Preparation method of arctigenin

A technology of arctigenin and arctium seed is applied in the field of preparation of arctigenin, can solve the problems of unsafe, unfavorable industrialized production, high price and the like, and achieves the effect suitable for industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

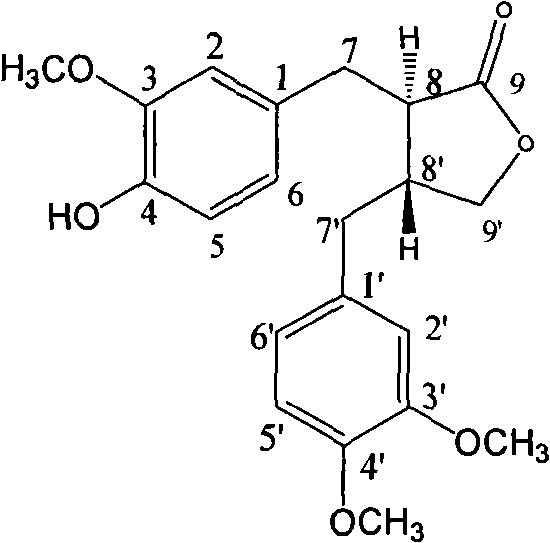

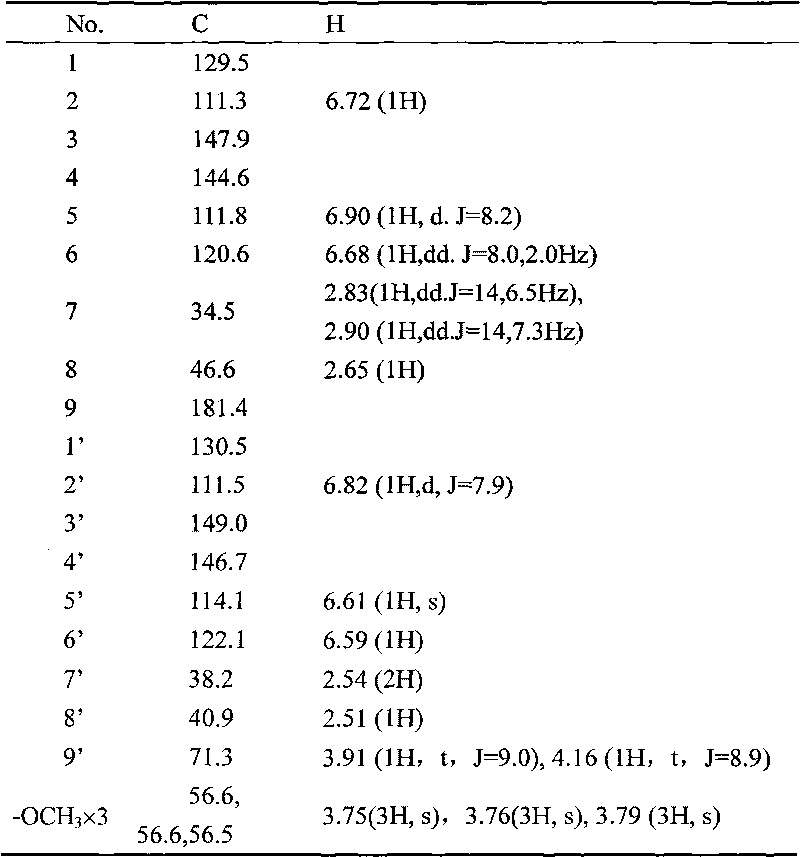

Image

Examples

Embodiment 1

[0016] Take 100 grams of burdock fruit, crush it, pass it through a 10-mesh sieve, add 500 ml of water, enzymolyze it at 25°C for 2 hours, let it rest, and filter. Concentrate the filtrate to about one-third under reduced pressure, add ethanol to make a 20% ethanol aqueous solution, add it to the medicinal material residue, reflux for extraction for 1 hour, and filter. The residue was further extracted with 20% ethanol twice for one hour each time. The combined extracts were concentrated to near dryness under reduced pressure. Then column chromatography separation was performed 3 times. Mix the sample with the same amount of sample mixing silica gel (100-120 mesh) as the extract each time, and the column chromatography silica gel is 10 times the sample amount. Elute with chloroform-methanol, the volume ratio of chloroform-methanol is 100:0-95:5. Fractions containing arctigenin were combined and evaporated to dryness. Repeated recrystallization with methanol or ethanol (95%...

Embodiment 2

[0018] Take 100 grams of burdock fruit, crush it, pass it through a 60-mesh sieve, add 1500 ml of water, enzymolyze it at 35°C for 12 hours, let it rest, and filter. Concentrate the filtrate to about one-third under reduced pressure, add ethanol to form a 60% ethanol aqueous solution, add it to the medicinal material residue, reflux for extraction for 3 hours, and filter. The residue was further extracted with 30% ethanol twice for one hour each time. The combined extracts were concentrated to near dryness under reduced pressure. Then column chromatography separation was performed twice. Mix the sample with the same amount of sample mixing silica gel (100-120 mesh) as the extract each time, and the column chromatography silica gel is 5 times the sample amount. Elute with chloroform-methanol, the volume ratio of chloroform-methanol is 100:0-95:5. Fractions containing arctigenin were combined and evaporated to dryness. Repeated recrystallization with methanol or ethanol (95%...

Embodiment 3

[0020] Take 100 grams of burdock fruit, crush it, pass it through a 20-mesh sieve, add 1000 ml of water, enzymolyze it at 50°C for 8 hours, let it rest, and filter. The filtrate was concentrated under reduced pressure to nearly dryness, added 95% ethanol aqueous solution, added to the medicinal material residue, extracted under reflux for 3 hours, and filtered. The residue was extracted twice with 95% ethanol for one hour each time. The combined extracts were concentrated to near dryness under reduced pressure. Then column chromatography separation was performed twice. Mix the sample with the same amount of sample mixing silica gel (100-120 mesh) as the extract each time, and the column chromatography silica gel is 20 times the sample amount. Elute with chloroform-methanol, the volume ratio of chloroform-methanol is 100:0-95:5. Fractions containing arctigenin were combined and evaporated to dryness. Repeated recrystallization with methanol or ethanol (95%, analytically pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com