Method for extracting and separating huperzine A from huperizia serrata

A technology for Huperzine A and Huperzine serrata, applied in the field of extraction and separation of Huperzine A, can solve the problems of high price of raw materials of Huperzine A, difficult plant source of Huperzine serrata, long growth cycle and the like, and achieves enhanced The effect of market competitiveness, simplified operation and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

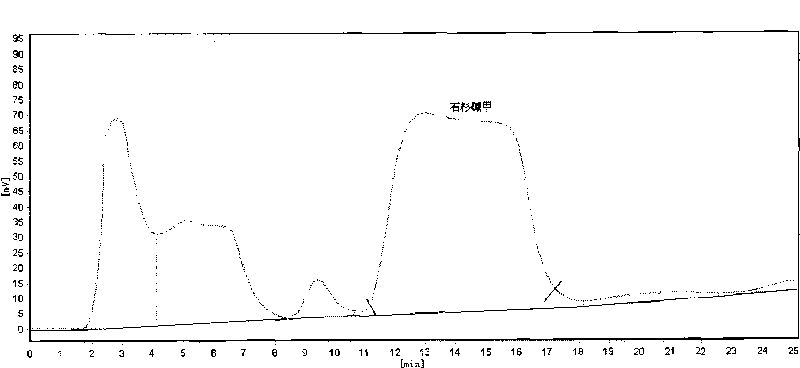

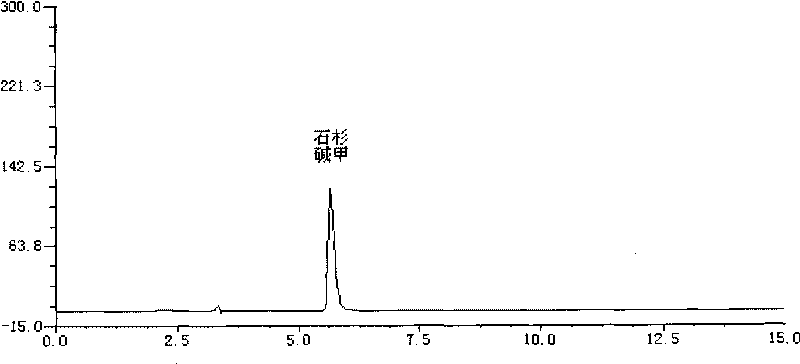

[0027] Take 50 g of Huperzia serrata with a crushed mesh of 20 meshes, and extract 4 times with 375 mL of 2% acetic acid solution under stirring at room temperature for 2 hours. The three or four times the extraction liquid is used as the circulating extraction solvent, and the pH of the extraction liquid is adjusted to 9 with ammonia water, and then filtered.

[0028] The SP825 macroporous adsorption resin column was wet-packed in a glass column. After pretreatment according to the method provided by the manufacturer, the pH 9.0 extract was loaded onto the column at a speed of 6BV / h, and the end of the sample loading was monitored by TLC. After saturation, 90% methanol was used as the eluent, and the flow rate was 6 BV / h. Collect the eluate containing the part of Huperzine A, quickly concentrate in vacuum, and dry to obtain crude Huperzine A I.

[0029] 200~300 mesh basic alumina is wet-packed in a 40*300 stainless steel chromatography column with mobile phase, 3390 mg of Huperzi...

Embodiment 2

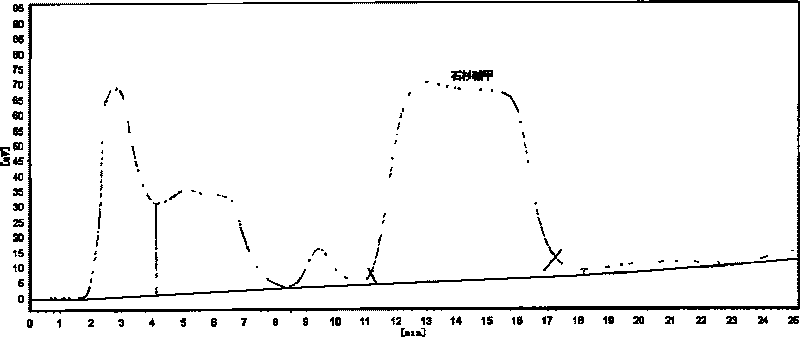

[0032] Weigh 8Kg of the raw material powder into a 100-liter multifunctional extractor, add 60 liters of 2% acetic acid, stir and extract at room temperature for 2 hours, filter, extract 4 times, and combine the 4 extracts to obtain a total volume of 231 liters of the extract. Adjust the pH of the extract to 9.0 with ammonia and filter.

[0033] The SP825 macroporous adsorption resin column was wet-packed in a glass column. After pretreatment according to the method provided by the manufacturer, the pH 9.0 extract was loaded onto the column at a speed of 6BV / h, and the end of the sample loading was monitored by TLC. After saturation, 90% methanol was used as the eluent, and the flow rate was 6 BV / h. Collect the eluate containing the part of Huperzine A, quickly concentrate in vacuum, and dry to obtain crude Huperzine A I.

[0034] 200~300 mesh basic alumina was packed in 110*1200 stainless steel chromatography column by mobile phase wet method, 103 grams of Huperzine A crude I was...

Embodiment 3

[0037] Weigh 200Kg of raw material powder into a 2000 liter extraction tank, add 1500 liters of 2% acetic acid, stir and extract at room temperature for 2 hours, filter, extract 4 times, and combine the 4 extraction solutions. Adjust the pH of the extract to 9.0 with ammonia.

[0038] The SP825 macroporous adsorption resin column is wet-packed in a stainless steel resin column. After pretreatment according to the method provided by the manufacturer, the pH9.0 extract is loaded onto the column at a speed of 6BV / h, and the end point of the sample loading is monitored by TLC. After saturation, 90% methanol was used as the eluent, and the flow rate was 6 BV / h. Collect the eluate containing the part of Huperzine A, quickly concentrate in vacuum, and dry to obtain crude Huperzine A I.

[0039] 200~300 mesh basic alumina is packed in 110*1200 stainless steel chromatography column by mobile phase wet method, Huperzine A crude product I is divided into several times for basic alumina colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com