Method for producing 4-N,N-dimethylamino methylaniline

A technology of dimethylaminomethylaniline and nitrobenzene, which is applied in the field of organic compound synthesis, can solve problems to be improved and the like, and achieves the effects of being suitable for large-scale production, mild reaction conditions and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

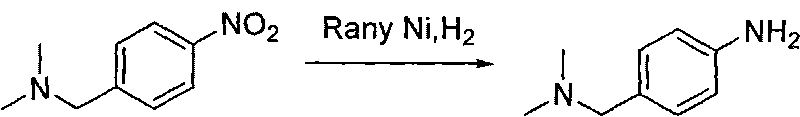

Image

Examples

Embodiment 1

[0013] The compound nitrobenzene (12.87g, 0.0715mol) was dissolved in 56ml of ethanol, 1% Rany Ni was added thereto, and the hydrogen pressure was kept at 1 atm, and the mixture was stirred for 2 days at a temperature of 80°C. After the reaction was completed, the reaction solution was filtered and concentrated, and distilled under reduced pressure to obtain 9.7 g of a light yellow liquid 4-N,N-dimethylaminomethylaniline, with a yield of 90%.

Embodiment 2

[0015] The compound nitrobenzene (12.87 g, 0.0715 mol) was dissolved in 56 ml of methanol, 10% Rany Ni was added thereto, and the hydrogen pressure was kept at 0.5 atm, and the mixture was stirred for 6 hours at a temperature of 70°C. After the reaction was completed, the reaction solution was concentrated by filtration and concentrated under reduced pressure to obtain 9.9 g of a light yellow liquid 4-N,N-dimethylaminomethylaniline, with a yield of 92%.

Embodiment 3

[0017] Compound nitrobenzene (12.87g, 0.0715mol) was dissolved in 56ml of isopropanol, 20% Rany Ni was added thereto, and the pressure of hydrogen was maintained at 0.1-1 atm. When the temperature was 30°C, it was stirred for 36 hours. After the reaction was completed, the reaction solution was filtered and concentrated, and distilled under reduced pressure to obtain 10.1 g of a light yellow liquid 4-N,N-dimethylaminomethylaniline, with a yield of 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com