GaN based LED epitaxial wafer of graphical substrate and method for preparing same

A technology for LED epitaxial wafers and graphic substrates, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of not improving the quality of GaN crystals, poor quality of GaN epitaxial crystals, and singleness, and improve the external quantum efficiency. , The effect of improving crystal quality and improving light output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

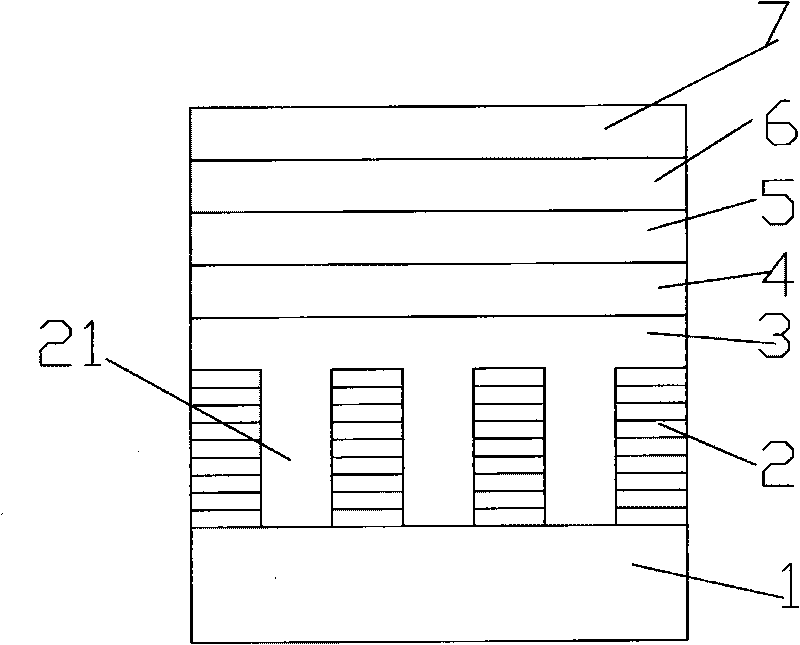

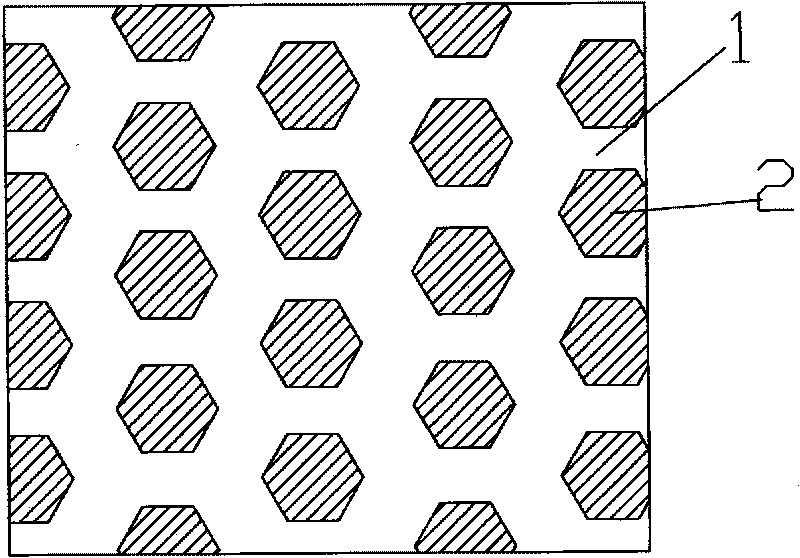

[0046] like figure 2 As shown, the pattern structure described in the embodiment of the present invention is a regular hexagon, the width a of the pattern structure is 6 micrometers, and the distance b between adjacent patterns is 4 micrometers; the SiO 2 The number of alternating cycles with SiON is 8 times; the SiO described in the embodiment of the present invention 2 Alternating layers with SiON each have a thickness of 58nm and 64nm, respectively.

Embodiment 2

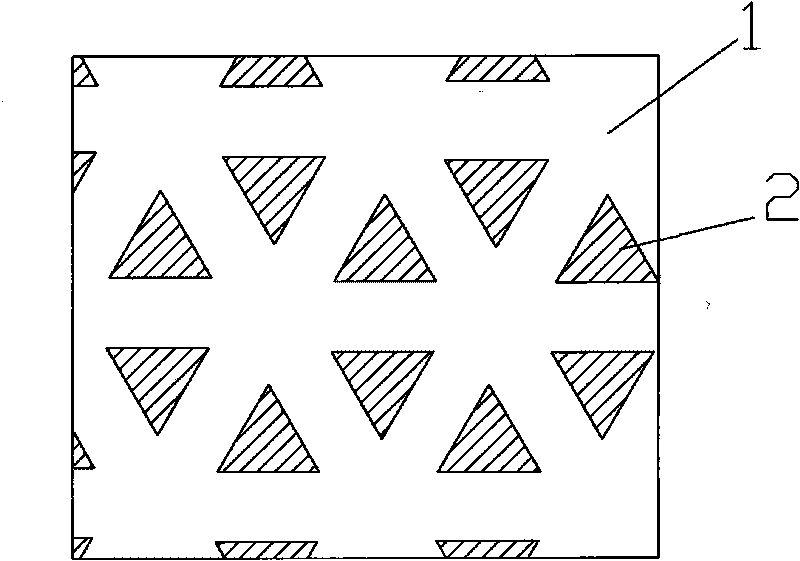

[0048] like image 3 As shown, the pattern structure described in the embodiment of the present invention is an equilateral triangle, the width a of the pattern structure is 3 microns, and the spacing b between adjacent patterns is 2 microns; the SiO 2 The number of alternating cycles with SiON is 16 times; the SiO described in the embodiment of the present invention 2 Alternating layers with SiON each have a thickness of 68nm and 75nm, respectively.

Embodiment 3

[0050] like Figure 4 As shown, the pattern structure described in the embodiment of the present invention is a square, the width a of the pattern structure is 10 microns, and the distance b between adjacent patterns is 6 microns; the SiO 2 The number of alternating cycles with SiON is 4 times; the SiO described in the embodiment of the present invention 2 Alternating layers with SiON each have a thickness of 58nm and 64nm, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com