Method for preparing particles comprising metal oxide coating and particles with metal oxide coating

A technology of oxide coating and oxide layer, applied in chemical instruments and methods, botanical equipment and methods, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0064] According to a preferred embodiment of the present invention, the method includes:

[0065] (a) contacting a solid water-insoluble particulate material with a first cationic additive and an aqueous medium so as to obtain a dispersion of said particulate material positively charged on its surface;

[0066] (b) subjecting said particulate matter to a coating process comprising precipitating a metal oxide salt on the surface of said particulate material to form a metal oxide coating on said particulate material;

[0067] (b1) in an aqueous medium, contacting the coated particulate matter with a surface binding additive which is (i) a second cationic additive and / or (ii) a nonionic additive;

[0068] (b2) performing a coating process as in step (b) on the particulate matter obtained in step (b1);

[0069] (c) repeating steps (b1) and (b2) at least 3 more times; and

[0070] (d) aging the metal oxide coating.

[0071] The method preferably comprises repeating step (c) 3 t...

Embodiment

[0261] In the following examples, all % values relating to solutions are by weight. All % values referring to dispersions are by weight.

[0262] Unless otherwise stated, all solutions used in the following examples refer to aqueous solutions of the stated ingredients.

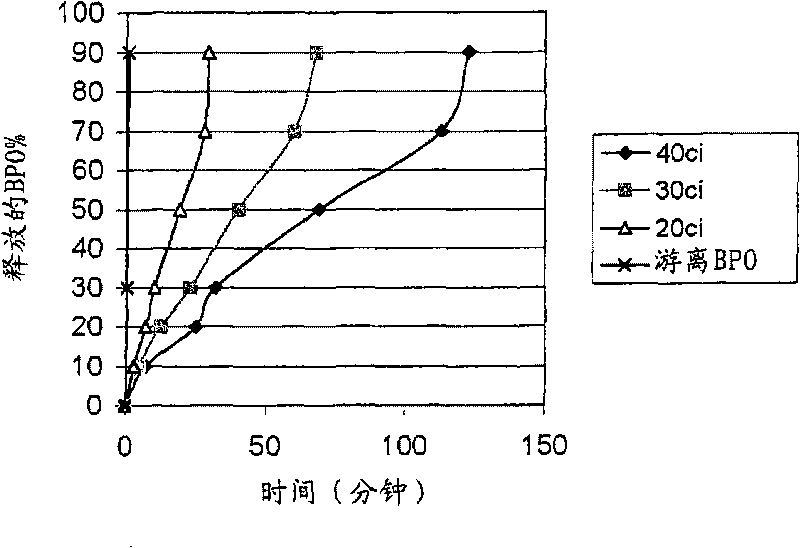

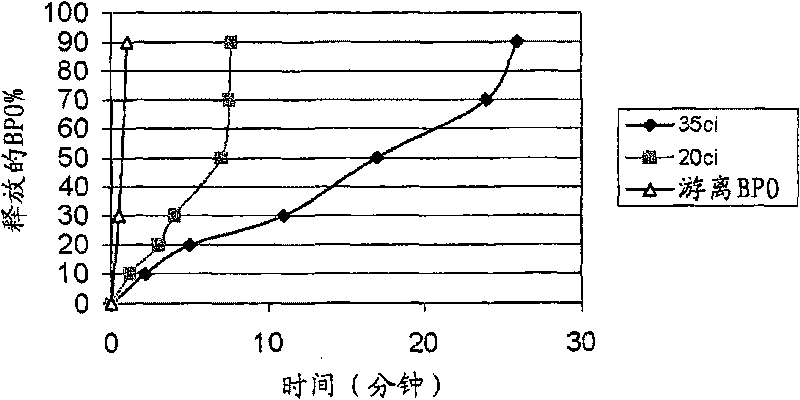

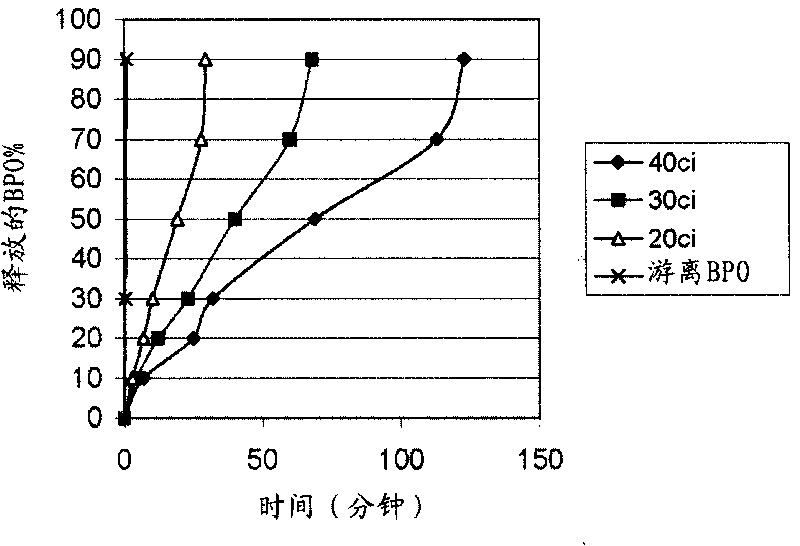

[0263] Example #1: Silica Coating of BPO

[0264] Step 1: Grinding: 110 g of aqueous BPO 75% (USP grade from Sigma) were suspended in 152 g of a 0.4% CTAC solution containing 0.001% silicon antifoam. The BPO was milled with a rotor rotor mixer (Kinematika polytron 6100, operating at 15,000 rpm / 25m / s). Milling was stopped when the particle size distribution (PSD) of the suspension was d(0.9)<35 μm or the temperature reached 50°C. The final suspension was cooled to room temperature.

[0265] Step 2a: Coating Option #1: The suspension was stirred at 500 RPM with a mechanical dissolver (80 mm) throughout the coating process. The pH of the ground BPO suspension was corrected to 8 with 5N NaOH solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com