Method for removing noxious substances in natural extract

A technology of natural extracts and harmful substances, applied in natural dyes, chemical instruments and methods, liquid solution solvent extraction, etc., can solve the problems of safety impact, safety problems, artificial pollution sources, etc., to achieve product safety improvement, international The effect of enhanced competitiveness and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

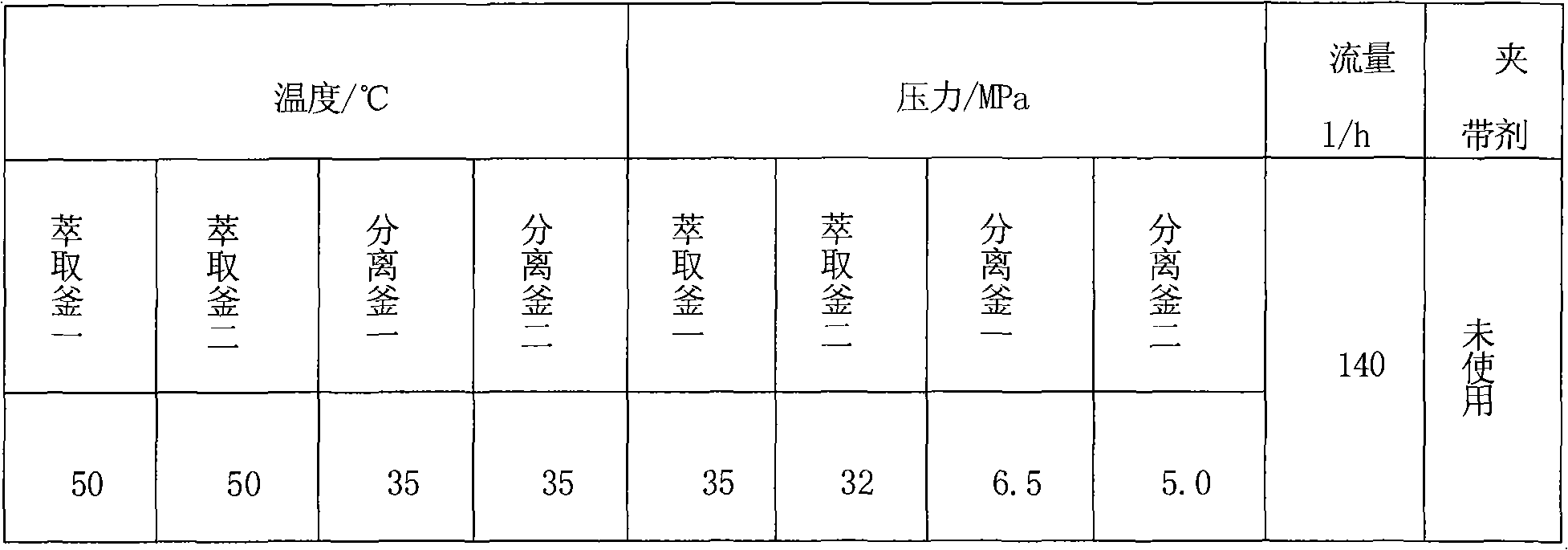

Embodiment 1

[0015] Embodiment 1: Get capsanthin oleoresin 9.8kg, add trace amount of Sudan red industrial dye wherein to be used for quantitative verification removal effect, after adding, Sudan red I content 2.1ppm, Sudan red II content 2.1ppm, Sudan red III content 1.8ppm , using a 24L*2 supercritical carbon dioxide extraction line for processing, put the oleoresin into the extraction kettle, adjust to the following conditions and keep it for 6.0 hours:

[0016]

[0017] After the above treatment, there was 8.0kg of capsanthin oleoresin remaining in the extraction kettle. After testing, Sudan I, Sudan II and Sudan III could not be detected, and the detection limit of various Sudan red monomers was 10ppb. Harmful substances are effectively removed, and the products meet international standards such as the United States, Japan, and the European Union.

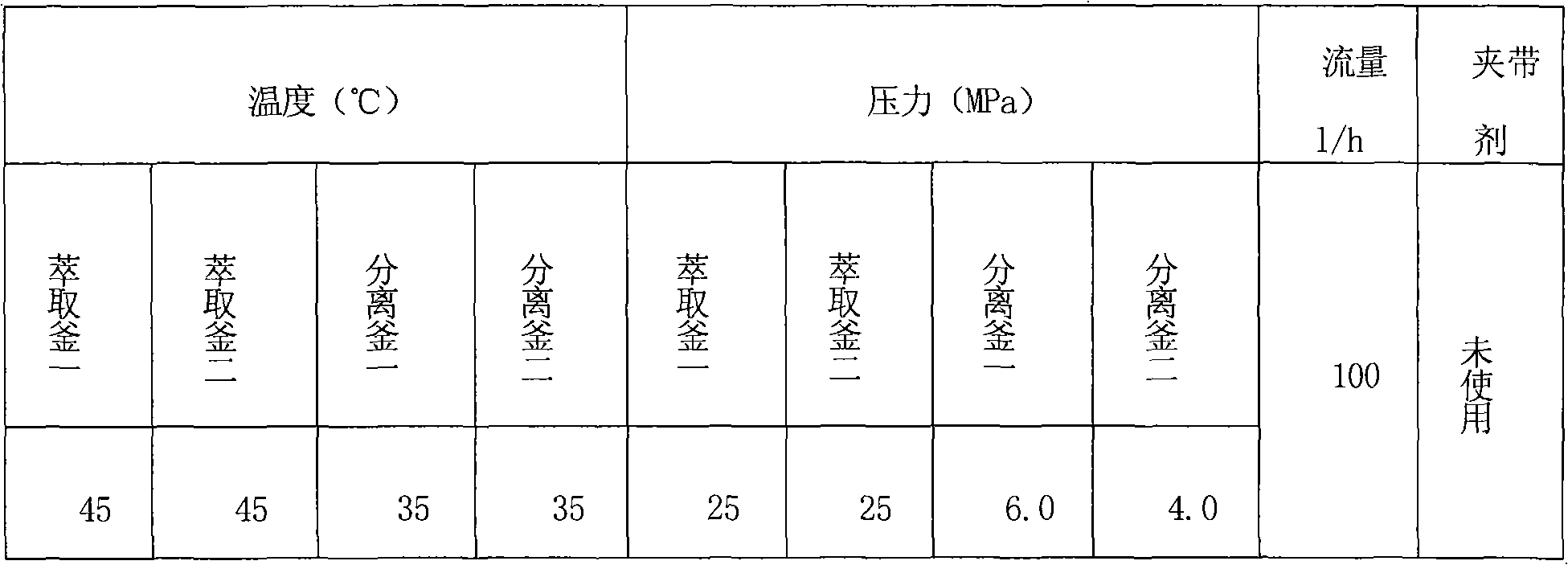

Embodiment 2

[0018] Embodiment 2: Get 10.5kg of lutein oleoresin, add trace synthetic antioxidant and pesticide to it and be used for quantitative verification removal effect, after adding, synthetic antioxidant ethoxyquinoline content 12ppm, cypermethrin content 2.5ppm, methylamine The phosphorus content is 5.0ppm, and the 24L*2 supercritical carbon dioxide extraction line is used for processing. The oleoresin is put into the extraction kettle, adjusted to the following conditions and kept for 4.0 hours:

[0019]

[0020] After the above treatment, 9.8kg of lutein oleoresin remained in the extraction kettle. After testing, ethoxyquinoline, cypermethrin and methamidophos were not detected, and ethoxyquinoline, cypermethrin and methamidophos were detected. The output limit is 10ppb.

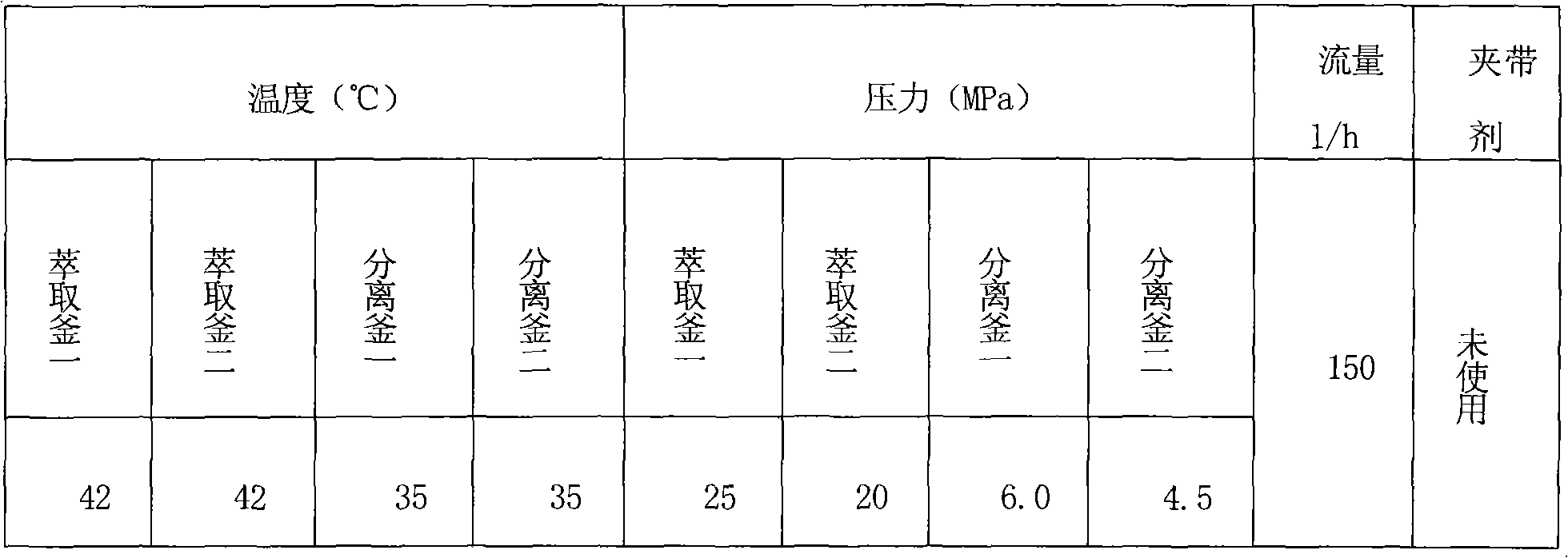

Embodiment 3

[0021] Example 3: Prepare 8.0 kg of lutein oleoresin containing dioxins and polychlorinated biphenyls, wherein the content of dioxins is 5.18 ng / kg, and the content of polychlorinated biphenyls is 1.02 ng / kg. Use a 24L*2 supercritical carbon dioxide extraction line for processing, put the lutein oleoresin into the extraction kettle, adjust to the following conditions and keep it for 5.0 hours:

[0022]

[0023] After the above treatment, 7.3 kg of lutein oleoresin remained in the extraction kettle, and the content of dioxins and polychlorinated biphenyls was 0.81 ng / kg and 0.08 ng / kg after testing. Meet the requirements of international standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com