System and method for embedding optical fiber grating sensor in fiber high polymer composite material

A fiber grating and composite material technology, applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., can solve the problems of complex process and poor embedding effect, and achieve simple preparation process and excellent embedding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

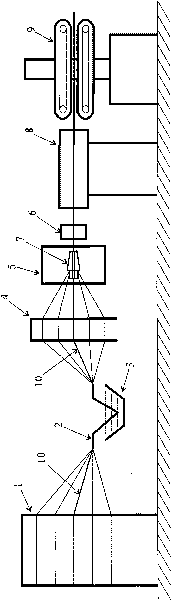

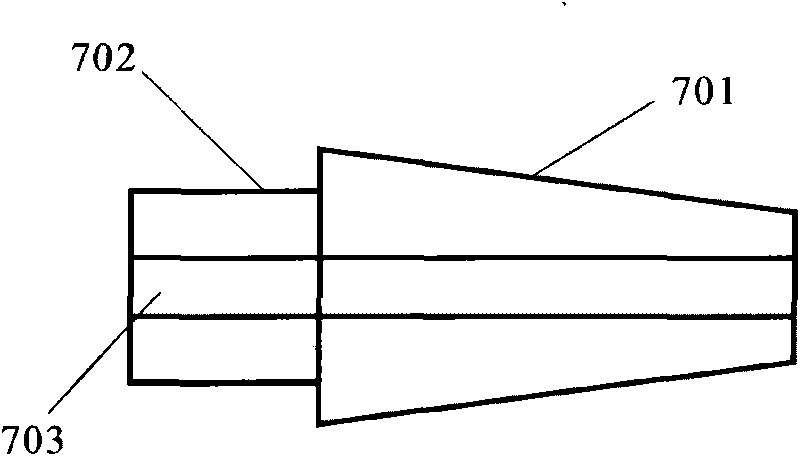

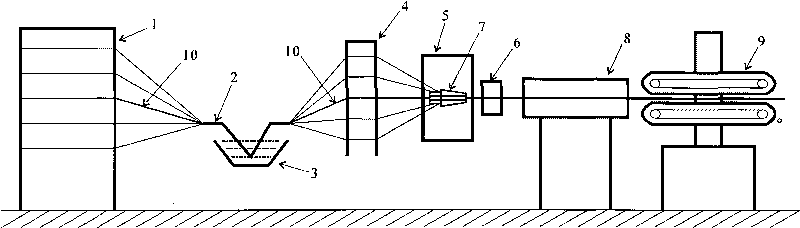

[0018] Please also refer to figure 1 and figure 2 , figure 1 It is a structural diagram of the system of the present invention, figure 2 It is a structural diagram of the lead-in die needle of the present invention. As shown in the figure, the fiber grating sensor is embedded in the fiber polymer composite material system, with fiber bundles and fiber grating sensors 10 passing through the fiber frame 1, fiber guide jointer 2, resin impregnation tank 3, fiber tension distributor 4. Pultrusion die head 5, glue remover 6, heating and curing device 8 and traction device 9, wherein, the introduction die needle 7 is built in the middle part of the pultrusion die head 5, and the introduction die needle 7 has a pagoda-shaped die head 701 One end of the threaded connector 702 is mounted on the tail of the die needle head 701, and the other end of the threaded connector 702 and the head of the die needle head 701 are provided with a mutual penetration hole 703, the central axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com