Device for measuring six-dimensional position poses of object

A technology of object and pose, which is applied in the field of measuring the six-dimensional pose of objects, can solve the problem of high cost and achieve the effects of low cost, light weight and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

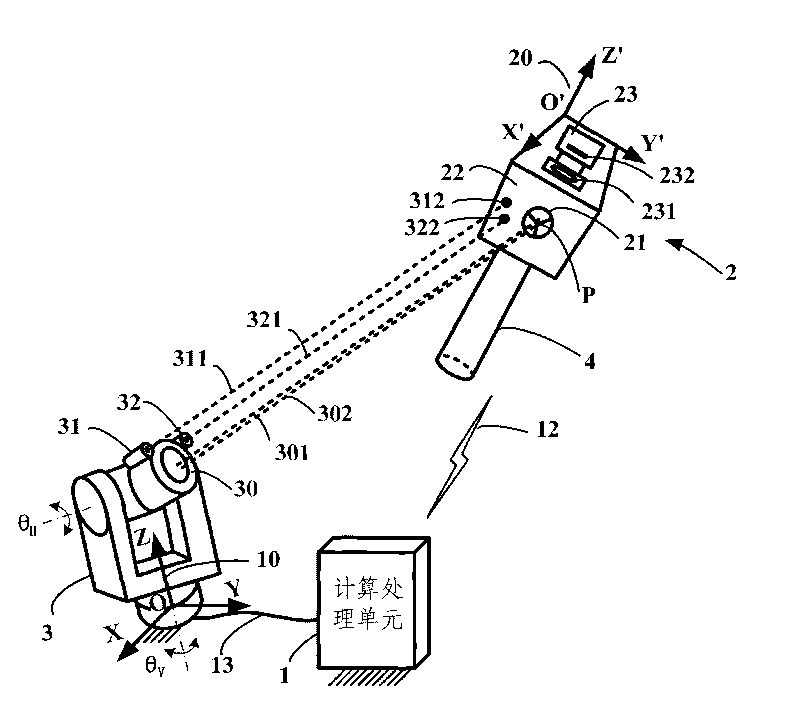

[0037] Such as figure 1 Shown is the first example of the six-dimensional pose measurement device proposed by the present invention, which is composed of a computing processing unit 1 , a receiver 2 and a laser tracker 3 . The laser tracker 3 is usually fixedly installed on the ground. The receiver 2 is installed on the moving object 4 whose six-dimensional pose is to be measured through a connecting piece or directly. In the figure, the receiver coordinate system 20 is O'-X'Y'Z', fixed on the receiver, while the global coordinate system 10 is O-XYZ, usually fixed on the laser tracker, and the moving object coordinate system is O m -X m Y m Z m (not shown), fixed on the moving object 4. Since the pose of the receiver coordinate system 20 relative to the moving object coordinate system is always fixed and can be obtained by a calibration method, measuring the six-dimensional pose of the moving object 4 is equivalent to measuring the receiver coordinate system 20 relative t...

Embodiment 2

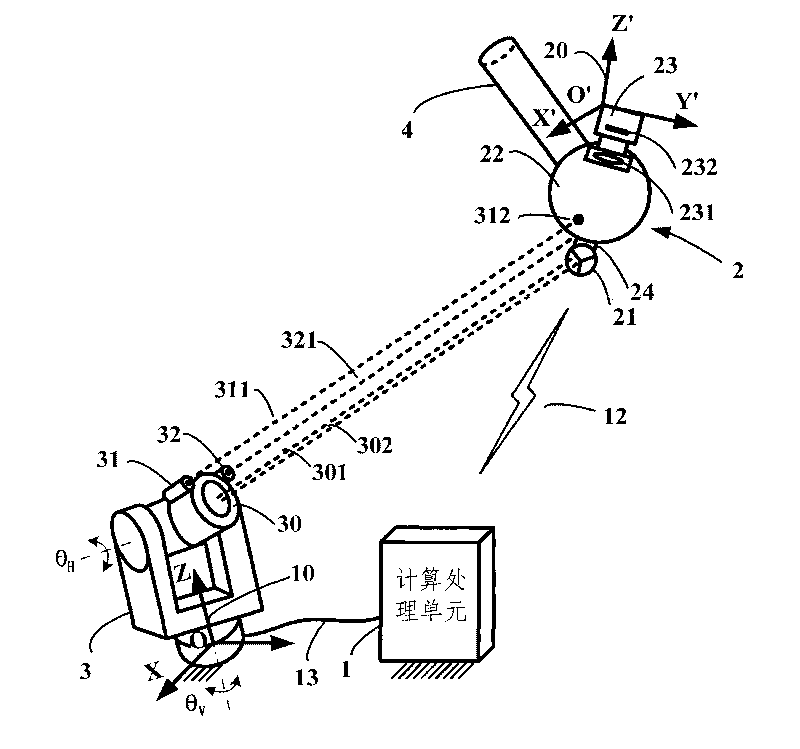

[0083] image 3 Shown is the second example of the six-dimensional pose measurement device proposed by the present invention. The difference from the first example is that the projection panel 22 on the receiver 2 adopts a spherical shape, and the imaging unit 23 is located on the inside of the projection panel; the projection panel 22 is provided with a magnetic support 24; The prism reflective ball can be reliably adsorbed on the magnetic support 24, and the operator can manually adjust the orientation of the retroreflector 21. The above two modifications can obtain a larger three-dimensional attitude measurement range. Of course, the magnetic support 24 can also be designed as a manual turntable or an automatic turntable with one degree of freedom or two degrees of freedom. Both the rotation axes of the manual turntable and the automatic turntable pass through the center of the prism reflective ball, which can keep the position of the center of the prism reflective ball re...

Embodiment 3

[0085] Figure 4 Shown is the third example of the six-dimensional pose measurement device proposed by the present invention. This example is mainly suitable for small-scale measurements. The rangefinder 30 on the laser tracker 3 is a structured light position sensor measured by triangulation method, which can be LK-G500 from Keyence Corporation of Japan, and the measurement range is 250mm-1000mm. Since triangulation is not suitable for measuring highly reflective surfaces, the retroreflector 21 is replaced in this example by a reflective patch. In this example, the projection panel 22 is made of a scattering and light-transmitting material, so that part of the incident laser light is diffusely reflected and part of it is diffusely transmitted. Therefore, the diffuse reflection function of the reflective patch can be realized by the projection panel 22 . In this example, the projection panel 22 is a spherical surface, but it may also be a plane or other curved surfaces. Sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com