Energy-saving grain drying equipment

A technology for drying equipment and grains, applied in food processing, preservation of seeds by drying, climate change adaptation, etc., can solve the problems of inability to use dry grains, waste of heat energy, environmental pollution, etc., and is conducive to environmental protection and reduces manufacturing cost, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

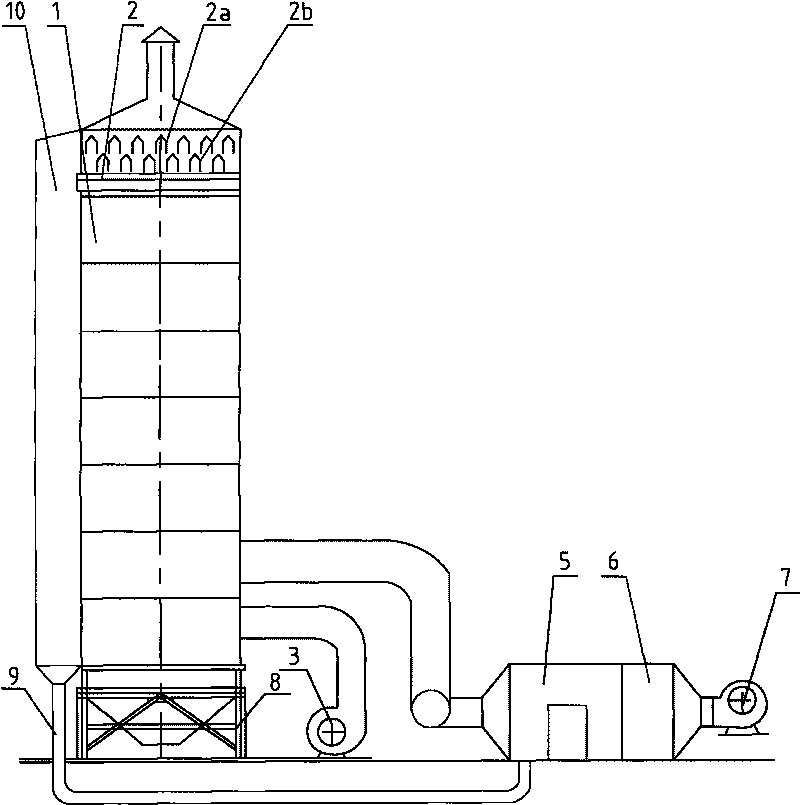

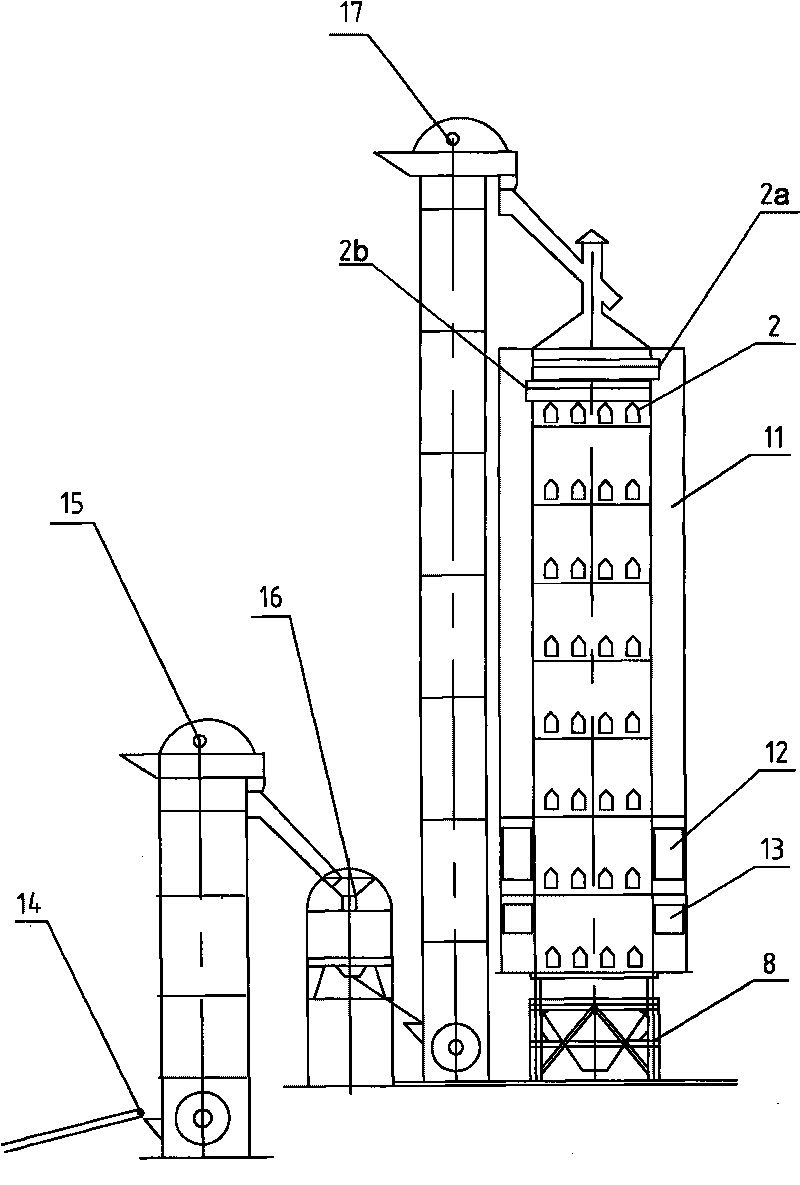

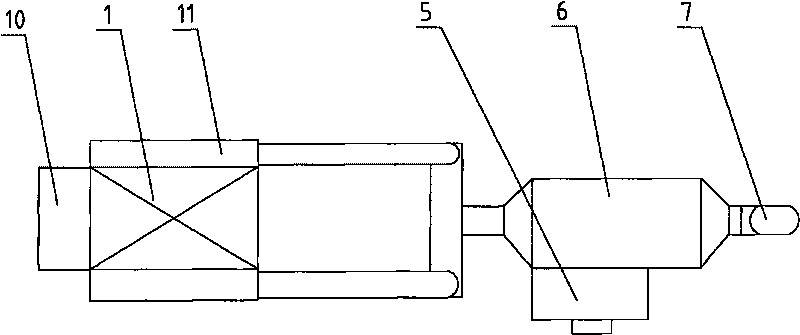

[0015] Depend on Figure 1-4 Shown, main structure of the present invention comprises that it comprises the drying tower 1 that is made up of grain storage section, drying section, slow-down section, cooling section, drying tower feeding device, and this feeding device includes conveyer 14, primary Elevator 15, primary cleaning screen 16 and secondary elevator 17, hot blast stove 6, air cooler 3, four-blade mechanism grain discharge device at the bottom of the drying tower and column tower 8, and three layers are evenly distributed in each section of the drying tower Angular air tanks, wherein the gas outlets of the lowermost angular air tanks 2 in each section are on the side of the drying tower and connected to the waste heat collection chamber 10, which is connected to the water-gas separator 5 through the insulation pipe 9, each The lowermost angular air grooves 2 in the section are perpendicular to the upper angular air grooves 2a, 2b. Both sides of the drying tower are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com