Polyimide diaphragm for lithium ion secondary battery and lithium ion battery

A polyimide, secondary battery technology, applied in secondary batteries, battery pack parts, circuits, etc., can solve the problem of poor puncture resistance and high temperature safety performance of battery separators, and the size of polyimide membranes is not large. Uniformity and other issues, to achieve the effect of improving safety performance, uniform hole diameter distribution, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

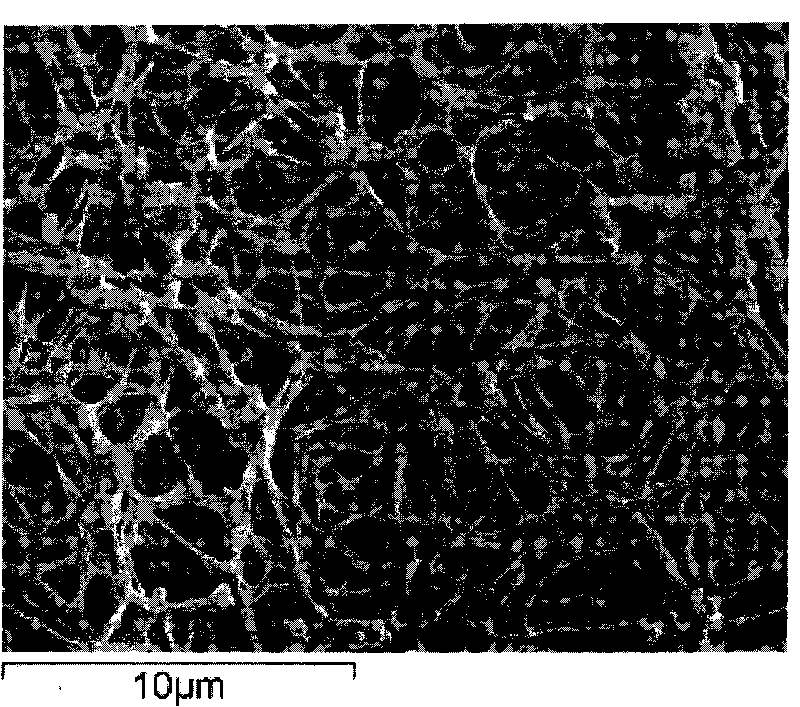

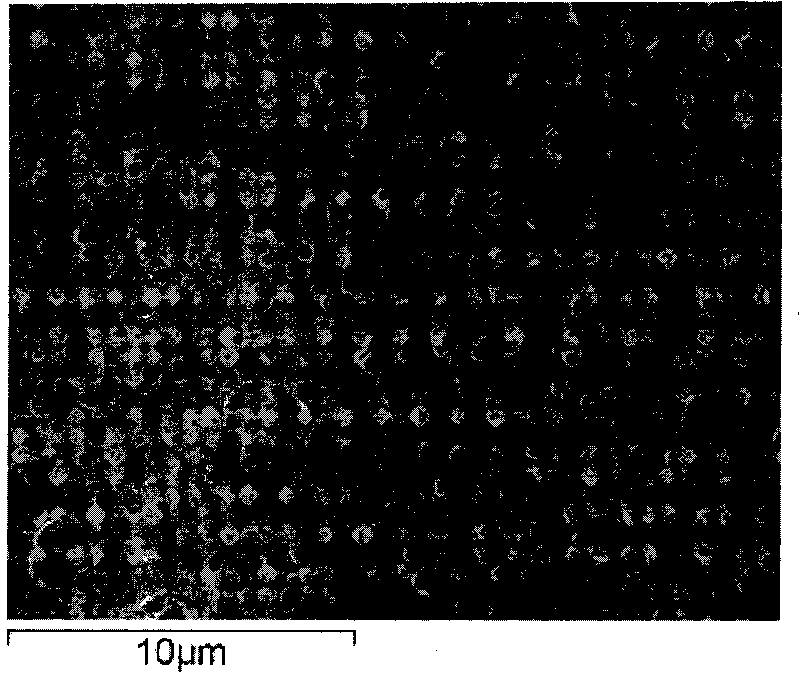

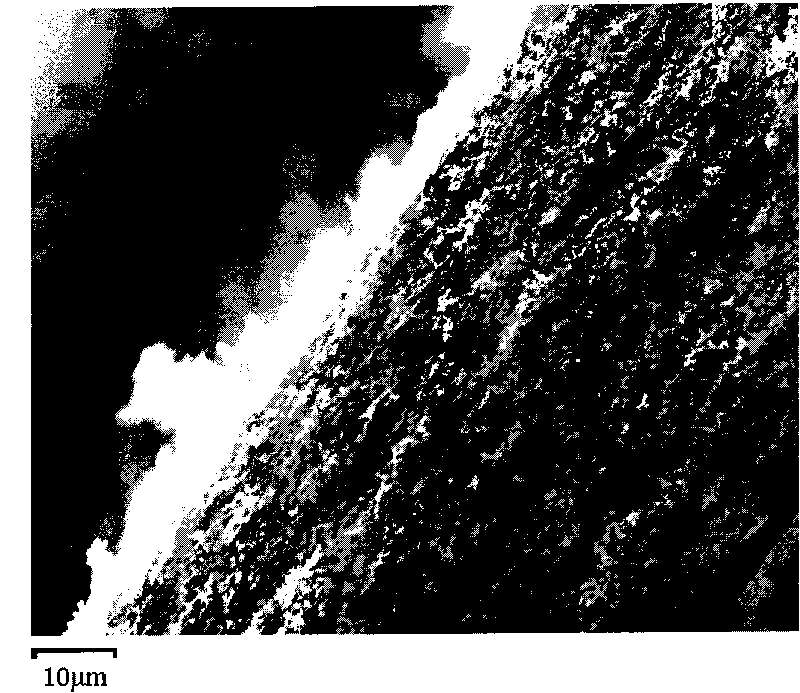

[0018] The preparation method of the polyimide diaphragm provided by the present invention comprises forming a polyamic acid membrane from a mixture containing polyamic acid, a pore-forming substance and a solvent, contacting the polyamic acid membrane with a coagulation solution, and performing imidization, The solvent is a solvent that dissolves polyamic acid but slightly dissolves or does not dissolve pore-forming substances, and the coagulation liquid is a liquid that dissolves pore-forming substances but slightly dissolves or does not dissolve polyamic acid. "Slightly soluble" described herein means that the solubility is less than 1 g / 100 g solvent and greater than 0.01 g / 100 g solvent; "insoluble" means that the solubility is less than 0.01 g / 100 g solvent.

[0019] Preferably, the weight ratio of the pore-forming substance to the polyamic acid is 0.01-0.3:1, the weight ratio of the polyamic acid to the solvent is 1:4.5-10, and the polyamic acid to the solidified The we...

Embodiment approach

[0053] According to a preferred embodiment of the present invention, the preparation method of polyimide membrane provided by the present invention comprises the steps:

[0054](1) Tetraacid dianhydride and organic diamine are added to the solvent according to the molar ratio of 0.8-1.2:1, the amount of solvent used is such that the concentration of the obtained polyamic acid is 5-40% by weight, at 20-70°C After stirring and reacting for 3-15 hours, add pore-forming substances, the weight ratio of pore-forming substances to the obtained polyamic acid is 0.01-0.3:1; vacuum degassing at the same temperature for 1-12 hours to obtain a polyamic acid solution;

[0055] (2) At a temperature of 10-40°C and a relative humidity of 20-80%, the above polyamic acid solution is coated on a stainless steel or glass support, dried at 20-200°C, and the solvent is removed to obtain 5 - 50 micron polyamic acid film;

[0056] (3) immersing the support body of the above-mentioned polyamic acid m...

Embodiment 1

[0070] (1) 4,4'-diaminodiphenyl ether and pyromellitic dianhydride are added to 300 milliliters of N,N-dimethylacetamide at a molar ratio of 1:1, wherein the solid content is 10% by weight . Stir the reaction at 25°C for 8 hours, then add 3 grams of propylene glycol methyl ether acetate, and vacuum degassing at this temperature for 1 hour to obtain a viscous mixture with an intrinsic viscosity η int =150 ml / g (measurement conditions: Ubbelohde viscometer, constant temperature 30°C, the mixture is diluted to a solid content of 0.005 g / ml);

[0071] (2) At a temperature of 10°C and a relative humidity of 50%, the above mixture is coated on a stainless steel plate, dried at 100°C for 20 minutes, and then the solvent is removed to obtain a polyamic acid film;

[0072] (3) Dip the above-mentioned stainless steel plate with polyamic acid film in 100 ml of coagulation solution composed of ethanol, ether and acetone (the volume ratio of ethanol, ether and acetone is 3:2:1) at 20°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com