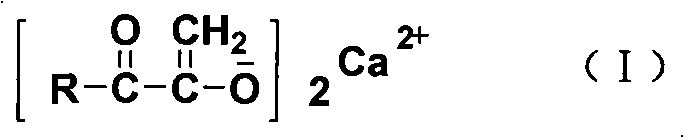

Method for preparing alpha-calcium picrolonate

A technology of calcium keto acid and keto acid, applied in the field of preparation of calcium α-keto acid, can solve problems such as environmental pollution and increase cost, and achieve the effect of easy separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] At 25°C, 69.6 grams, 0.6 moles of 3-methyl-2-oxobutanoic acid were added to a 1000ml three-necked flask, 400ml of purified water was added, stirred, the pH value was adjusted to 5 with calcium carbonate, and the stirring was continued for one hour. After the reaction was completed, the reaction solution was extracted with 200 ml of ethyl acetate, and the organic layer was concentrated to recover unreacted acid. The aqueous layer was concentrated to dryness, and the residue was crystallized with water to obtain 57.2 g of a white solid, with a yield of 70.6%.

Embodiment 2

[0021] At 25°C, add 130 grams, 1 mole of 4-methyl-2-oxopentanoic acid into a 1000ml three-necked flask, add 700ml of purified water, stir, adjust the pH value to 4.5 with calcium bicarbonate, and continue stirring for one hour . After the reaction was completed, the reaction solution was extracted with 350 ml of ethyl acetate, and the organic layer was concentrated to recover unreacted acid. The aqueous layer was concentrated to dryness, and the residue was crystallized with water to obtain 121 g of a white solid with a yield of 81.2%.

Embodiment 3

[0023] At 25°C, add 130 grams, 1 mole of 3-methyl-2-oxopentanoic acid into a 1000ml three-necked flask, add 700ml of purified water, stir, adjust the pH value to 5 with calcium carbonate, and continue stirring for one hour. After the reaction was completed, the reaction solution was extracted with 350 ml of ethyl acetate, and the organic layer was concentrated to recover unreacted acid. The aqueous layer was concentrated to dryness, and the residue was crystallized with water to obtain 116 g of a white solid with a yield of 77.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com