Laser roller film engraving machine

An engraving machine and laser technology, applied in laser welding equipment, optics, nonlinear optics, etc., can solve the problems of low beam quality and increased cost, and achieve increased laser output energy, precise laser processing, enlarged diameter and light receiving corner effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

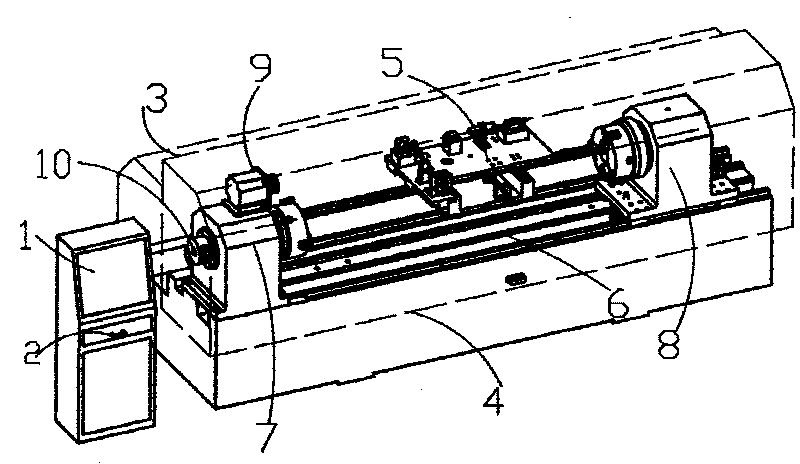

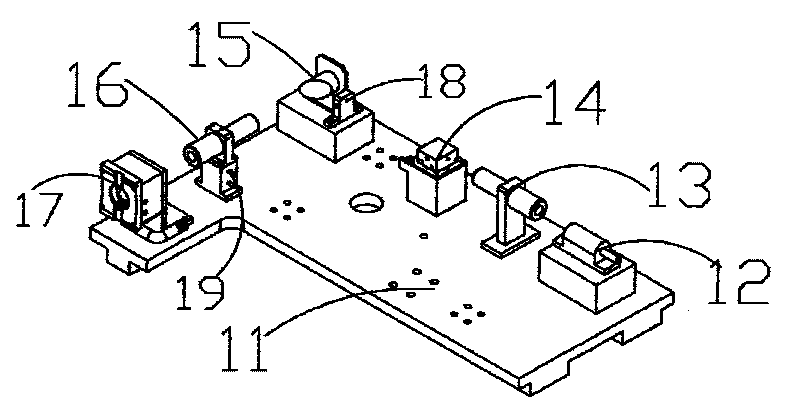

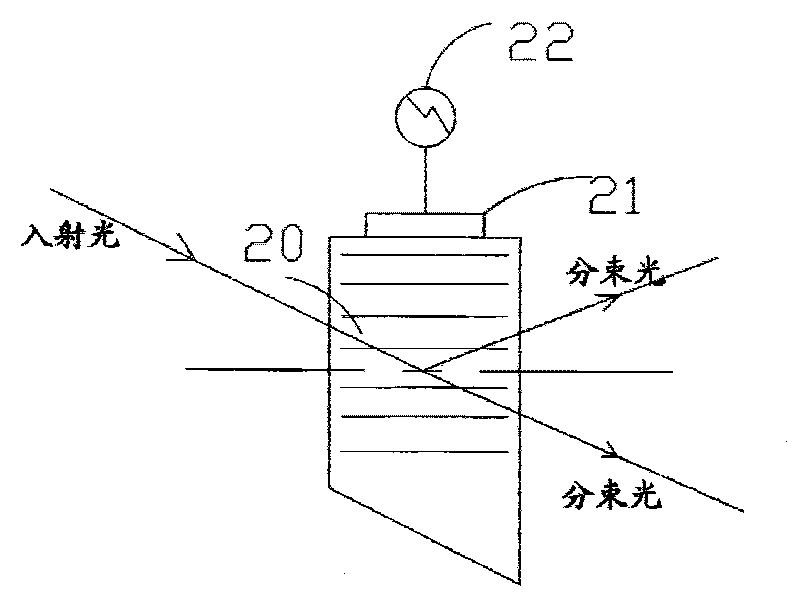

[0014] Such as figure 1 , 2 As shown, the present invention includes: a graphic image processing system 1, a control system 2, a body 4, and an optical system 5; wherein the body 4 includes a workbench 6 and a protective cover 3, and the workbench 6 includes a front support for supporting a processing plate roller 7 and tailstock 8, the front support 7 is fixed on the workbench 6, the tailstock 8 is set on the guide rail of the workbench 6, the front support 7 is equipped with a servo motor 9 and an encoder 10, the servo motor 9 and the encoder 10 It is connected with the main shaft inside the front support 7; the optical system 5 is set on a supporting plate 11, and the supporting plate 11 is set on the workbench 6; The deflector 14, the reflector 15, the beam expander 16, and the beam expander 16 include a height-adjustable adjustment table 19 and a light carving head 17. The laser generator 12 includes an interface with a heat sink. The beam mirror 13 enters the acousto-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com