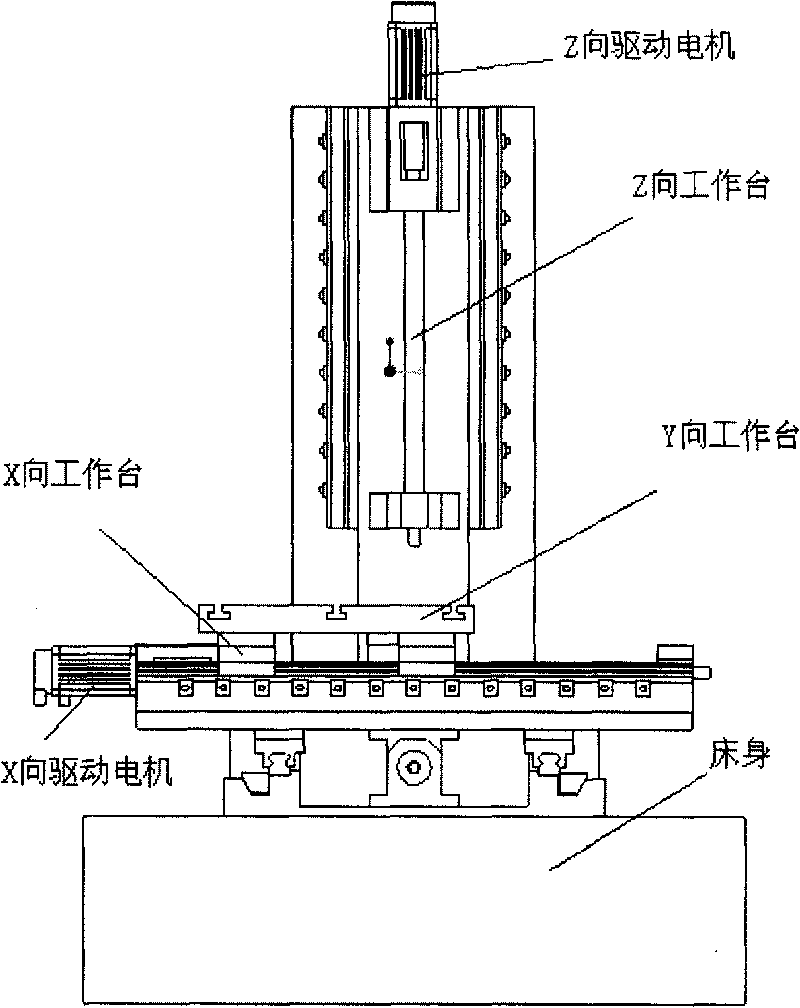

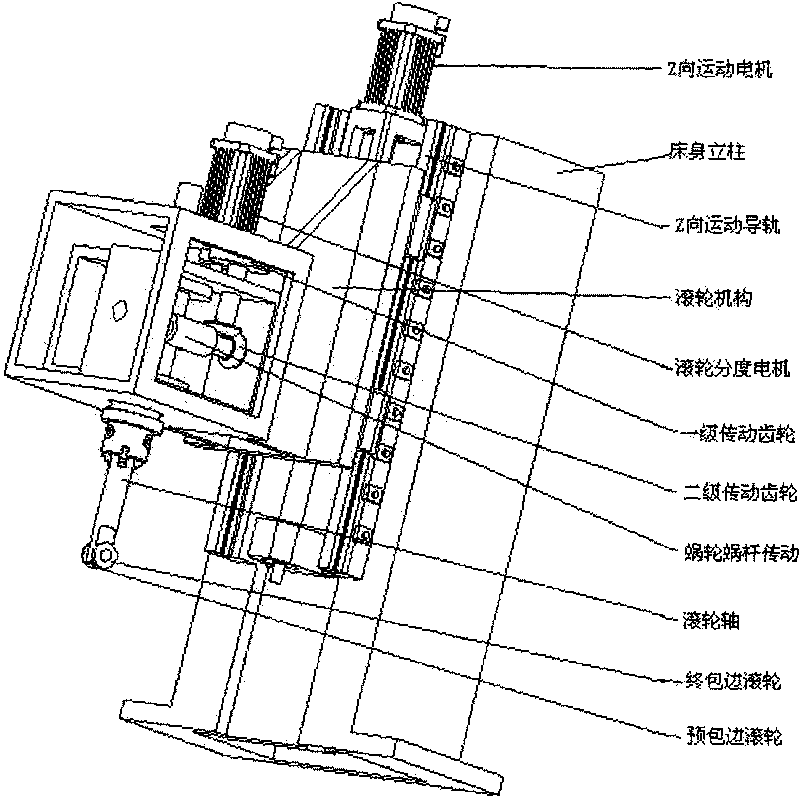

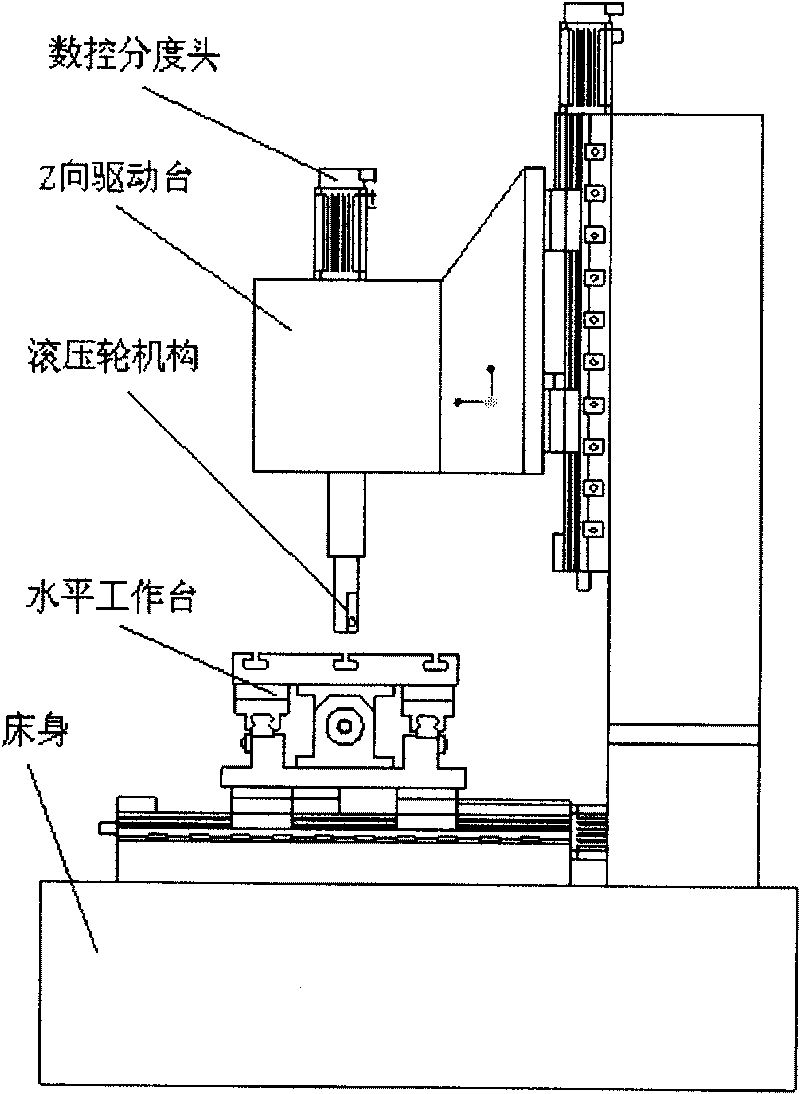

Novel numerical control rolling taping machine

A rolling wrapping and wrapping technology, which is applied in the direction of large fixed members, metal processing machinery parts, precision positioning equipment, etc., can solve the problems of roughness of the periphery, reduction of equipment rigidity, wrinkling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to the following examples.

[0039]Select the ordinary car door structure, the inner panel and guide rail of the door, and complete the connection in advance by spot welding. The inner body and the outer panel of the welded parts are pre-connected through the two pre-processed connection process holes through rivets, and then It is accurately positioned on the hemming tire mold designed according to the structural characteristics of the car door through the feeding mechanism, and multiple fixtures are reasonably arranged on the hemming workbench. The basic principle of the arrangement is to make the clamping points of the car door as uniform as possible to avoid deformation of parts. After the part is clamped, perform the origin positioning operation of the hemming process, and set the system origin and the workpiece origin position, input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com