Vertical structure oxidation bed of mine ventilation air methane gas thermal oxidation device

An oxidation bed and wind gas technology, applied in safety devices, mining equipment, earthwork drilling and mining, etc., can solve problems such as difficult to meet requirements, achieve the effects of prolonging the airflow reversing period, improving stability, and reducing lateral backlog stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

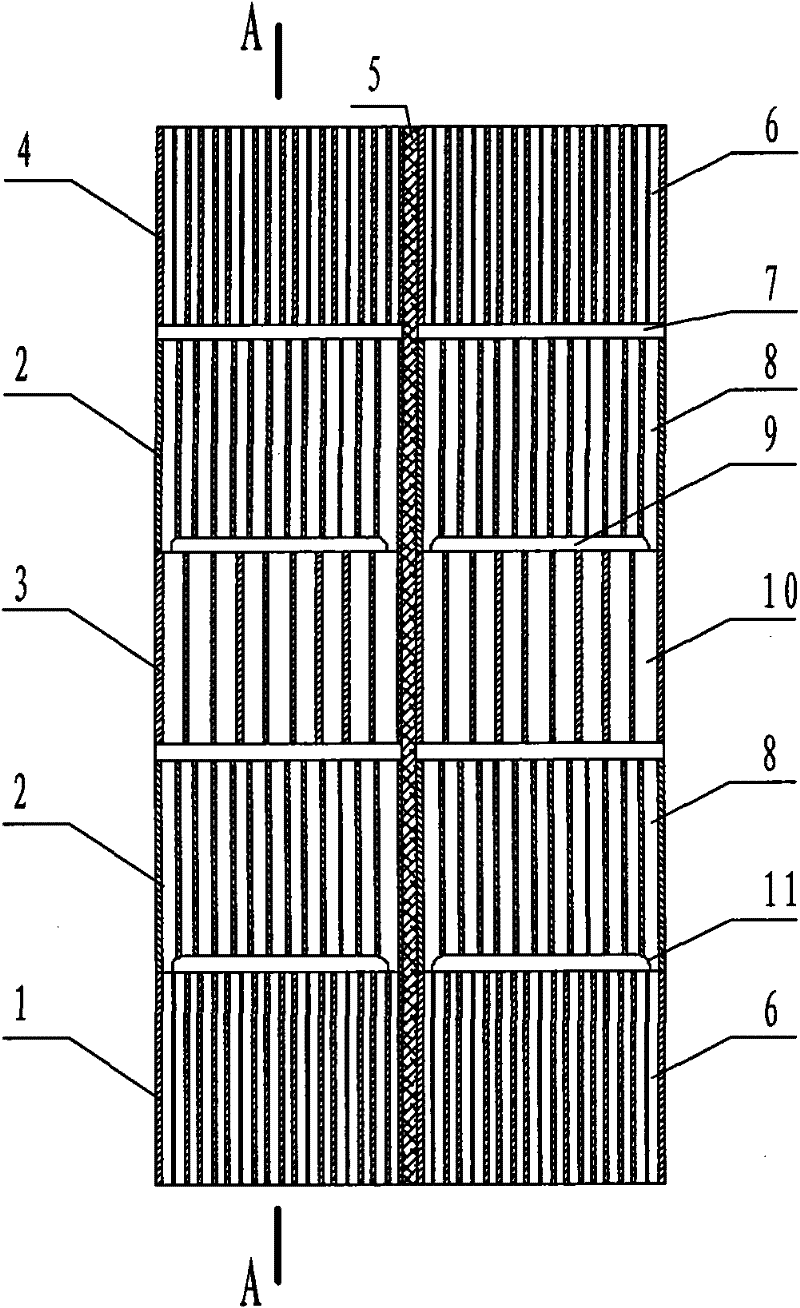

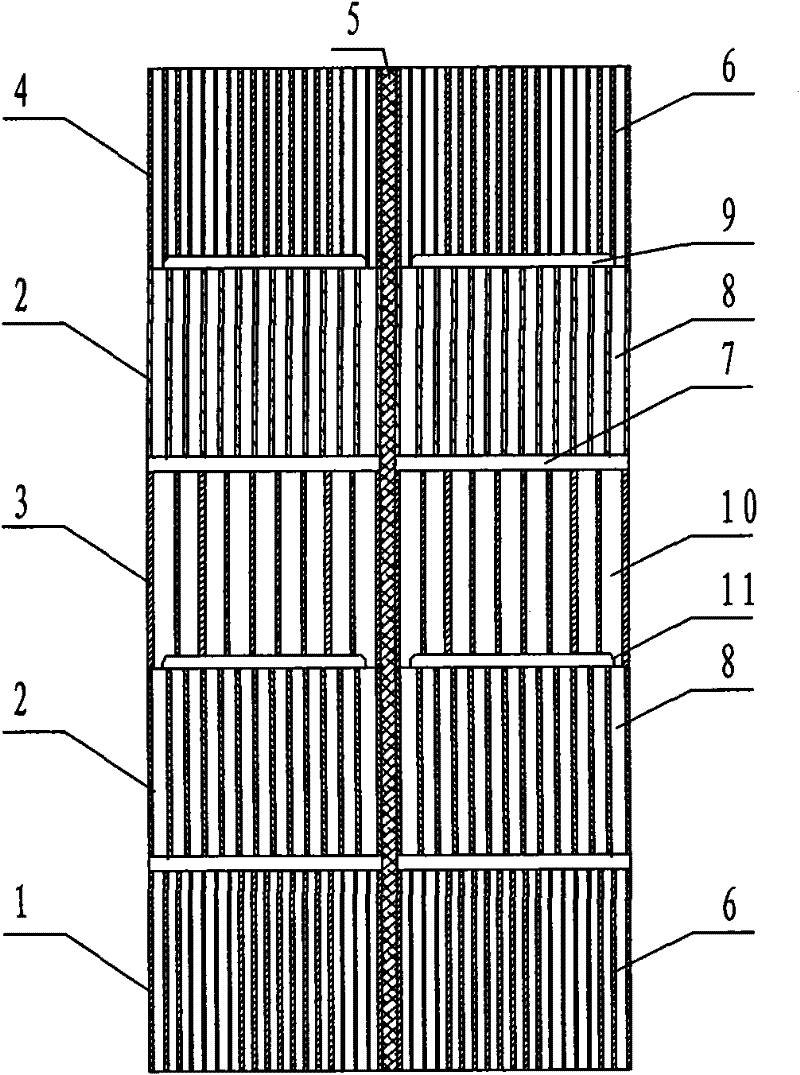

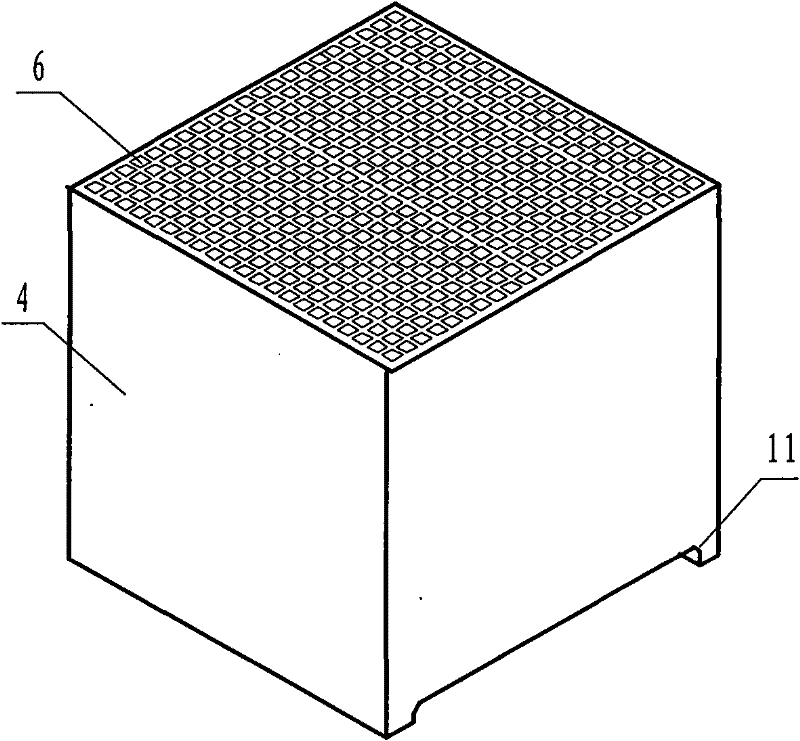

[0018] exist Figure 1-4 In the shown embodiment: the oxidation bed is composed of three kinds of honeycomb ceramics 1 arranged and stacked. The honeycomb ceramics 1 arranged in the middle of the oxidation bed adopts a honeycomb ceramic with a large equivalent diameter of pores, a high opening rate, and high temperature resistance, and the pores 2 are positive six. The two-layer honeycomb ceramics located on the upper and lower sides of the honeycomb ceramics 1 in the middle of the oxidation bed have strong thermal shock resistance, and take the middle of the oxidation bed as a plane of symmetry, and the equivalent diameter of the pores and the open porosity decrease stepwise from the inside to the outside. Hole 2 is in the shape of a regular quadrilateral; grooves 3 in the same direction are provided between the bonding surfaces of the same layer adjacent to the upper and lower honeycomb ceramics 1, the depth of groove 3 is 2mm, and the right angles of groove 3 are in the shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com