Thermosetting silicone resin composition, silicone resin, silicone resin sheet and use thereof

A silicone resin composition, thermosetting technology, applied in other home appliances, applications, home appliances, etc., can solve the problems of difficulty in forming a semi-cured state, difficulties, etc., and achieve the effect of excellent optical transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

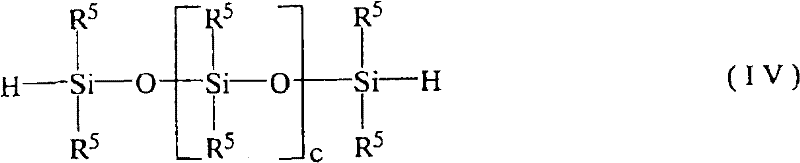

[0200] One hundred grams (8.70 mmol) of two-terminal silanol type silicone oil (manufactured by Shin-Etsu Chemical Co. Ltd., trade name: X-21-5842, average molecular weight: 11,500) was mixed by stirring. ), 0.86g (5.80mmol) of vinyltrimethoxysilane (manufactured by Shin-Etsu Chemical Industry Co., Ltd., trade name: KBM-1003) (wherein the SiOH group of the silanol type silicone oil at both ends is combined with vinyltrimethoxysilane The molar ratio of the methoxyl group (SiOH / methoxyl group)=17 / 17) and 10ml (8 parts by weight, based on the total amount of 100 parts by weight of the two-terminal silanol type silicone oil and vinyltrimethoxysilane) of 2 -propanol is mixed, then 0.16ml (0.17mmol, 2.0 moles based on 100 moles of both-terminal silanol type silicone oil) of tetramethylammonium hydroxide aqueous solution (concentration: 10% by weight) is added therein as a condensation catalyst, followed by Stir at room temperature (25°C) for 2 hours.

[0201] To the obtained oil, 0...

Embodiment 2

[0203] One hundred grams (8.70 mmol) of two-terminal silanol type silicone oil (manufactured by Shin-Etsu Chemical Co., Ltd., trade name: X-21-5842, average molecular weight: 11,500), 0.86 g (5.80 mmol) of ethylene were mixed by stirring. Trimethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd., trade name: KBM-1003) (the molar ratio of the SiOH group of the two-terminal silanol type silicone oil to the methoxy group of vinyltrimethoxysilane (SiOH / Methoxy) = 17 / 17) and 10ml (8 parts by weight, based on the total amount of 100 parts by weight of both-end silanol type silicone oil and vinyltrimethoxysilane) of 2-propanol are mixed, and then 0.16ml (0.17 mmol, 2.0 moles based on 100 moles of both-terminal silanol type silicone oil) tetramethylammonium hydroxide aqueous solution (concentration: 10% by weight) was added thereto as a condensation catalyst, followed by stirring at room temperature (25° C.) for 2 hours .

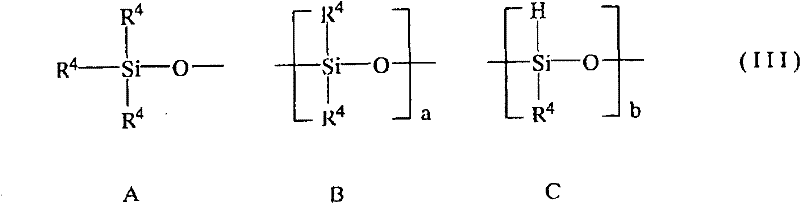

[0204] To the obtained oil, 0.090 g of organohydrogenp...

Embodiment 3

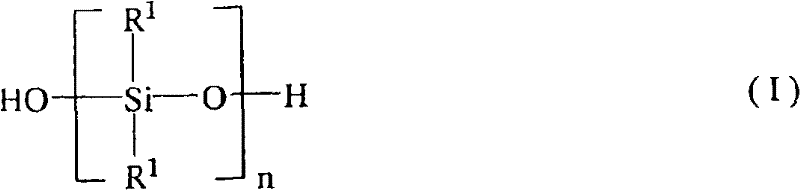

[0230] By stirring, two hundred grams (17.4 mmol) of two-terminal silanol type silicone oil (wherein the R of formula (I) 1 Groups are all represented by methyl compounds, average molecular weight: 11,500), 1.75g (11.8mmol) of vinyltrimethoxysilane (wherein R of formula (II') 2 The group is represented by a vinyl group and R of formula (II') 3 Groups are all represented by methyl groups) as a trialkoxysilane with an alkenyl group (wherein the SiOH group of the two-terminal silanol type silicone oil and the SiOR group of the trialkoxysilane with an alkenyl group 3 The molar ratio of groups (SiOH / SiOR 3 )=35 / 35) and 20ml (8 parts by weight, based on the total amount of 100 parts by weight of two-terminal silanol type silicone oil and trialkoxysilane with alkenyl group) of 2-propanol are mixed, and then 0.32ml ( 0.35mmol, based on 100 moles of two-terminal silanol type silicone oil is 2.0 moles of hydrogen oxidation

[0231] An aqueous solution of tetramethylammonium (concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com