Improved wind load pressure sensor

A pressure sensor and wind load technology, applied in the direction of fluid pressure measurement by changing ohmic resistance, can solve the problems of error, resistance to wind and rain, high cost, etc., to achieve application value, eliminate environmental temperature changes, and facilitate The effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

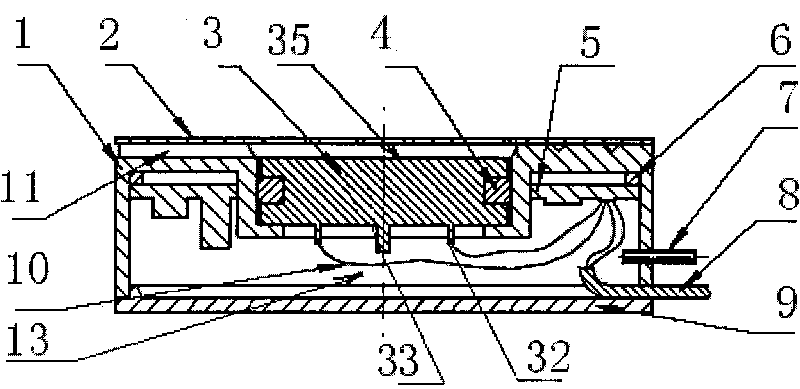

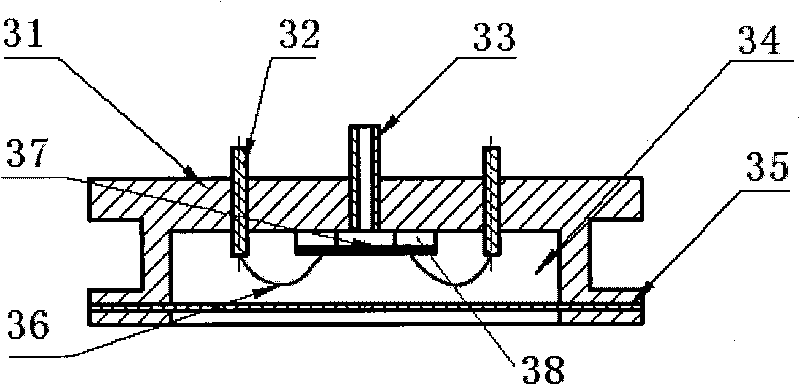

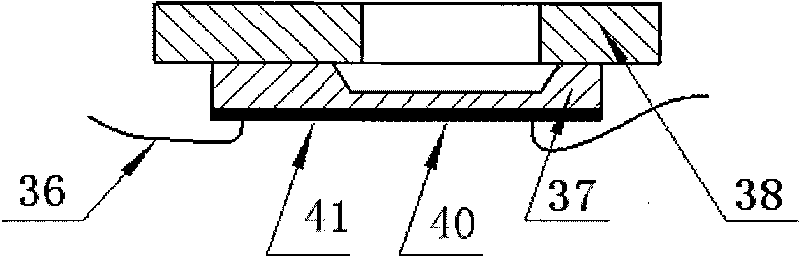

[0036] combine figure 1 , figure 2 , image 3 and Figure 4 , as further described below:

[0037] An improved wind load pressure sensor, comprising a sensor housing, an oil-filled sensitive body 3 and a signal conditioning circuit board 5 (such as figure 1 shown), the sensor housing is composed of a flat tube-shaped base 1 and a bottom plate 9 sealed and fixed at the bottom of the base, the oil-filled sensitive body 3 is composed of a grooved sensitive body housing 31, a silicon integrated sensitive chip 37 and the elastic isolation film 35 that is sealed and fixed on the groove mouth are formed (such as figure 2 As shown), the surrounding part of the sensitive body housing 31 is sealed and fixed in the step hole at the front end of the base through the sealing ring 4, and the upper hole of the step hole becomes a pressure sensitive port because the elastic isolation diaphragm is exposed, (see figure 1), the back pressure surface of the silicon integrated sensitive chi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com