Method for preparing urchin-shaped hydroxyferric oxide and urchin-shaped ferric oxide nano material

A nanotechnology of iron oxyhydroxide and iron oxide, which is applied in the field of nanomaterials, can solve the problems of low specific surface area of materials that cannot meet actual needs, unfavorable regulation of product microstructure, and low efficiency, and achieve excellent catalytic properties, high structural purity, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 17.80g of glucose, 16.68g of ferrous sulfate and 1000mL of deionized water into a three-necked flask, feed 1.0L / min air at a certain temperature (such as: 80°C), stir and reflux for a certain period of time for 10h, wash and filter , and dried in vacuum at 80°C for 12h to obtain yellow-green α-FeOOH. The morphology of the obtained product is as figure 1 and figure 2 Shown is the structure of a sea urchin.

Embodiment 2

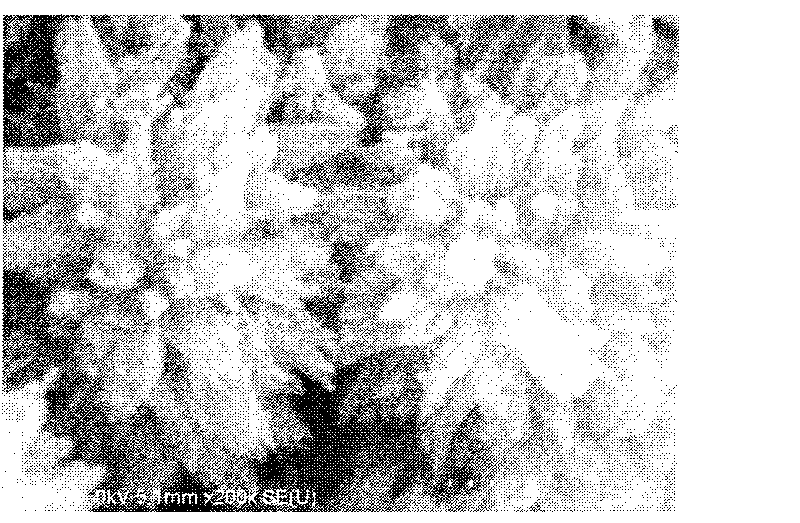

[0039] The product obtained in embodiment 1 carries out phase analysis (as image 3 shown). The phase is only α-FeOOH, no other impurity exists. Its specific surface area is calculated to be 61.1m by nitrogen adsorption / desorption curve test 2 / g.

Embodiment 3

[0041] Using the process in Example 1, when the reaction time is 30 minutes, the sea urchin structure α-FeOOH can also be obtained. The morphology of the obtained product is as Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com