Carbon foam material with core-shell structure and method for preparing carbon foam material

A core-shell structure and carbon foam technology, applied in the field of carbon foam preparation, can solve the problems of uneven distribution, large hole diameter and the like, and achieve the effects of simple and effective preparation process, high safety and reliable working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

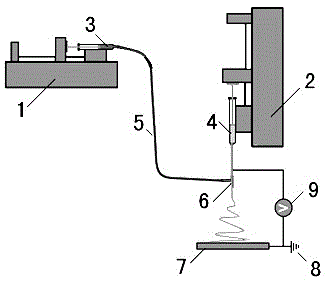

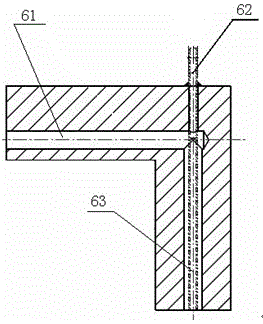

[0039] A carbon foam material with a core-shell structure, that is, a mixed solution of N, N-dimethylacetamide with a concentration of 3% (w / v) polyacrylonitrile and 1% (w / v) borneol as the sheath liquid , using acetone solution with a concentration of 20% (w / v) borneol as the core fluid, the distance between the nozzle of the coaxial nozzle and the receiving plate is controlled by a coaxial electrospray device to be 15cm, the voltage is 20kV, and the flow rate of the sheath fluid is 1.0 ml / h , the flow rate of the core liquid is 0.5 ml / h for spraying to obtain a film-like material;

[0040] Then dry the membrane material under the condition of elevated temperature and ventilation to obtain a solid mixed membrane material;

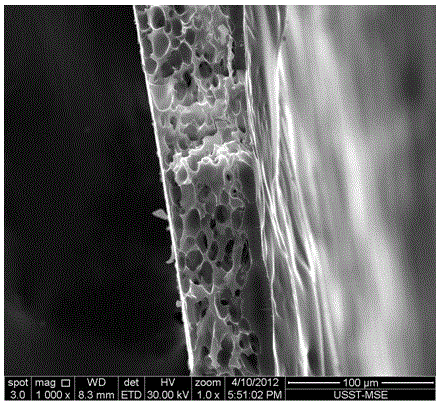

[0041] Then, pre-oxidize, carbonize, and high-temperature graphitize the solid mixed membrane material to obtain a carbon foam material with a core-shell structure.

[0042] The above-mentioned preparation method of a carbon foam material with a core-shel...

Embodiment 2

[0054] A carbon foam material with a core-shell structure, that is, a mixed solution of N, N-dimethylacetamide with a concentration of 3% (w / v) polyacrylonitrile and 1% (w / v) borneol as the sheath liquid , using acetone solution with a concentration of 20% (w / v) borneol as the core liquid, the distance between the nozzle of the coaxial nozzle and the receiving plate is controlled by a coaxial electrospray device to be 15cm, the voltage is 20kV, and the flow rate of the sheath liquid is 3.0 ml / h , the flow rate of the core liquid is 1.0ml / h to spray to obtain a film-like material;

[0055] Then dry the membrane material under the condition of elevated temperature and ventilation to obtain a solid mixed membrane material;

[0056] Then, pre-oxidize, carbonize, and high-temperature graphitize the solid mixed membrane material to obtain a carbon foam material with a core-shell structure.

[0057] The above-mentioned preparation method of a carbon foam material with a core-shell s...

Embodiment 3

[0060] A carbon foam material with a core-shell structure, that is, a mixed solution of N, N-dimethylacetamide with a concentration of 3% (w / v) polyacrylonitrile and 1% (w / v) borneol as the sheath liquid , using acetone solution with a concentration of 20% (w / v) borneol as the core liquid, the distance between the nozzle of the coaxial nozzle and the receiving plate is controlled by a coaxial electrospray device to be 15cm, the voltage is 20kV, and the flow rate of the sheath liquid is 0.5ml / h , the flow rate of the core fluid is 0.1ml / h to spray to obtain a film-like material;

[0061] Then dry the membrane material under the condition of elevated temperature and ventilation to obtain a solid mixed membrane material;

[0062] Then, pre-oxidize, carbonize, and high-temperature graphitize the solid mixed membrane material to obtain a carbon foam material with a core-shell structure.

[0063] The above-mentioned preparation method of a carbon foam material with a core-shell str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com