Hybrid power system

A hybrid system and engine technology, applied in hybrid vehicles, motor vehicles, electric vehicles, etc., can solve the problems of long start-up time, high start-up energy consumption, large motor load and impact, etc., to reduce wear and save synchronization. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

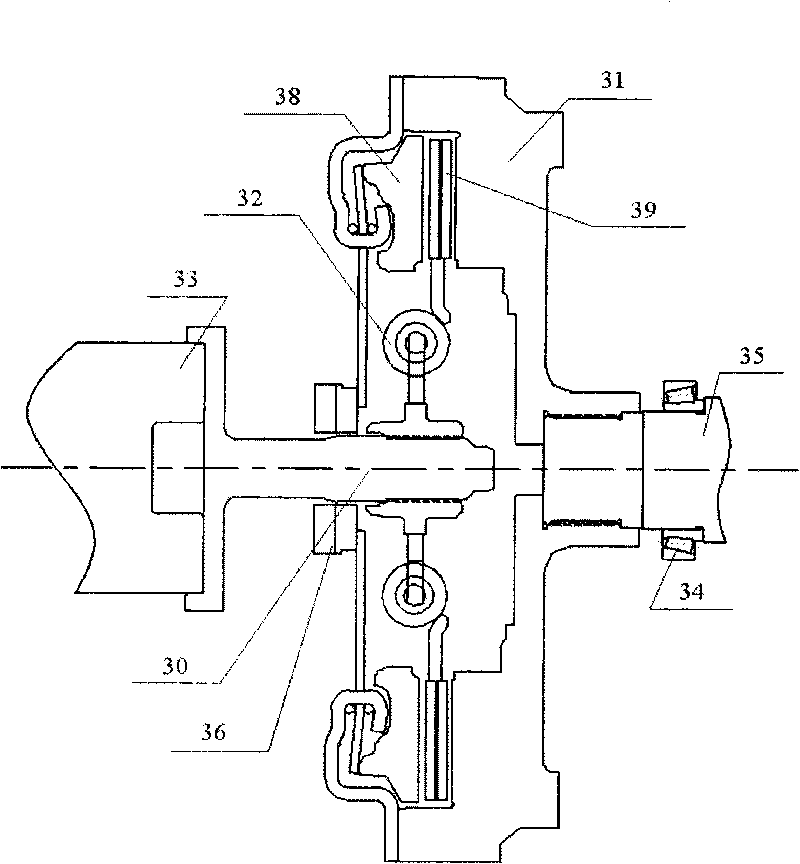

[0024] Such as image 3 As shown, in the hybrid power system of the present invention, the mode clutch is installed in such a way that the clutch friction disc 39 as a small inertia part is installed on the spline at one end of the adapter shaft 30 through the torsional shock absorber 32, and the adapter The other end of the shaft 30 is connected to the output end 33 of the engine crankshaft, and a release bearing 36 is arranged on the adapter shaft 30 on the side near the output shaft 33 of the engine crankshaft of the mode clutch. On the other side, the clutch pressure plate 38 is installed on the flywheel 31, so that the clutch pressure plate 38 and the flywheel 31 as a large inertia part have just been installed on the motor input shaft 35. Specifically, the flywheel is combined with the motor input shaft through a flat key or spline on its own structure, or connected with the motor input shaft through bolts. In order to bear the axial force, an angular contact bearing 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com