Diamond bit and manufacturing method thereof

A diamond drill bit and a manufacturing method technology, applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve problems such as single performance and structure of the working layer, affect the geological drilling process, increase drilling cost, etc., and achieve long service life and good cutting edge , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

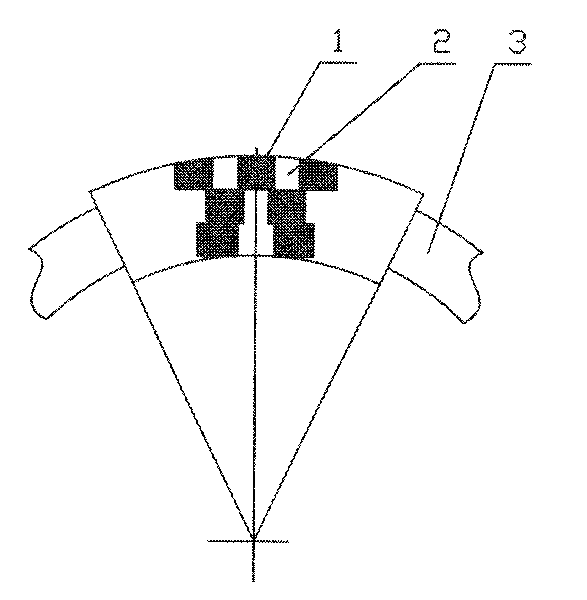

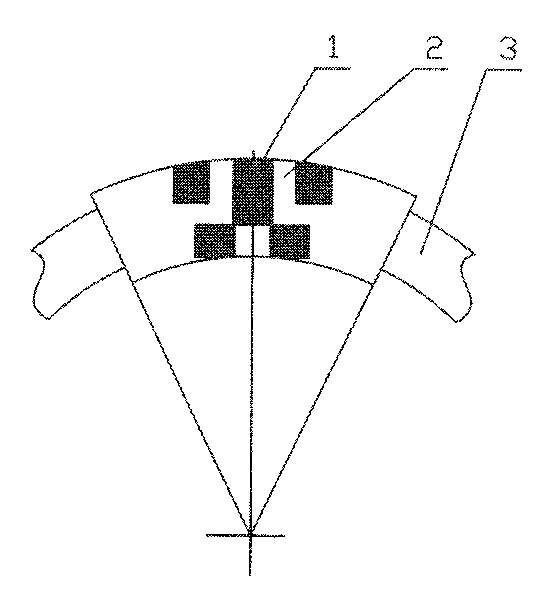

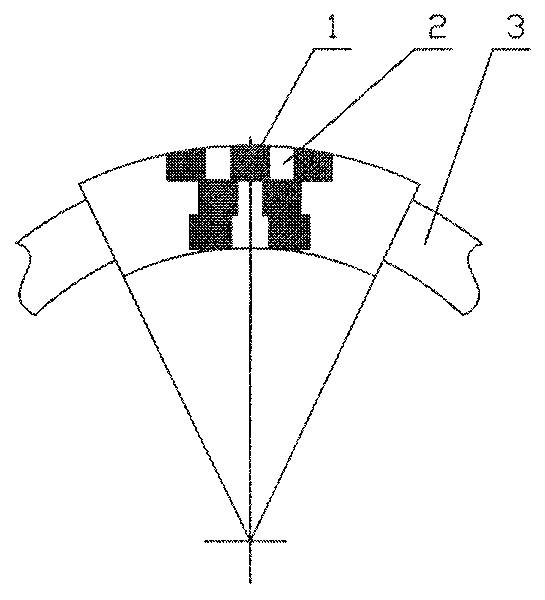

[0023] The hot-pressed diamond drill bit provided by the present invention includes a PCD sintered body 1 of the drill bit, a working layer matrix 2 and a nozzle nozzle 3 of the drill bit. Several PCD sintered bodies 1 are dispersed in the working layer carcass 2 . The diamond concentration in the diamond composite body is 95% to 100%, and the PCD sintered body 1 accounts for 55% to 70% of the working lip area of the drill bit; the hardness of the PCD sintered body 1 is HRc38 to 42, and the wear resistance is 0.35 to 0.45× 10-5ML. The material of the working layer matrix 2 of the drill bit is iron-nickel-manganese-cobalt-bronze alloy, in which iron accounts for 48% to 50%, nickel accounts for 12% to 16%, manganese accounts for 4% to 5%, and copper alloy accounts for 32% to 35%. %, its hardness is HRc22~HRc26, wear resistance is 0.48~0.55×10-5ML, the hardness of the drill matrix is low, and the wear resistance is low; the main function is to firmly wrap the PCD sintered bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com