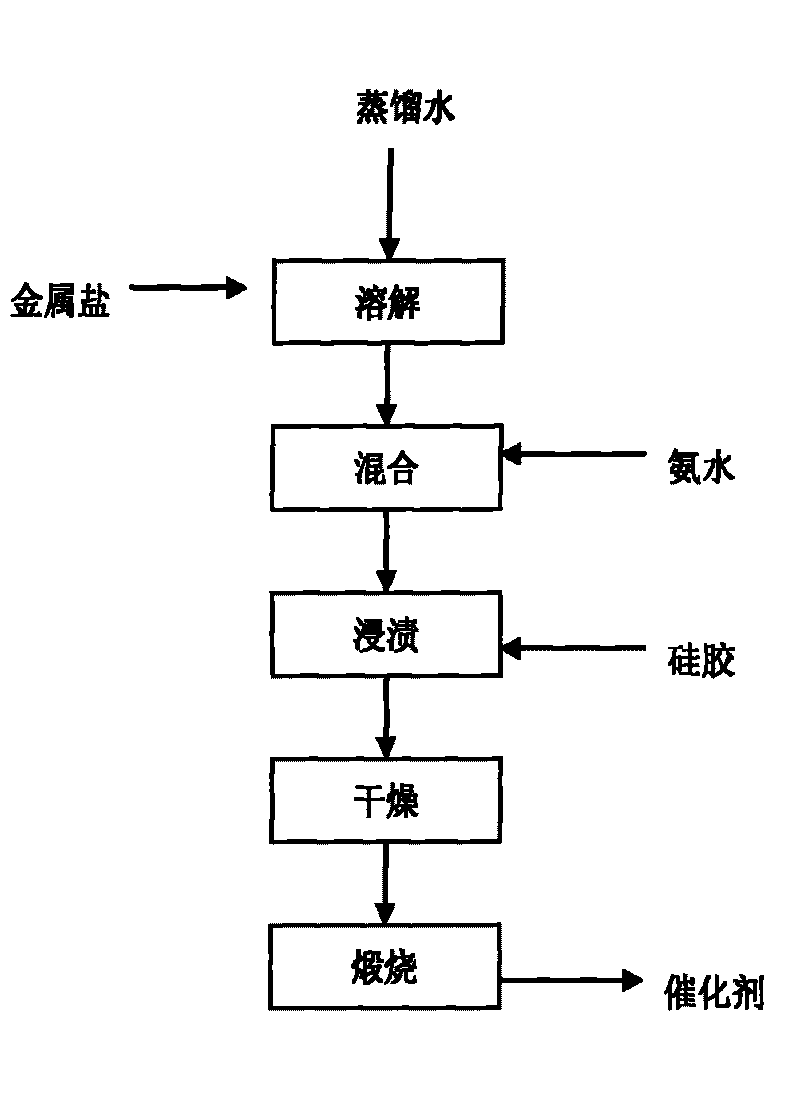

Method used

Image

Examples

Embodiment 1

[0013] Catalyst composition: Cu accounted for 10% SiO 2 90%

[0014] Preparation method: Weigh 12.9g Cu(NO 3 ) 2 .6H 2 O and 25g silica gel, in Cu(NO 3 ) 2 .6H 2 Add 50ml of distilled water to O until it is completely dissolved; add 50ml of ammonia solution with a weight percentage of 10-25% until no precipitation is formed in the solution; adjust the pH value to 8-10, add silica gel to the prepared solution, and Stir mechanically at ~80°C for 2-10 hours; filter and wash the obtained solution until the filtrate is colorless and dry at 110-130°C for 3-5 hours, then roast it at 300-500°C for 3-5 hours After 6 hours, Cu accounted for about 10% in the obtained catalyst based on the weight of the catalyst.

Embodiment 2

[0016] Catalyst composition: Cu accounted for 20% SiO 2 80%

[0017] Preparation method: Weigh 29.2g Cu(NO 3 ) 2 .6H 2 O and 25g silica gel, in Cu(NO 3 ) 2 .6H 2 O Add 50ml of distilled water until it is completely dissolved; add 50ml of ammonia solution with a weight percentage of 10-25%, until no precipitation is formed in the solution; adjust the pH value to 8-10, add silica gel to the prepared solution, at 50- Stir mechanically at 80°C for 2-10 hours; filter and wash the obtained solution until the filtrate is colorless and dry at 110-130°C for 3-5 hours, then roast it at 300-500°C for 3-6 hours At this time, Cu accounted for about 20% of the obtained catalyst based on the weight of the catalyst.

Embodiment 3

[0019] Catalyst composition: Cu accounted for 30% SiO 2 70%

[0020] Preparation method: Weigh 49.6g Cu(NO 3 ) 2 .6H 2 O and 25g silica gel, in Cu(NO 3 ) 2 .6H 2 Add 50ml of distilled water to O until it is completely dissolved; add 50ml of ammonia solution with a weight percentage of 10-25% until no precipitation is formed in the solution; adjust the pH value to 8-10, add silica gel to the prepared solution, and Stir mechanically at ~80°C for 2-10 hours; filter and wash the obtained solution until the filtrate is colorless and dry at 110-130°C for 3-5 hours, then roast it at 300-500°C for 3-5 hours After 6 hours, Cu accounted for about 30% of the obtained catalyst based on the weight of the catalyst.

[0021] Process implementation: use m-nitrotoluene fixed-bed gas-phase hydrogenation reactor to evaluate the catalyst, put 5ml of the prepared catalyst into the fixed-bed reactor, and first carry out constant temperature treatment of the catalyst: after the other gases in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com