Method for producing alumina from bauxite

A technology of bauxite and alumina, which is applied in the preparation of alkali metal aluminate/alumina/hydroxide, etc., can solve the problems of unindustrialized reports, low alumina concentration, and large water evaporation, and achieve Overcoming the harsh operating conditions, reducing the loss of lye, and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

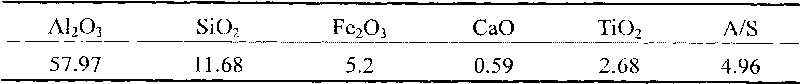

[0051] With the method for clean production of alumina by using low-grade diaspore bauxite of the present invention, a certain bauxite in Sanmenxia, Henan is used as raw material to produce alumina, and the raw material composition of a certain bauxite in Sanmenxia, Henan (mass percentage, wt%, the same below) as described in Table 1:

[0052] Table 1

[0053]

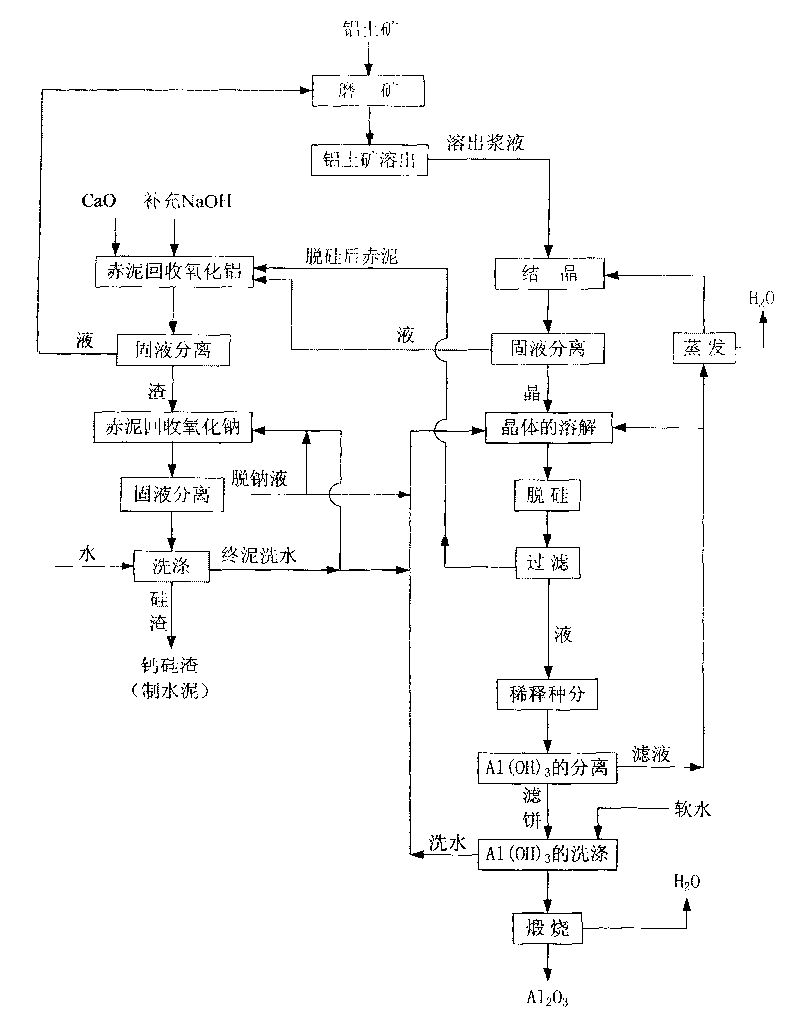

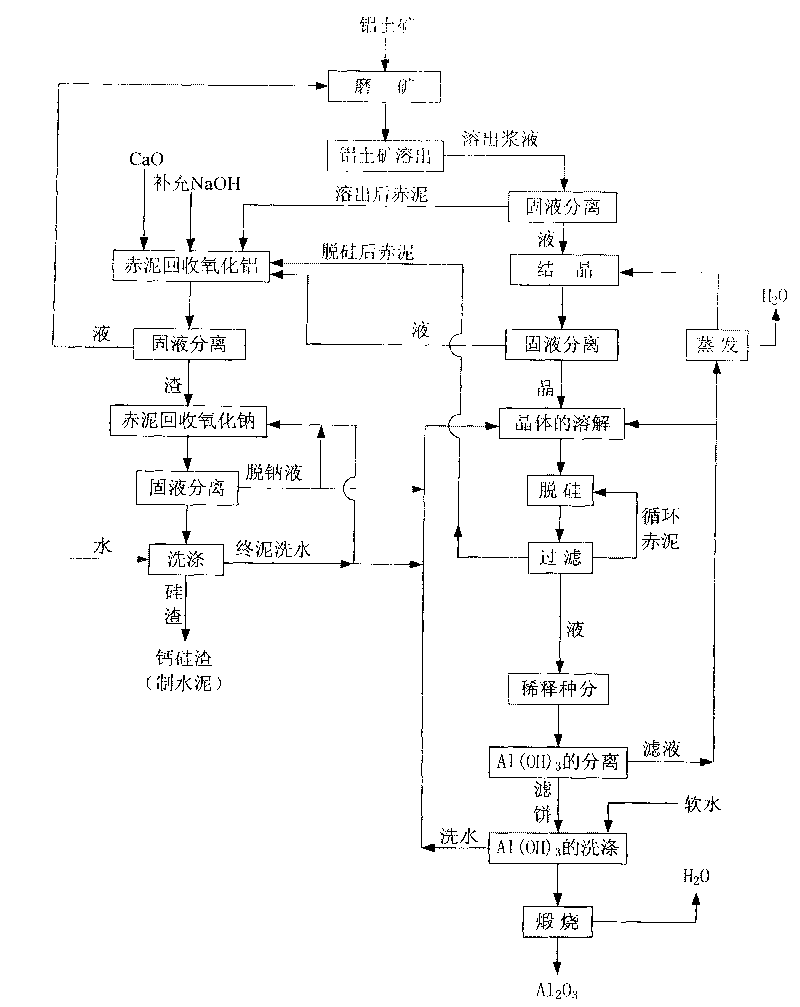

[0054] Its production process is as figure 1 The methods shown include:

[0055] 1. Mix a certain bauxite in Sanmenxia, Henan Province, which is ground to 74-150 μm, with 40% by mass sodium hydroxide solution, and carry out dissolution reaction in a high-pressure reactor. The mass ratio of bauxite to sodium hydroxide solution is 1:3.5, the stripping reaction temperature is 200°C, the reaction pressure is 0.7MPa, and the stripping time is 1 hour to obtain a solid-liquid mixture of the stripping solution containing sodium aluminate and slag, and the relative stripping rate of alumina entering the solution is ...

Embodiment 2

[0062] With the method for the clean production of alumina by using low-grade diaspore bauxite of the present invention, a certain bauxite in Sanmenxia, Henan Province as described in Table 1 is still used as a raw material for the production process of alumina. As described below:

[0063] 1. The dealumination circulating liquid of Example 1 is prepared with NaOH solution until the NaOH concentration is 50%, mixed with a certain bauxite in Sanmenxia, Henan Province with a thickness of 74-150 μm, and stripping reaction is carried out in a high-pressure reactor, and the bauxite and hydrogen The mass ratio of the sodium oxide solution is 1:3, the stripping reaction temperature is 170°C, the reaction pressure is 0.45MPa, and the stripping time is 1 hour to obtain a solid-liquid mixture of the stripping solution containing sodium aluminate and slag, and the The relative dissolution rate of alumina is 99.4%;

[0064] 2. Cool the dissolved slag-containing suspension to 70°C for...

Embodiment 3

[0070] With the method for the clean production of alumina by using low-grade diaspore bauxite of the present invention, a certain bauxite in Sanmenxia, Henan Province as described in Table 1 is still used as a raw material for the production process of alumina. As described below:

[0071] 1. The dealumination circulating liquid in Example 2 is prepared with NaOH solution until the NaOH concentration is 60%, mixed with a certain bauxite in Sanmenxia, Henan Province of 74-150 μm, and stripping reaction is carried out in a high-pressure reactor, and the bauxite and hydrogen The mass ratio of the sodium oxide solution is 1:3, the stripping reaction temperature is 150°C, the reaction pressure is normal pressure, and the stripping time is 0.5 hours to obtain a solid-liquid mixture of the stripping solution containing sodium aluminate and slag, and the The relative dissolution rate of alumina is 93.2%;

[0072] 2. Cool the dissolved slag-containing suspension to 110°C for crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com