Cassava leaf extract and preparation method and application thereof

A technology of cassava leaves and extracts, which is applied in the field of cassava leaf extracts and its preparation and application, can solve the problems of denaturation of proteins and other components, no plant leaves, and influence on product quality, so as to improve the comprehensive utilization rate and agricultural The effect on gross output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

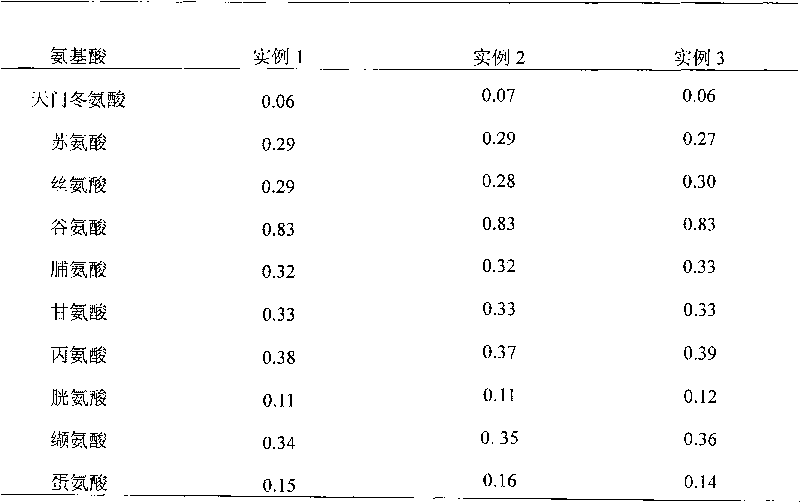

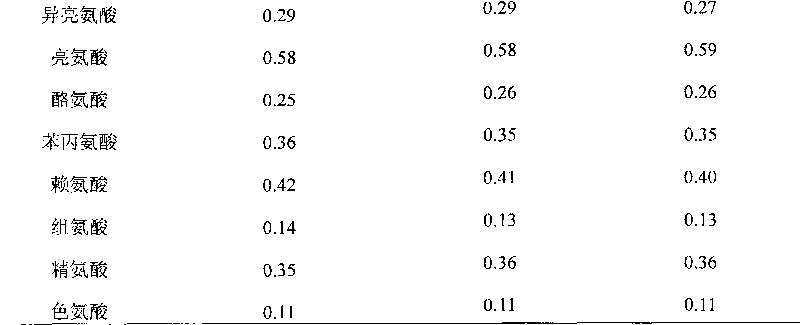

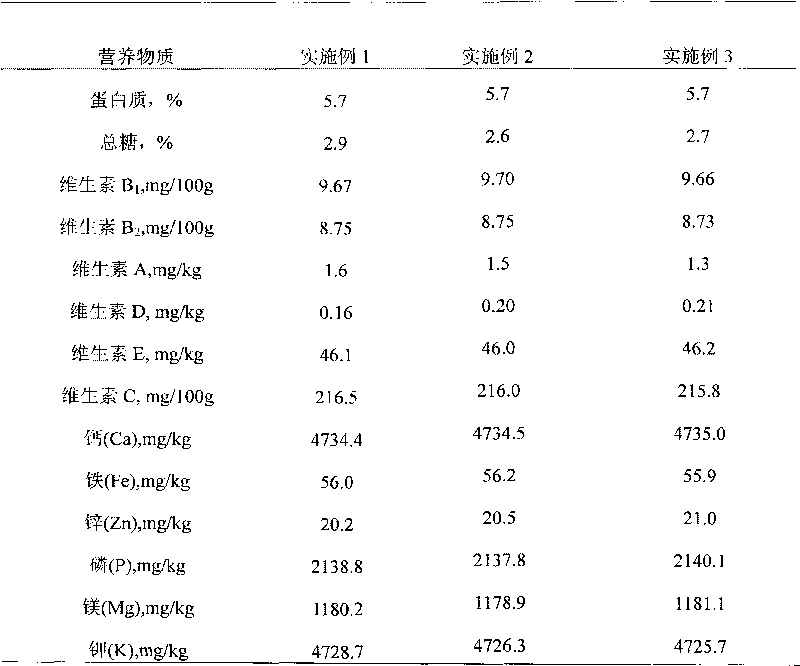

Examples

Embodiment 1

[0028] Embodiment 1, preparation cassava leaf solid beverage

[0029] 1) Pre-treatment of raw materials: Fresh cassava leaves (collected in Chinese cassava planting bases, such as Hainan, Guangxi and other provinces) are cleaned of impurities and yellow leaves, washed with drinking water, drained and placed in a blast drying oven at 100°C Inactivate in the environment for 10 minutes, then take it out, when the temperature of the oven drops to 50°C, put the cassava leaves after drying, and continue to dry until the water content is less than 5%. After cooling, use a sample grinder and a cyclone mill Crush and pass through 40 meshes.

[0030] 2) Active ingredient extraction: Weigh 2kg of leaf powder, add 20L of deionized water, soak at room temperature for 30 minutes, control the temperature at 40°C, and add 0.6% protease of leaf powder mass under the condition of pH4.0 (the protease is 1398 Protease, the activity is 100,000-200,000 IU / g, purchased from Wuxi Enzyme Preparation ...

Embodiment 2

[0035] Embodiment 2, the concrete steps of the processing method of preparing cassava leaf solid beverage comprise:

[0036] 1) Pretreatment of raw materials: Fresh cassava leaves are cleaned of impurities and yellow leaves, washed with drinking water, drained, put into a blast drying oven at 105°C for 8 minutes, then taken out, and waited until the temperature of the oven drops to At 55°C, put the greened cassava leaves in and continue to dry until the water content is less than 3%. After cooling, grind them with a sample grinder and a cyclone mill, and pass through 60 meshes.

[0037] 2) Active ingredient extraction: Weigh 1.5kg of leaf powder, add 18L of deionized water, soak at room temperature for 60 minutes, control the temperature at 70°C, and add 1.4% protease (the protease is 1398 Neutral protease, with an activity of 100,000-200,000 IU / g, was purchased from Wuxi Enzyme Preparation Factory). Constant temperature extraction for 16 hours.

[0038] 3) Concentration and...

Embodiment 3

[0042] Embodiment 3, preparation cassava leaf solid beverage

[0043] 1) Pretreatment of raw materials: Fresh cassava leaves are cleaned of impurities and yellow leaves, washed with drinking water, drained, put into a blast drying oven at 105°C for 15 minutes, and then taken out, until the temperature of the oven drops to At 60°C, add the greened cassava leaves and continue to dry until the water content is less than 3%. After cooling, grind them with a sample grinder and a cyclone mill, and pass through 80 meshes.

[0044] 2) Active ingredient extraction: Weigh 1.0kg leaf powder, add 10L deionized water, soak at room temperature for 40 minutes, control temperature at 60°C, and add 2% protease of leaf powder mass (the protease is 1398 Neutral protease, with an activity of 100,000-200,000 IU / g, was purchased from Wuxi Enzyme Preparation Factory). Constant temperature extraction for 16 hours.

[0045] 3) Concentration and deodorization: Concentrate the above hydrolyzate on a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com