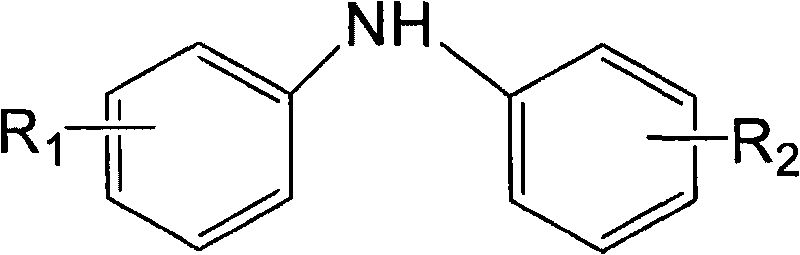

Catalyst and diphenylamine alkylation method

A technology of alkylation and catalyst, which is applied in the field of catalyst and alkylation of diphenylamine, which can solve the problems of poor catalyst reusability and large amount of catalyst, and achieve the effect of good reusability and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of the catalyst provided by the invention comprises contacting an acid aqueous solution with a concentration of 20% by weight or less with activated clay, dehydrating and drying.

[0017] According to the preparation method provided by the present invention, preferably, the concentration of the acid is lower than 20% by weight, preferably 1-12% by weight, more preferably 1-10% by weight. And the acid may be various acids known to those skilled in the art, such as water-soluble mineral acid and / or p-toluenesulfonic acid. Wherein the water-soluble inorganic acid can be selected from one or more of sulfuric acid, phosphoric acid, hydrochloric acid, phosphotungstic acid and phosphomolybdic acid. The selected acid is preferably one or more of sulfuric acid, phosphoric acid, hydrochloric acid and p-toluenesulfonic acid.

[0018] According to the preparation method provided by the present invention, preferably, the temperature of the immersion is 20-80°...

Embodiment 1

[0034] 1. Preparation of catalyst

[0035] Adopt equal volume impregnation method to impregnate activated clay (Jinzhou Yixian Petroleum Clay Co., Ltd. product) in the sulfuric acid that temperature keeps on 20 ℃, concentration is 2% by weight, soaks 2 hours, then distills off water, dries at 100 ℃ for 2 hours hours, the catalyst was obtained.

[0036] 2. Preparation of alkylated diphenylamine

[0037] Add 50.7 g of diphenylamine, 60.5 g of diisobutylene, and 2 g of the catalyst prepared above into a 250 ml autoclave, and replace the reaction system with nitrogen three times. Start to heat up, and start stirring at a speed of 200 rpm when the temperature reaches 100°C. When the temperature is raised to 170° C. and the pressure of the reaction system is 0.30 MPa, the timing starts. After 10 hours of reaction, the pressure gradually decreases to 0.17 MPa as the reaction progresses. The residual diphenylamine content is lower than 4 wt. %, the reaction ends at this point. The...

Embodiment 2

[0039] 1. Preparation of catalyst

[0040] Adopt equal volume impregnation method to impregnate activated clay (Jinzhou Yixian Petroleum Clay Co., Ltd. product) in the sulfuric acid that temperature keeps on 30 ℃, concentration is 4% by weight, soaks 3 hours, distills off water then, dries at 120 ℃ for 3 hours hours, the catalyst was obtained.

[0041] 2. Preparation of alkylated diphenylamine

[0042] Add 50.7 g of diphenylamine, 67.2 g of diisobutylene, and 3 g of the catalyst prepared above into a 250 ml autoclave, and replace the reaction system with nitrogen three times. Start to heat up, and start stirring at a speed of 200 rpm when the temperature reaches 100°C. When the temperature is raised to 170° C. and the pressure of the reaction system is 0.38 MPa, the timing starts. After the reaction is carried out for 12 hours, the pressure gradually decreases to 0.15 MPa as the reaction progresses. The residual diphenylamine content is lower than 4 wt. %, the reaction ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com